- After the project is completed, it will produce 2.005 billion standard cubic meters of synthetic natural gas annually

- The project runs through the concept of "innovation driven" throughout, using a combination of crushed coal pressurized gasification and pulverized coal pressurized gasification processes

In the vast Gobi Desert of Xiheshan Community in Zhundong Development Zone, Xinjiang, there used to be only the silence of the wind sweeping over the mineral veins. Now, with the official approval of the National Energy Group's 16.096 billion yuan coal to natural gas project, a modern coal chemical industry new city is about to emerge on this land that carries the endowment of coal resources - giant tower cranes will gradually enter the site, pipeline networks will extend vertically and horizontally, and the industrial miracle of "Wujin" turning into "green energy" is moving from blueprint to reality. This is not only the landing of a billion dollar investment, but also a vivid footnote to the transformation of China's coal chemical industry from "scale expansion" to "high-end low-carbon".

Strategic coordinates for anchoring coal to natural gas production

As another heavyweight layout of the national energy group in the coal chemical industry, the finalization of this project is not accidental. Behind the total investment of over 16 billion yuan is a precise grasp of energy security strategy and industrial upgrading needs. The project is located in the Zhundong Development Zone, adjacent to a coal base with abundant reserves. It can convert 16.12 million tons of raw coal on-site every year, solving the distance and cost problems of "transporting coal from Xinjiang" from the source and achieving efficient connection between resource development and on-site conversion.

According to the plan, the project will produce 2.005 billion standard cubic meters of synthetic natural gas annually after completion, including 119000 tons of liquefied natural gas. At the same time, various high value-added products such as crude phenol and coal tar will be produced as by-products, forming an industrial pattern of "stable supply of main products and diversified value-added of by-products". This layout not only fills the gap in regional clean energy supply, but also enhances the project's ability to resist market risks through product diversification, becoming an important pillar of the national energy group's "coal based, multi energy complementary" industrial system.

