- In 2021, Shandong Heavy Industry Group delivered a proud report card for China Machinery Development

Orders for large-bore engines have skyrocketed, fuel cell "stuck neck" technology has accelerated breakthroughs, and Shandong's equipment manufacturing brand has been called "One Belt One Road"... After rising against the trend last year and its performance was booming, in the first quarter of this year, Shandong Heavy Industry Group once again delivered a bright Eye’s transcript-realized operating income of 164 billion yuan, total profit of 7.7 billion yuan, and industrial added value of 23 billion yuan. The fourth quarter of last year's high growth rate increased by 23.5%, 98.9%, and 29.9%, respectively, and fully realized the first quarter. A good start". The continuous rise of corporate competitiveness is like a "rolling stone uphill." Decoding the amazing "good start", Tan Xuguang, chairman of Shandong Heavy Industry Group, said that Shandong Heavy Industry resolutely follows the requirements of the provincial party committee and the provincial government to promote the conversion of new and old kinetic energy to achieve new breakthroughs, new technologies are fully empowered, and new business formats are accelerating. The rapid integration of high-end products into the domestic and international dual cycles not only achieved the high-quality start of the "14th Five-Year Plan", but also opened a new path for the province's equipment manufacturing industry to achieve technological transformation.

"Science and Technology Transformation" continues to strengthen for a long time

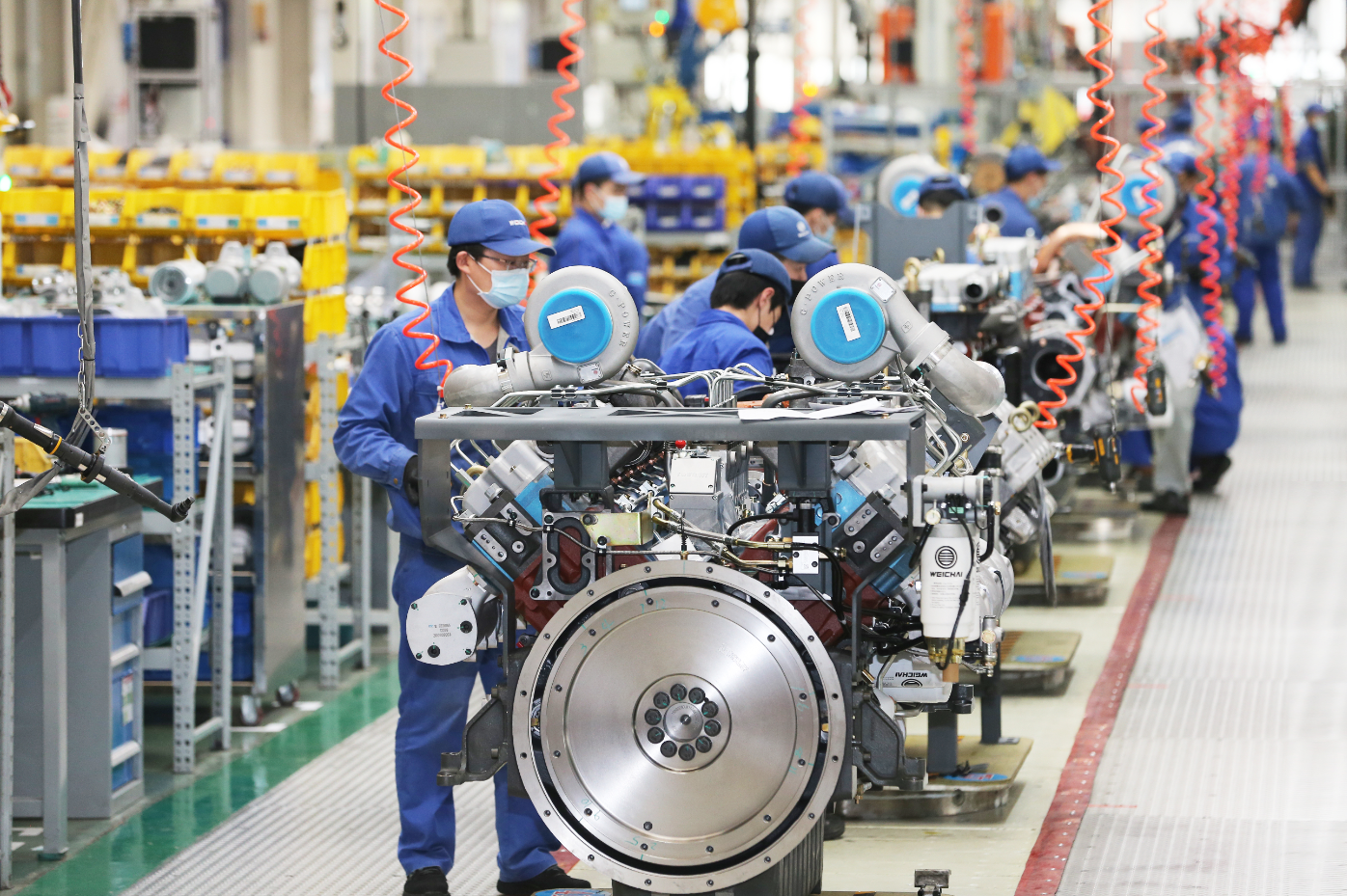

A few days ago, the first 20M33 engine with a power of 2420 kilowatts was shipped off the assembly line at Weichai Baudouin's high-speed high-end large-bore engine manufacturing base and shipped to South Korea. This is a brand-new product newly developed by Weichai, which further enriches high-speed large-bore engines. product line. Large-bore engine has high technical content, high value and high threshold. Previously, the "players" in this field were only a few international giants, and my country has long relied on imported brands in this field. Weichai, which has been "dormant" for 10 years, has now ushered in a period of surge in orders for large-bore engines, and the supply of products is in short supply. At present, a large number of urgent orders sent to Beijing, the European Union, North America, Russia, Mexico and other places are rushing to make. These in short supply will be used in backup power supply for big data centers, emergency power supply for large mines and large power station projects.

