- China has successfully developed the world's largest 500 MW percussion turbine runner, setting a new world record

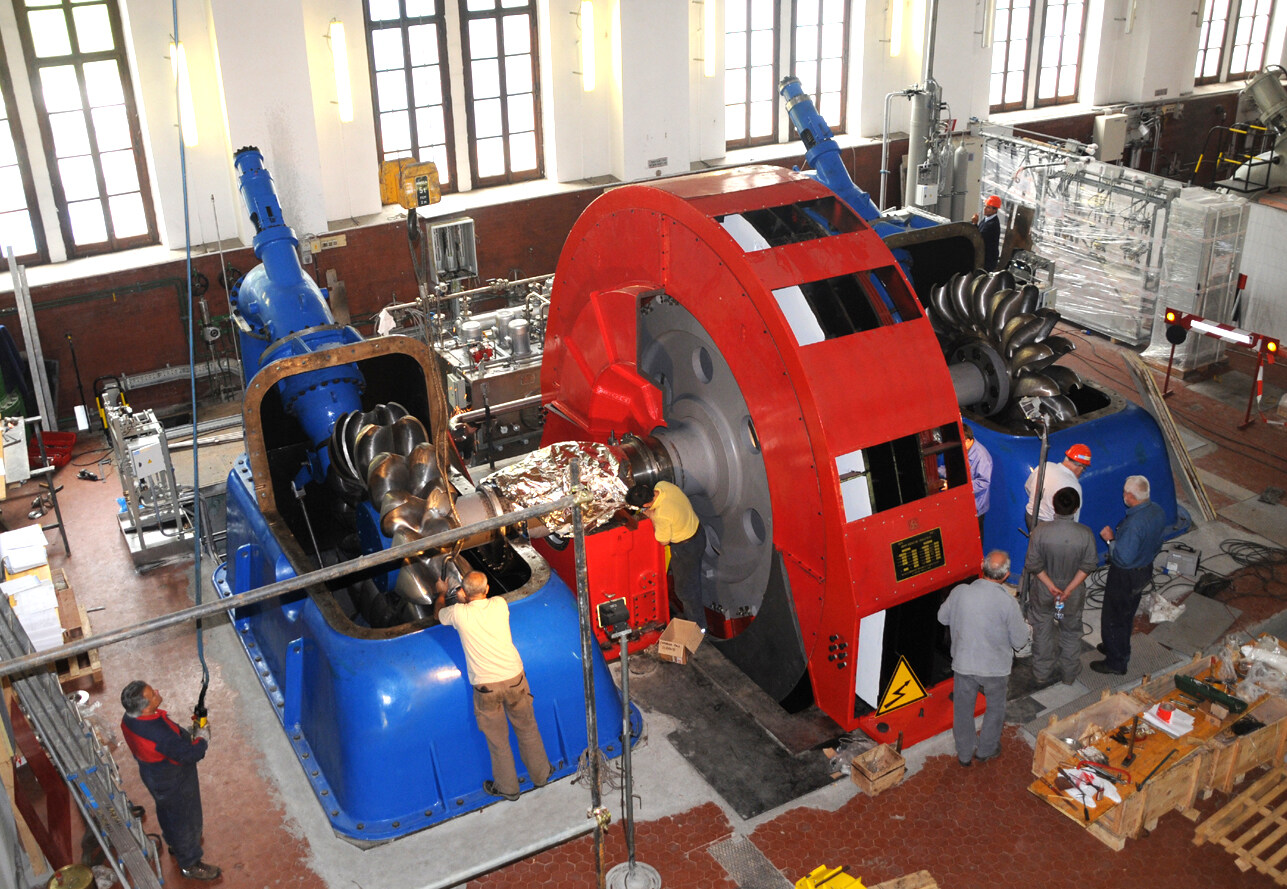

On July 2, 2025, the world's first single-machine impact turbine core component, with a maximum capacity of 500 megawatts and a diameter of 6.23 meters, independently developed by Harbin Electric Power Group Harbin Electric Machinery Factory Co., Ltd., was successfully shipped. This major achievement marks my country's historic leap from "following" to "leading" in the field of core equipment of high-head and large-capacity impact turbine units, and sets a new benchmark for the world's hydropower equipment technology.

Conquer the hydropower and Mount Everest to create super equipment

The wheel shipped this time will be used in the Zalah Hydropower Station in Tibet, which is the backbone project of the country's "Tibetan Power Transmission" and is also the most difficult impact hydropower project under construction in the world. The power station adopts two 500 megawatt impact units with the largest single-unit capacity and the highest technical difficulty in the world, and is listed as the first major technical equipment project in the energy field of the National Energy Administration.

The water bucket rotor of the impact turbine can be called the "heart" of the unit and plays the key role of converting water flow energy into mechanical energy. The Zara rotor has reached the industry limit in terms of structural parameters, hydraulic performance and manufacturing processes. Its single-unit capacity has been increased by nearly 3 times compared to conventional impact units. The diameter of the rotor has exceeded the 6-meter mark and can withstand huge impact forces of water heads over 1,000 meters. The R&D team has innovatively adopted high-strength stainless steel overall casting technology to increase the hydraulic efficiency of the rotor to more than 92% while ensuring structural strength.

Break through technical barriers and lead industry development

The development of this rotor has overcome many world-class problems:

Material Innovation: Developed a new martensitic stainless steel material with high strength and cavitation resistance;

Process breakthrough: The first composite manufacturing process of "five-axis linked CNC machining and robot precision welding" is to control the processing accuracy to within 0.05 mm;

Test and verification: The world's first 500-megawatt impact wheel test platform was built, and 2,000-hour limit working condition simulation was completed.

Zhang Chaoran, an academician of the Chinese Academy of Engineering, pointed out: "This is not only a breakthrough in single-unit capacity, but also a new era for the application of impact units in giant hydropower stations." Compared with traditional mixed-flow units, this technology can improve the power generation efficiency of high-head power stations by 15%, and reduce carbon dioxide emissions by about 2 million tons throughout the life cycle.

Serving national strategies empowering clean energy

After the completion of the Zala Hydropower Station, the annual power generation will reach 4.5 billion kilowatt-hours, which is equivalent to saving 1.4 million tons of standard coal. The successful application of this rotor will promote my country to master the core technology of ultra-high water head hydropower stations above 700 meters, and provide key equipment support for the construction of the integrated base of "water, wind, light and storage" in southeast Tibet. The general manager of Harbin Electric Power Group said that this breakthrough has enabled my country to provide full equipment for more than 90% of the world's hydropower stations, and it can drive the industrial chain value of more than 20 billion yuan in the future.

With the acceleration of global energy transformation, this technological breakthrough not only strengthens my country's voice in the field of high-end hydropower equipment, but also provides Chinese solutions for hydropower development in countries along the Belt and Road, helping to achieve the goal of carbon peak and carbon neutrality. Industry experts believe that this achievement marks that my country has fully mastered the "crown jewel" in the field of hydropower equipment and is leading the world's hydropower into the "super impact" era.(This article is from the official website of Seetao www.seetao.com. Reprinting without permission is strictly prohibited. Please indicate Seetao.com + original link when reprinting) Seetao.com Strategy Column Editor/Sun Fengjuan

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~