Independent innovation supports the green transformation framework

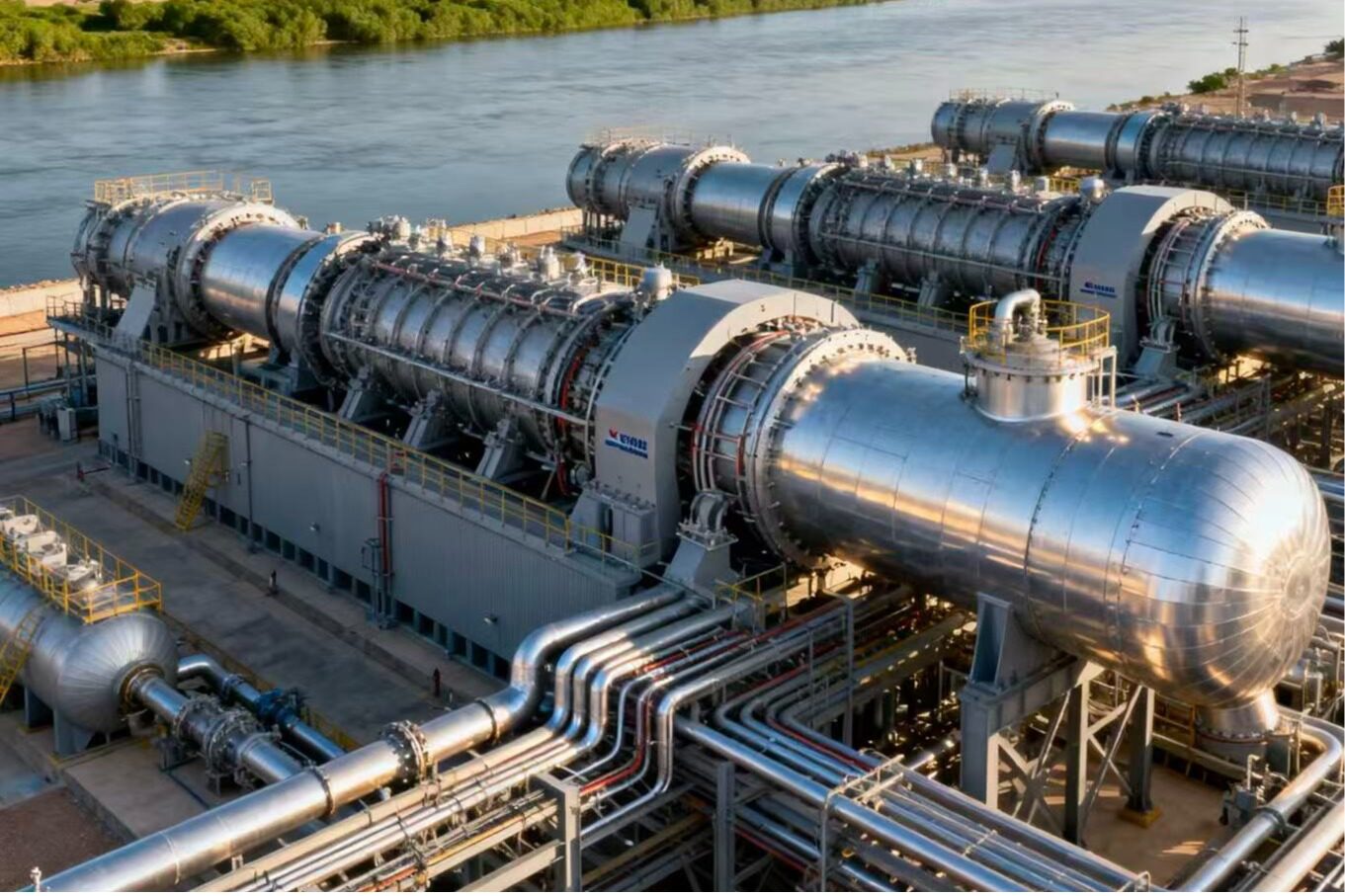

The high-quality development of the coal chemical industry relies on the independent and controllable technology, as well as green and low-carbon practices. The project runs through the concept of "innovation driven" throughout, adopting a combination of crushed coal pressurized gasification and pulverized coal pressurized gasification processes, and fully applying mature and advanced domestic technologies in key processes such as gasification, transformation, and purification. This not only ensures the reliability of the project, but also promotes the localization iteration of core technologies.

In terms of low-carbon transformation, the project deeply integrates the mature experience of the National Energy Group in the CCUS (Carbon Capture, Utilization, and Storage) field, synchronously plans supporting low-carbon emission reduction facilities, and efficiently captures and utilizes the carbon dioxide generated in the production process, achieving a closed-loop operation of "production emission reduction cycle". This dual wheel drive model of "technology+environmental protection" not only greatly improves the efficiency of coal conversion, but also brings the carbon emission intensity of the project to the advanced level in the industry, perfectly interpreting the development concept of "coal is not a backward energy source, what is backward is the utilization method".

Refactoring the Value Creation Logic of Coal Chemical Industry

If the traditional coal chemical industry is a single mode of "eating coal and selling raw materials", the project of National Energy Group has built a full chain value system of "resources - products - by-products - reuse". In addition to the core natural gas products, the by-products such as crude phenols and naphtha produced by the project will become high-quality raw materials for downstream fine chemical and new materials industries, promoting the formation of an industrial cluster effect of "coal gas chemical materials".

This chain extension approach is the core logic of the coal chemical transformation of the National Energy Group. From the coal based aerospace kerosene assisted rocket maiden flight of Ordos Coal to Oil Company, to the world's first coal to biodegradable material project of Yulin Chemical, and now to the layout of coal to natural gas, the group has formed a diversified product matrix of "oil chemical new materials", upgrading coal from an industrial "grain" to a high value-added "refined grain". The more than 14000 job opportunities brought by the project, as well as its driving effect on upstream and downstream industries, will inject lasting momentum into the local economy, achieving a win-win situation for industrial development and improvement of people's livelihoods.Editor/Bian Wenjun

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~