- This certification demonstrates the product competitiveness of Extreme Electric Energy in offshore photovoltaics

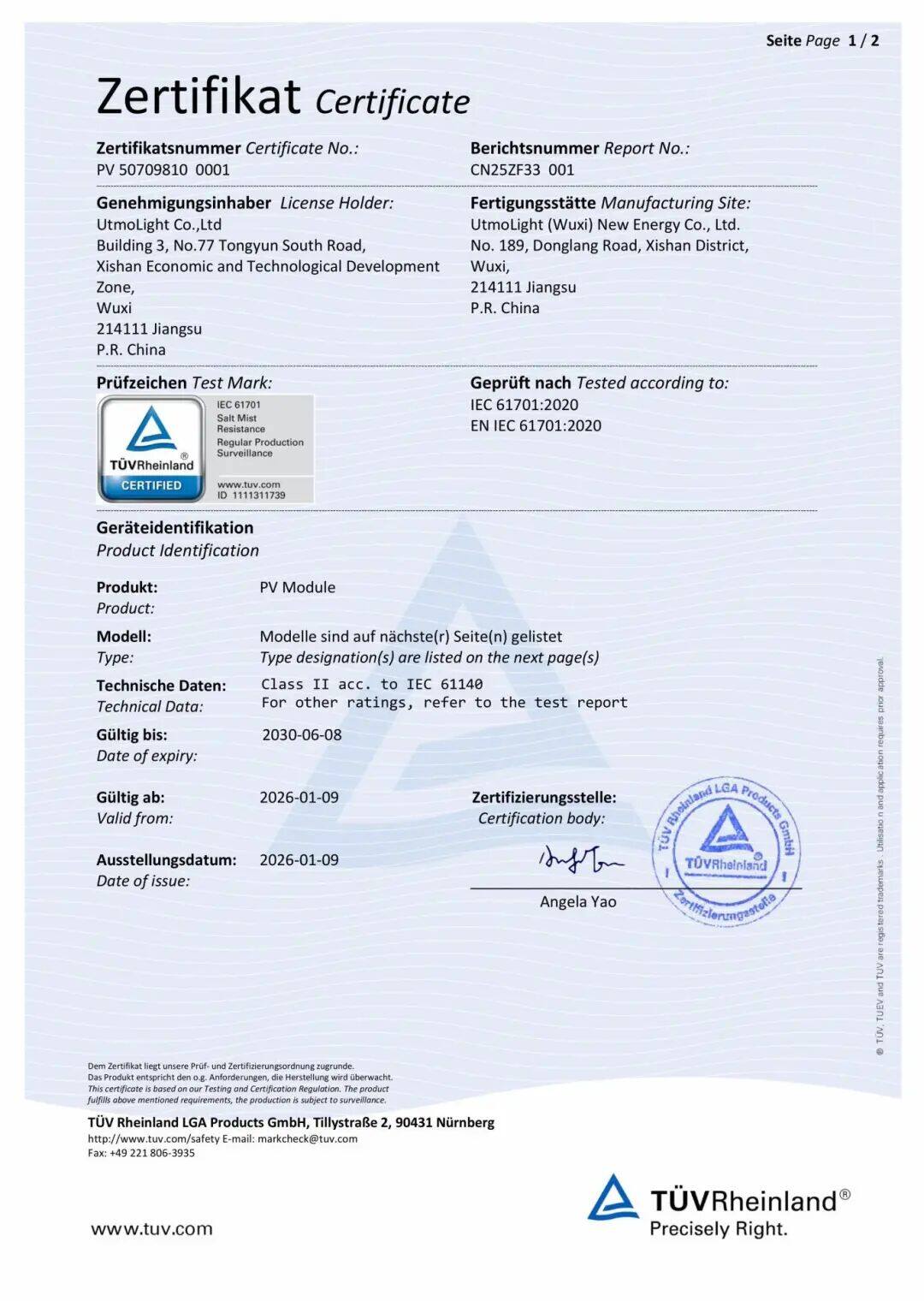

On January 15, 2026, Utmolight once again reached a milestone moment: the globally authoritative testing organization T Ü V Rheinland awarded Utmolight the world's first perovskite component salt spray testing certification certificate. This is not only an authoritative recognition of the reliability of Utmolight products, but also marks the initial product strength of perovskite photovoltaic technology to enter the offshore photovoltaic market, and an important leap in technological value. Utmolight has also become the world's first enterprise in the perovskite field to pass this certification.

Dr. Gao Qi, Chief Technical Expert of Solar Energy and Commercial Product Services for T Ü V Rheinland Greater China, Dr. Zhou Xuewei, Deputy General Manager of Solar Energy and Commercial Product Services for Greater China, Dr. Zheng Ce, Executive Vice President of Utmolight, Dr. Shao Jun, CTO, and other leaders and guests attended the certification ceremony.

In recent years, with the sustained economic development and increasing demand for electricity in coastal areas, power and land resources have become increasingly scarce, giving rise to the concept of "offshore photovoltaics". It can not only efficiently utilize vast sea resources and alleviate land pressure, but also has the potential to increase power generation, and is expected to play a key role in the future new energy system. However, harsh conditions such as high salt spray, high humidity, and strong winds and waves in the marine environment also place extremely high demands on the long-term reliability of photovoltaic modules.

The certified product this time is a 2.81 ㎡ perovskite photovoltaic module, produced on the GW level production line of Jidian Solar Energy. It adopts multiple innovative protective designs, including the addition of anti-corrosion and anti reflective film layers on FTO glass, upgrading the anti-corrosion of component edge sealing, junction boxes, and frames, enhancing structural durability, etc., which can fully meet the power generation needs of special salt spray corrosion environments such as offshore photovoltaics. Relying on superior product design, in T Ü V Rheinland's professional and rigorous salt spray testing, the 2.81 ㎡ perovskite photovoltaic module of Jidian Solar successfully passed the IEC 61701:2020 standard salt spray 7 test certification, demonstrating excellent product tolerance and stability.

As a global leader in the commercialization of calcium titanium minerals, Utmolight has always adhered to a market strategy of "customer-centric and scenario oriented", safeguarding customer value with reliable quality. Previously, the 2.81 ㎡ perovskite module of Jidian has passed the T Ü V Rheinland IEC 61215 and IEC 61730 full sequence testing certification, covering multiple rigorous projects such as wet freezing, thermal cycling, wet heat, UV, mechanical load, etc. It will be put into operation in multiple empirical bases across the country from 2025, accumulating a large amount of key data in terms of power generation efficiency, corrosion resistance, wind and wave resistance, and even under the invasion of super typhoons such as "bamboo grass", it still maintains structural integrity and stable operation, demonstrating excellent environmental adaptability and reliability.

The passing of the salt spray test certification further expands the application scenarios of perovskite modules, highlighting Utmolight's product competitiveness in the emerging market of offshore photovoltaics. It will play a key role in promoting the development of perovskite technology and its large-scale commercial applications in multidimensional scenarios.

In the future, Utmolight will continue to deepen its innovation in perovskite tower technology, improve its product layout, and be committed to providing global customers with higher value and more reliable perovskite photovoltaic solutions. It will fully respond to the diversified needs of energy transformation and contribute greatly to building a clean, low-carbon, safe, and efficient energy future.Editor/Yang Meiling

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~