How did the time to break the game appear? "Some major core technologies must be firmly in our own hands." Weichai Power Executive CEO Zhang Quan said that Weichai actively integrates global superior resources and achieves major breakthroughs in the global large-bore engine technology field with the spirit of "a sword in ten years" , Not only has become the "preferred power" for the localization of large-bore engines for overseas brands, it has also begun to occupy a place in the international high-end power market with "competent enemies", and has been successfully sold to more than 70 countries and regions. The annual global transaction volume of this market is 50 billion US dollars, and the market potential is huge. By increasing investment in scientific and technological innovation and promoting continuous optimization of the three major structures of products, markets and businesses, Weichai has entered the "high-end cycle" where competitiveness continues to increase. "In the first quarter, Weichai's operating income increased by 67% year-on-year, total profit increased by 67% year-on-year, industrial added value increased by 79% year-on-year, and engine production and sales increased by 82.4% year-on-year." Zhang Quan said. In the face of fierce market competition, the key is to improve internal skills. Since the reform and reorganization, China National Heavy Duty Truck Group has continued to increase investment in intelligent manufacturing equipment and technological transformation. While greatly improving product quality, the production capacity of heavy trucks has increased from 750 units per day in 2019 to nearly 1,500 units at present, achieving production capacity and efficiency. The doubled increase has greatly shortened the order delivery time and laid a solid foundation for China National Heavy Duty Truck to seize the market. In the first quarter, China National Heavy Duty Truck achieved a year-on-year increase of 112% in operating income, a year-on-year increase of 138% in total profits, a year-on-year increase of 347% in total profits and taxes, and an increase of 84% in industrial added value. If the engine is compared to the "heart" of the vehicle, hydraulic pressure is equivalent to the "muscle" of the vehicle. The global high-end hydraulic technology has long been monopolized by foreign companies. Linde Hydraulics is the world leader in high-pressure hydraulic technology. After Weichai acquired it, it integrated engine + hydraulic technology resources and created the world's first commercial model of hydraulic powertrain, which not only realized the independent controllability of hydraulic technology, but also optimized the matching of control systems. , Improve product performance in an all-round way.

