- The training adopts a closed-loop teaching mode of "theory practice review", allowing students to consolidate their foundation gradually

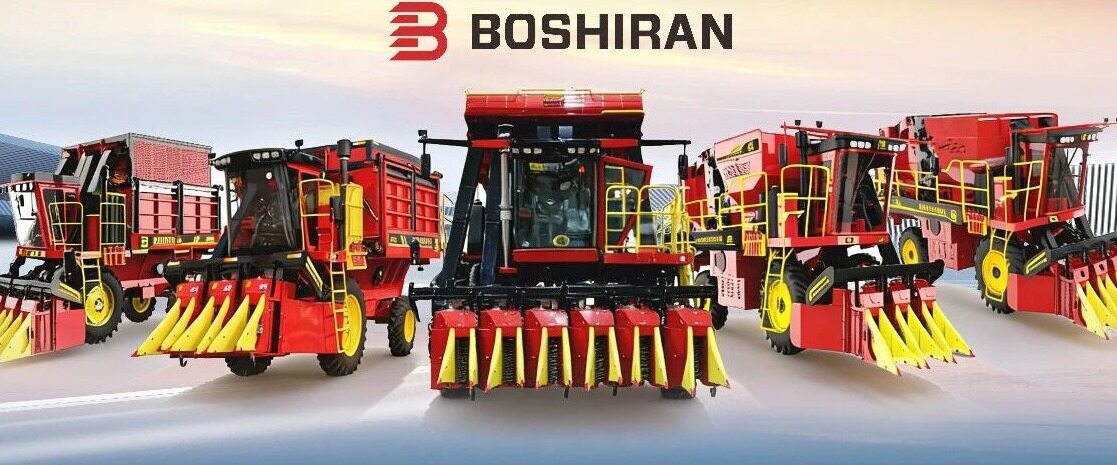

Recently, the technical backbone team of Boshiran's subsidiary in Uzbekistan successfully arrived in Xinjiang, China, embarking on a several week immersive tour of training and technical exchange. The core of this training is "theoretical foundation building, practical empowerment, and precise efficiency improvement". Through the linkage teaching of Urumqi and Wusu production bases, it builds a bridge for overseas employees to improve their technology and cultural exchange, and helps the construction of an international talent pool for enterprises and the high-quality development of overseas business.

At the Urumqi factory, the students visited the production workshop, assembly line, and R&D center, closely observing the entire process of the cotton picking machine from core component processing to complete machine assembly. They gained a direct understanding of the production process and quality control system of Boshiran.

After the visit, the students took a bus to the Wusu factory. The company held a simple yet grand welcome ceremony. The relevant person in charge of Boshiran stated at the ceremony that overseas subsidiaries are an important pivot for the global layout of enterprises. This training aims to enhance the professional capabilities of overseas teams through technology sharing and experience inheritance. In the future, we will continue to deepen cross-border talent exchanges and work together to create a win-win situation.

The training adopts a closed-loop teaching mode of "theory practice review", allowing students to consolidate their foundation and improve their skills gradually. The first stage of theoretical training focused on the core technology of cotton picking machines. The instructor systematically explained the operating principles of cotton picking machines and deeply analyzed the composition and functional characteristics of core components such as the picking head, hydraulic system, and electrical control system.

After completing the basic theoretical learning, the students walked into the after-sales workshop and, under the guidance of senior technicians, personally participated in the entire process of after-sales maintenance and upkeep of the cotton picking machine. During the intervals between practical operations, the training team organized a special review meeting, where the students shared their practical experience, sorted out the crux of the problem, and the lecturer provided targeted answers and clarifications, achieving the training effect of "practice leads to truth, review promotes improvement".

Focusing on the practical skills of cotton picking machine driving with the goal of "certified employment", high-intensity specialized training will be carried out. The training on dashboard parameter values in the early stage can be called a "feast of dry goods". The senior technicians of the agricultural service team explained in detail the normal range and adjustment skills of key parameters such as engine speed, hydraulic pressure, and net recovery rate. Combined with practical operation cases, they explained the response plan for parameter abnormalities, helping the trainees to accurately grasp the judgment method of equipment operation status.

At the driving practice site, the students were introduced to a series of difficult subjects such as reverse parking training, head lifting operation, and standardized use of indicator lights and horns. The skilled technician patiently guides each student's operational actions through a "demonstration explanation group practice one-on-one error correction" method, from driving posture, steering wheel control force, to synchronized coordination of head picking and travel speed, all of which require refinement. In response to common scenarios such as complex terrain response and sudden fault handling in overseas assignments, the training also includes simulation exercises to enhance students' emergency response capabilities in a realistic environment.

The content of this training is very practical. Whether it's practical maintenance skills or precise control of driving operations, they are all 'hard skills' that we urgently need in our overseas work, "said Kevin, an Uzbek student, during the training break.

Through the deep integration of theory and practice, the students not only systematically mastered the technical principles, maintenance and driving skills of the cotton picker, but also deeply felt the craftsmanship spirit of Boshiran's pursuit of excellence and the open and inclusive corporate culture. Many students have expressed that they will bring back the skills and experience they have learned this time to overseas positions, apply them to practical work, provide more professional technical services to local customers, and help Boshiran improve its reputation in overseas markets.

This cross-border training is an important measure for Boshiran to promote international talent cultivation, injecting technological momentum into overseas subsidiaries and enhancing mutual understanding and friendship between Chinese and foreign employees. In the future, Boshiran will continue to improve its cross-border training system, innovate teaching models, promote the sharing and inheritance of technical experience on a global scale, and contribute greater strength to the implementation of the enterprise's globalization strategy and the international promotion of agricultural mechanization technology.Editor/Bian Wenjun

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~