- Zunyi, Guizhou is accelerating the construction of a bio carbon based solid-state battery base with a total investmen of 14 billion yuan

- This project will not only fill the industrial gap in Guizhou, but also transform local bamboo and aluminum resources into high-end

Under the guidance of the dual carbon target, the map of China's new energy industry is accelerating its extension to the western and inland regions. On December 6, 2025, a bio carbon based solid-state battery super project with a total investment of up to 14 billion yuan is turning from blueprint to reality. This is not only the landing of a single factory, but also marks the "Guizhou Path" of exchanging resource advantages for industrial advantages, which is making a loud voice in the next generation battery technology competition.

The 'Ultimate Battery' Solution Originating from Bamboo Grove

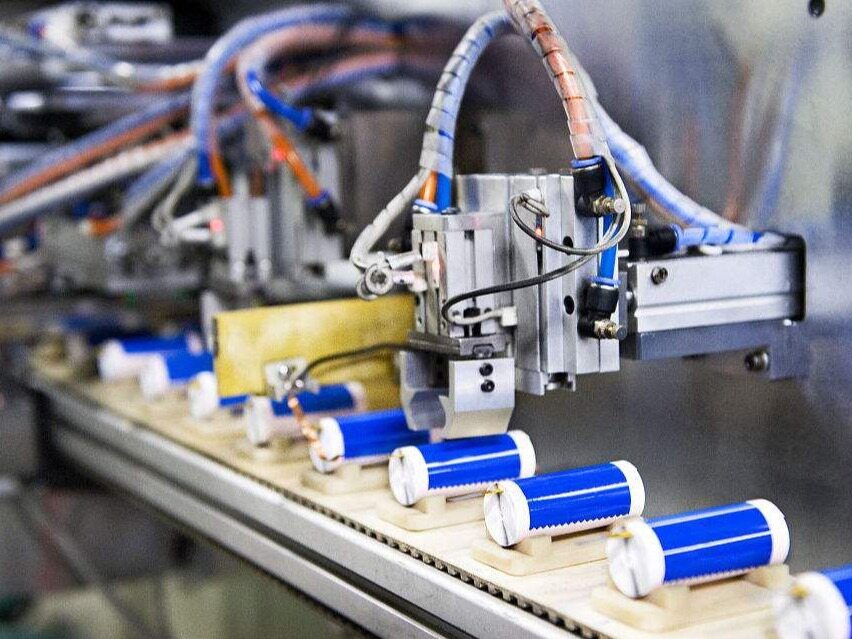

Entering the project site of Zunyi Comprehensive Bonded Zone, the pouring of retaining walls, backfilling of soil and other operations are being carried out intensively. The construction here is one of the few production lines for biochar based solid-state batteries in the world. Unlike the current mainstream lithium-ion batteries, this technological path is a material revolution that starts from the source.

The core lies in utilizing the abundant bamboo resources in Zunyi and surrounding areas to produce key battery materials from biomass materials such as bamboo powder through special processes. This innovation not only endows batteries with the green genes of "recyclability and pollution-free", but also fundamentally solves safety hazards such as leakage and fire that may exist in traditional batteries through solid-state electrolyte technology. The project investor, Guizhou Navi Sci Tech Innovation Co., Ltd., has broken through material limitations and become one of the few companies in the world that has mastered the technology, thanks to its internationally leading "plant fiber separation" technology system.

At present, the first phase of the project is in full swing, with plans to build an intelligent production line with a capacity of 4.2 GWh by the end of 2026. A grander blueprint has been drawn up: the site for the second phase project has been determined and will be launched before production, with plans to build three more production lines. At that time, a complete industrial closed loop from raw materials to high-end battery products will be formed in Guizhou. We have turned the bamboo scattered all over the mountains into safe and efficient 'energy blocks', "said the on-site engineer." This is not only a material change, but also an industrial practice of the concept of' green mountains and clear waters are as valuable as mountains of gold and silver '

Guizhou logic driven by the dual wheels of "resources+business"

Why did a cutting-edge technology project settle in the southwestern hinterland? The answer clearly points to the perfect combination of "geographical advantage" and "harmony between people". The 'geographical advantage' lies in the irreplaceable natural resources. The project leader admitted that Zunyi's abundant bamboo and aluminum resources precisely match the production needs of biochar based batteries. Bamboo powder can be used to prepare battery materials, while local aluminum ore is the main raw material for battery separators. This' local sourcing 'model has built a strong cost competitive advantage.

'Harmony' is reflected in the 'nanny style' business environment. The entire process from enterprise inspection to final decision on implementation only took two months. During this process, various complex procedures such as energy assessment, environmental impact assessment, and safety assessment were actively coordinated and handled by local relevant departments, clearing the early obstacles for the enterprise. I have been in the industry for more than 20 years and have traveled to many parts of the country. A highly efficient and proactive service team like Zunyi is indeed rare, "sighed the project manager of Guizhou Navi Science and Technology Innovation." This allows us to focus on construction and research and development without any distractions. "This efficient service is a vivid practice of Guizhou Province's development concept of" project first, service foremost ".

Leveraging the pivot of a billion dollar industry

The significance of this project goes far beyond its own output value. It is like a strategic puzzle, accurately filling the industrial gap in the field of biochar based batteries in Guizhou Province and becoming a key pivot to leverage the development of local new energy industry clusters.

Its driving effect has already emerged. In the same park, a complete vehicle manufacturing project with an annual output of 300000 new energy electric vehicles has entered the trial operation stage. In the future, locally produced solid-state batteries are expected to be directly matched with local vehicles, forming an "internal circulation" industrial chain from key components to vehicles. It is expected that after the first phase of the battery project is fully put into operation, it can achieve an annual output value of 5.7 billion yuan, contribute about 300 million yuan in tax revenue, and drive employment for more than 200 people. The Zunyi government is full of expectations for this: "This leading project is like a magnet, and we are laying out a complete upstream and downstream industrial chain around it. Its implementation has accelerated the transformation of Zunyi and even Guizhou from traditional industries to high-end manufacturing

On a deeper level, it conforms to the trend of the national energy strategy shifting westward. Recently, Guizhou Province has issued a series of policies to deepen the market-oriented reform of new energy grid connected electricity prices, aiming to create a stable and sustainable market-oriented revenue environment for new energy projects. This paves the way for the large-scale application of battery products in energy storage power stations and other fields, further expanding the market prospects of the project. Editor/Yang Beihua

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~