"Take the assembly of excavators as an example. Compared with competing products, our hydraulic powertrain has the same operating efficiency and reduced fuel consumption by 15% and noise by 2 decibels." According to Sun Guangming, deputy general manager of Linde Hydraulics (China), The proportion of localized production of technology has reached 90%. With strong technical and service network advantages, it has become the "new standard" of the current domestic excavator brand. Due to the heavy blessing of Weichai's core technology of hydraulic powertrain, the excavator business of the mountain reconstruction machine also ushered in a "warm spring". In the first quarter of this year, the sales of mountain rebuilder excavators increased by 240% year-on-year, and the growth rate significantly outperformed the industry. At present, Shandong is tightly grasping the "bull nose" of the conversion of new and old kinetic energy, with an attitude of forging ahead without waiting for time, continuing to increase strength and long-term achievements, and striding forward to the goal of "breakthrough in five years". Shandong Heavy Industry Group insists on unswervingly leading by innovation, and the "technological transformation" continues to stimulate new momentum.

The forward-looking layout of new business formats accelerates landing

Accelerating breakthroughs in core technologies is not only reflected in traditional industries, but also in the new energy business, Weichai has also received good news. It has reached a strategic cooperation with Swiss Fast Group, and the two parties established a joint venture to jointly build it into the world's leading fuel cell air compressor Provider. The fuel cell air compressor is known as the "lung" of the fuel cell power system. Its performance will directly affect the operating indicators of the fuel cell power system. It is also one of the most costly core components and a shortcoming in the development of hydrogen fuel cell engines in my country. . A strong body cannot do without strong lungs. The same is true for fuel cells. In 2018, Weichai successively cooperated with Sires of the United Kingdom and Ballard of Canada in the fields of solid oxide fuel cells and hydrogen fuel cells, and jointly developed a next-generation proton exchange membrane fuel cell stack suitable for the Chinese market with Ballard. "The stack is the'heart' of the fuel cell, and the air compressor is the'lung'. Weichai has won both, which means that China has a firm grasp of the core lifeline of the hydrogen fuel cell." General Manager of Weichai New Energy Technology Co., Ltd. Manager Zhang Chao said. At the beginning of this year, Weichai and China Automotive Technology and Research Center conducted the first domestic test of hydrogen fuel cells in cold regions. At the same time, this is the first time that hydrogen fuel cell commercial vehicles in multiple fields, such as heavy trucks, light trucks, and passenger cars, have been jointly tested in cold regions. These vehicles had a successful -34℃ low-temperature cold start, and they ran stably for a long time in a low-temperature environment spanning more than 2,000 kilometers, which attracted the attention of the entire industry.

Shandong Heavy Industry Group not only takes the lead in the field of new energy, but also takes the lead in the field of intelligent driving technology. Recently, the author came to the final assembly line of Sinotruk Jinan Truck Manufacturing Company. Workers are working overtime to assemble 29 third-generation port electric container heavy trucks ordered by Ningbo Port. These vehicles are equipped with the third-generation chassis independently developed by China National Heavy Duty Truck. They adopt battery swapping technology to avoid charging waiting time, which not only greatly improves operating efficiency, but is also economical and energy-saving, leading the new trend of port transportation. As early as 2018, Sinotruk delivered the world's first L4 unmanned electric container heavy truck, HOWO T5G, to Tianjin Port, providing efficient and intelligent solutions for port container transportation. At present, the 25 unmanned electric container heavy trucks serving Tianjin Port have a total autonomous driving mileage of more than 400,000 kilometers, creating a "Chinese model" for the intelligent upgrade of world ports.

