- China makes major technological breakthroughs in the field of urban deep underground space development

On the morning of June 18, a milestone was achieved at the Hongxin Drainage Pump Station Initial Rainwater Storage Gallery Project in Shanghai—China's first domestically developed large-diameter shaft boring machine was successfully launched. This signifies the official commencement of core construction for China's first mechanically constructed shaft-type initial rainwater storage gallery, representing a major technological breakthrough in deep urban underground space development.

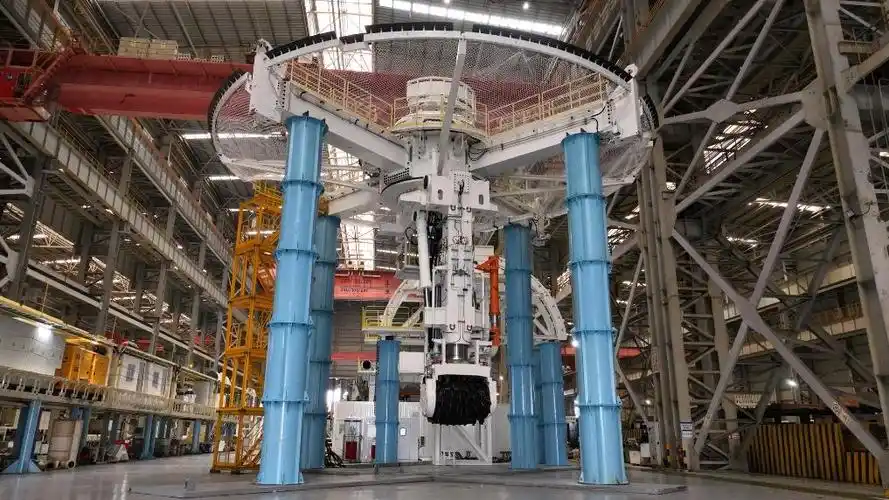

Located in Qibao Town, Minhang District, Shanghai, the project features a circular shaft with a diameter of 16.3 meters and a depth of 44.6 meters, equivalent to building a 15-story "rainwater bank" underground. To overcome three world-class challenges—ultra-large cross-section excavation, high-precision segment assembly, and ultra-deep vertical shaft control—China Railway 11th Bureau Group and China Railway Construction Heavy Industry jointly developed this 522-ton, 1,400-kilowatt "national treasure" after 18 months of research.

The boring machine integrates multiple innovative technologies:

Intelligent Deviation Correction System: Laser gyroscopes enable real-time monitoring, keeping vertical deviation within 1/1000.

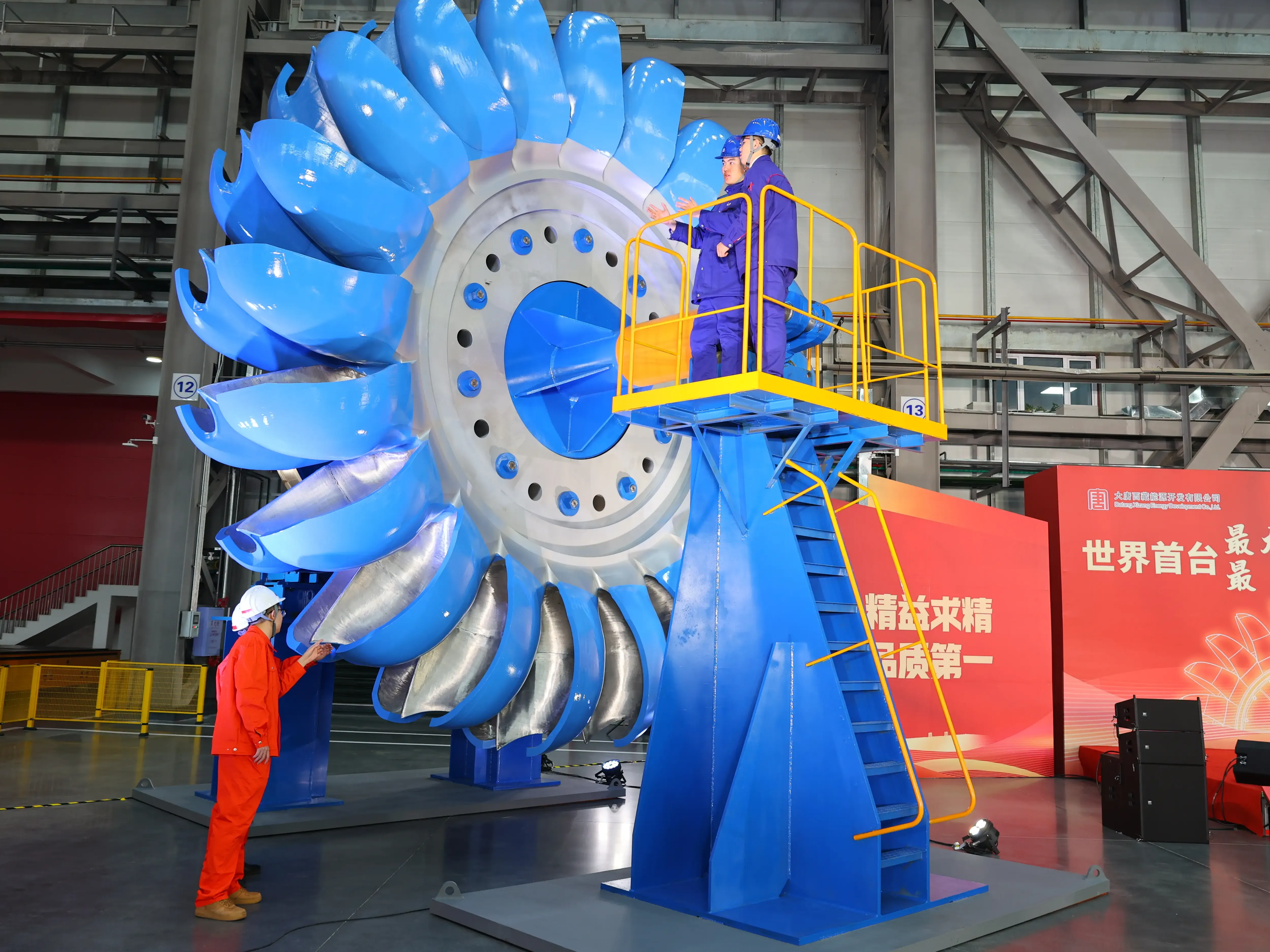

Modular Cutterhead Design: Equipped with 87 customized disc cutters for complex geological conditions.

Cloud-Based Monitoring Platform: Allows remote real-time adjustment of construction parameters.

Green Construction Technology: Noise levels below 65 decibels and 70% less dust compared to traditional methods.

Upon completion, the underground storage space will hold 30,000 cubic meters of initial rainwater runoff, effectively addressing flooding across approximately 5 square kilometers in Qibao and benefiting over 200,000 residents. The innovative "shaft + gallery" design saves 60% of land compared to traditional horizontal galleries, setting a new paradigm for water management in densely populated megacities.

A project leader from Shanghai Municipal Engineering Design Institute stated that this technology not only breaks developed countries' monopoly in deep shaft construction but also establishes replicable Chinese standards. It is expected to be applied in other Yangtze River Delta cities for utility tunnels and deep drainage systems, reducing costs by 15–20% and shortening construction periods by about 30%.(This article is from the official website of Seetao www.seetao.com. Reprinting without permission is strictly prohibited. Please indicate Seetao.com + original link when reprinting) Seetao.com Strategy Column Editor/Sun Fengjuan

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~