Intelligent driving is a new trend in high-end agricultural equipment. Spring returns to the earth, it is the time when ginger is planted. In Jiang Tianli of Qu Yonggang, a villager in Qujiayan Village, Pingdu City, an unmanned tractor equipped with Weichai Lovol automatic navigation assisted driving and operation system is working in the field. The car walks in the front, and the neat and uniform ridges "rise up from the ground" in the back, without the need for human control. "Automatic navigation assisted driving and operation systems have been applied to all aspects of modern agricultural production such as farming, planting, management, and harvesting, which have greatly improved the quality and efficiency of spring ploughing and spring planting operations." said Wang Guimin, general manager of Weichai Lovol Heavy Lovol Heavy Industries uses smart agricultural machinery with precision and efficiently collaborates with Weichai in areas such as electronic control, new energy, and smart driving to accelerate the launch of high-horsepower CVT tractors. In the first quarter after the reorganization with Weichai this year, Lovol Heavy Industries released a significant amount of production capacity and increased sales. Among them, sales of agricultural equipment increased by 60% year-on-year, operating income increased by 67% year-on-year, and profit increased by 280% year-on-year. At present, the "Four New" economy represented by new technologies, new industries, new formats, and new models is growing vigorously on the land of Qilu and becoming a powerful engine for economic growth. The key to developing the "four new" economy depends on the ability to transform scientific and technological achievements. Shandong Heavy Industry Group actively promotes the implementation of new business models such as fuel cells and intelligent driving, successfully transforms "technological advantages" into "industrialization advantages", and builds a "second moat" for the rapid growth of enterprises, which has accumulated new opportunities for seizing new outlets in the industry. power.

Hard core strength seizes the opportunity of "carbon peak"

"'Carbon peaking' is a commitment made by the Chinese government to the world. Enterprises do not have the problem of bargaining. In particular, industry leading enterprises like Weichai should have the responsibility. This will also force the internal combustion engine industry to save energy and reduce emissions. Upgrade of key core technologies, contribute to society’s energy saving and emission reduction, and give play to our strong technological leadership in the global industry.” This is Tan Xuguang’s comments on investors’ comments on “Carbon Peak” at Weichai Power’s 2020 annual results conference. "Reply to the question.

Where does Tan Xuguang's confidence come from?

On February 4 this year, under the supervision of the national environmental protection authority, Weichai's WP2.3NG non-road engine completed all test items and obtained the industry's first environmental information disclosure list since the release of the National Fourth Standard for non-road mobile machinery. Coincidentally. On October 9, 2018, Weichai received the Environmental Information Disclosure List issued by the Ministry of Ecology and Environment under the number 000001. Weichai WP4.6N engine was the first to pass the National VI B official certification for heavy-duty diesel engines. "Weichai’s “Double First” emission certifications for national six and non-road national four are obvious to all. Weichai is not only an active promoter of the upgrading of China’s emission regulations, but also a practitioner."

Thanks to a 10-year high-level R&D investment of 30 billion yuan, Weichai has completed the development of a full series of road country VI and non-road phase IV products ahead of schedule. Cheng Guangxu, vice president of Weichai Power, who is in charge of market sales, told the author that, due to the timely delivery of products, Weichai seized the first opportunity of the National VI. By the end of last year, it had accumulated more than 200,000 National VI engines, leading the industry. In the first quarter of this year, sales of Weichai's National VI engines increased by 191% year-on-year, and the momentum remains strong. From July 1, 2021, the national VI emission standards for heavy-duty diesel vehicles will be fully implemented; from December 1, 2022, the fourth phase of the non-road mobile machinery standards will be officially implemented. The upgrade of emission regulations has brought a strong shock wave to the industry. From the technology upgrade of the engine to the system matching of the whole vehicle, a new wave of upgrades will surely be set off.

In January this year, children in Pukou District, Nanjing welcomed a group of "new partners", and 47 Taichung Tongguo Six School Buses were officially put into use. For more than two months, the Zhongtong school bus has won praises from parents and children for its safety, comfort and intelligence. "In the National VI era, we are not only pursuing emission standards and compliance, but through technological upgrades to achieve a leap in the quality of new products, and continue to lead the high-end upgrade of Chinese buses with higher added value and better customer experience. "Zhongtong Bus General Manager Peng Feng said. In the first quarter, Zhongtong Bus focused on the high-end market segment, seized the opportunity to attack quickly, and achieved a good start in the fields of brigade buses and school buses. In particular, in conjunction with Weichai Power’s technical advantages, Zhongtong Bus has launched nucleic acid detection vehicles, mobile CT vehicles, and negative pressure ambulances. With high-end technical quality and humanized product design, it has made important contributions to the fight against the epidemic. .

AMT gearboxes are currently a new trend for high-end heavy trucks, and they "have a lot to do" in reducing vehicle emissions and saving fuel. At present, the fifth-generation S-AMT 16-speed gearbox independently developed by China National Heavy Duty Truck has reached the world-class level, with low fuel consumption, fast response and smooth shifting. Under the same circumstances, the shifting speed is 0.75 seconds higher than similar products. Compared with manual gearboxes, heavy trucks equipped with S-AMT 16-speed gearboxes can save 2 liters of fuel per 100 kilometers, and can save more than 20,000 yuan in fuel consumption by running 200,000 kilometers a year.

"Carbon Peak" and "Carbon Neutrality" will surely restructure the energy industry and manufacturing industry. As the world's second largest carbon emission source, the transportation industry has an important impact on my country's achievement of the "Carbon Peak" and "Carbon Neutrality" goals . Shandong Heavy Industry Group takes the opportunity of emission upgrade to comprehensively upgrade its technical level, products and services, and face the challenges and opportunities brought by "carbon peak" and "carbon neutrality", which not only demonstrates the strength of hard core technology, but also demonstrates the responsibility of large state-owned enterprises And responsible.

In the "Belt and Road", famous for Shandong manufacturing brand

In March this year, more than 100 sets of Shantui complete sets of equipment "assembled" Qingdao Port, which was spectacular. These products travel across the oceans to key countries along the “Belt and Road” to help local infrastructure construction. "The total value of this batch of complete sets of equipment is more than 65 million yuan, covering bulldozers, loaders, road rollers, graders and other products and accessories, and will provide customers with a full set of engineering construction equipment solutions." According to relevant business personnel of Shantui Co., Ltd., affected by the epidemic As a result, companies continue to explore new sales models, decisively adjust the layout of overseas channels, and take market demand as the guide to enhance market competitiveness through measures such as product line supplements, product enhancements and quality improvements. Taking this shipment as an example, Shantui took the initiative to explore a new route for liner, took full advantage of Shandong port, adopted roll-on liner centralized shipping equipment, and reached the port of destination country directly, realizing "door-door" linear transportation from factory to customer. Reduced logistics costs, improved transportation efficiency, and effectively alleviated the plight of insufficient capacity caused by the epidemic.

The European market is the focus of Weichai Lovol. Recently, with the successful signing of orders for 423 tractors, Weichai Lovol's overseas marketing company Europe region ordered more than 2,100 units in the first quarter, exceeding the budget target. The 2021 epidemic has exacerbated the imbalance in global logistics. European agricultural machinery companies generally under-operate and their product delivery capabilities have declined. Weichai Lovol has seized market opportunities and has achieved full gains by unifying product resources, optimizing channel networks, and introducing flexible pricing strategies. In Russia's Mullum Power Plant Phase I project, with its excellent performance, Weichai Power Plant's overall solution won the trust of local customers. The customer immediately launched the Phase II project and designated to purchase Weichai products and services. Strengthening the advantages of the full range of products, Weichai’s export business performed very well in the first quarter, achieving an export value of 110 million U.S. dollars, a year-on-year increase of 65%. Among them, the monthly export volume of engines in March exceeded 3,000 units, with an export value of 48 million U.S. dollars. The monthly export performance reached a record high.

During the Lantern Festival this year, 300 Haohan E7 tractors were loaded and sent to Nigeria one after another on the terminal of Tianjin Port. This is the result of the efforts of Sinotruk's marketing team in Nigeria to give up the Spring Festival to reunite with their families. China National Heavy Duty Truck is the export benchmark of the heavy truck industry, ranking first in the industry for 16 consecutive years, and its export volume accounts for half of China's heavy truck exports. Overcoming the adverse effects of the overseas epidemic, China National Heavy Duty Truck also delivered a report card of "contrarian growth" in the first quarter-20,300 new vehicle export orders, a year-on-year increase of 98%.

Based on the domestic cycle and actively integrated into the domestic and international dual cycles, Shandong Heavy Industry Group has rapidly entered the global market through the forward-looking layout of high-end products, and has made a name for the Shandong equipment manufacturing brand and polished the Chinese brand in the "Belt and Road".Editor/Xing Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~