- Multi departmental collaboration to promote deep integration of artificial intelligence and manufacturing industry

On January 27, 2026, the "Implementation Opinions on the Special Action of Artificial Intelligence+Manufacturing" jointly issued by the Ministry of Industry and Information Technology and eight other departments was officially announced, marking the "fast forward button" for the intelligent transformation of China's manufacturing industry. Against the backdrop of the global wave of artificial intelligence, this document not only outlines a clear roadmap for industrial upgrading, but also demonstrates through a series of specific cases how AI can reshape the competitiveness of "Made in China" from production workshops to supply chain ecosystems. From Sany Heavy Industry's intelligent factory to Haier's customized platform, a profound transformation driven by technology and fueled by data is quietly happening in every corner of the manufacturing industry.

Top level design accelerates the integration process

The issuance of the Implementation Opinions on the Special Action of Artificial Intelligence+Manufacturing is a key measure for promoting the deep integration of AI and manufacturing at the national level. This document clarifies various goals such as technological breakthroughs, scenario expansion, and ecological cultivation, aiming to systematically solve the core problems faced in transformation, such as "not being able to transform, not being able to transform, and not daring to transform". Among them, in response to the common pain points faced by small and medium-sized enterprises such as high computing power costs and high technological barriers, the policy specifically encourages the provision of precise subsidies through the issuance of "computing vouchers" and supports the development of lightweight and easy to deploy AI tools, aiming to lower the threshold for transformation, make intelligent red benefits and a wider range of enterprise entities, and promote the expansion of AI applications from "demonstration points" for large enterprises to "scenic spots" for the entire industry.

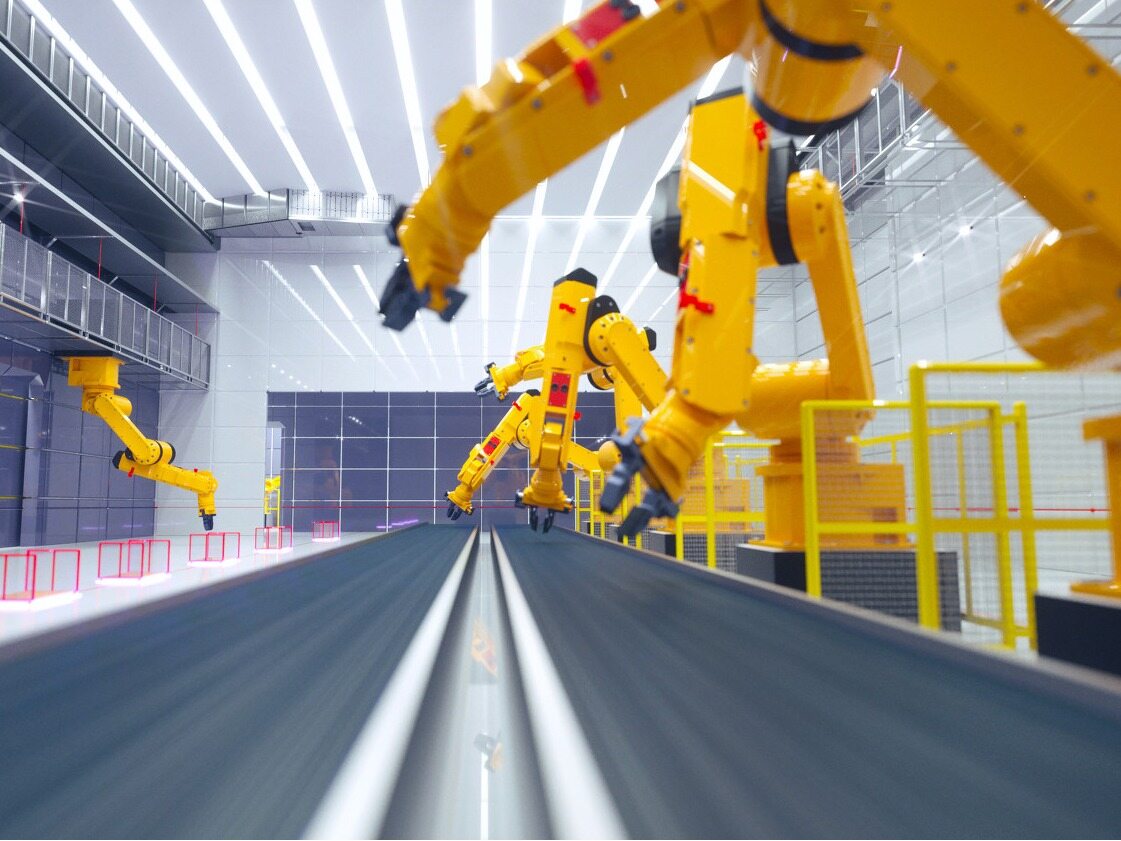

AI driven production mode transformation

Driven by policy guidance and market demand, artificial intelligence technology is deeply integrated into the core manufacturing process, driving fundamental changes in production efficiency and patterns. Leading enterprises have taken the lead in exploring: Sany Heavy Industry has replaced traditional manual inspection and production scheduling by introducing AI visual inspection and intelligent scheduling systems. While improving detection accuracy and reducing error rates, it has also achieved flexible production of multi category engineering machinery, enabling production lines to adapt flexibly to market fluctuations. The Haier Kaos platform utilizes AI algorithms to connect the entire chain of design, manufacturing, and operation data, promoting the transformation of production mode from large-scale batch manufacturing to personalized on-demand customization, significantly improving resource utilization efficiency and product market matching. These practices indicate that AI is driving the manufacturing industry from relying on experience based decision-making to data-driven intelligent regulation. Keywords: New Infrastructure News, New Infrastructure Information Network

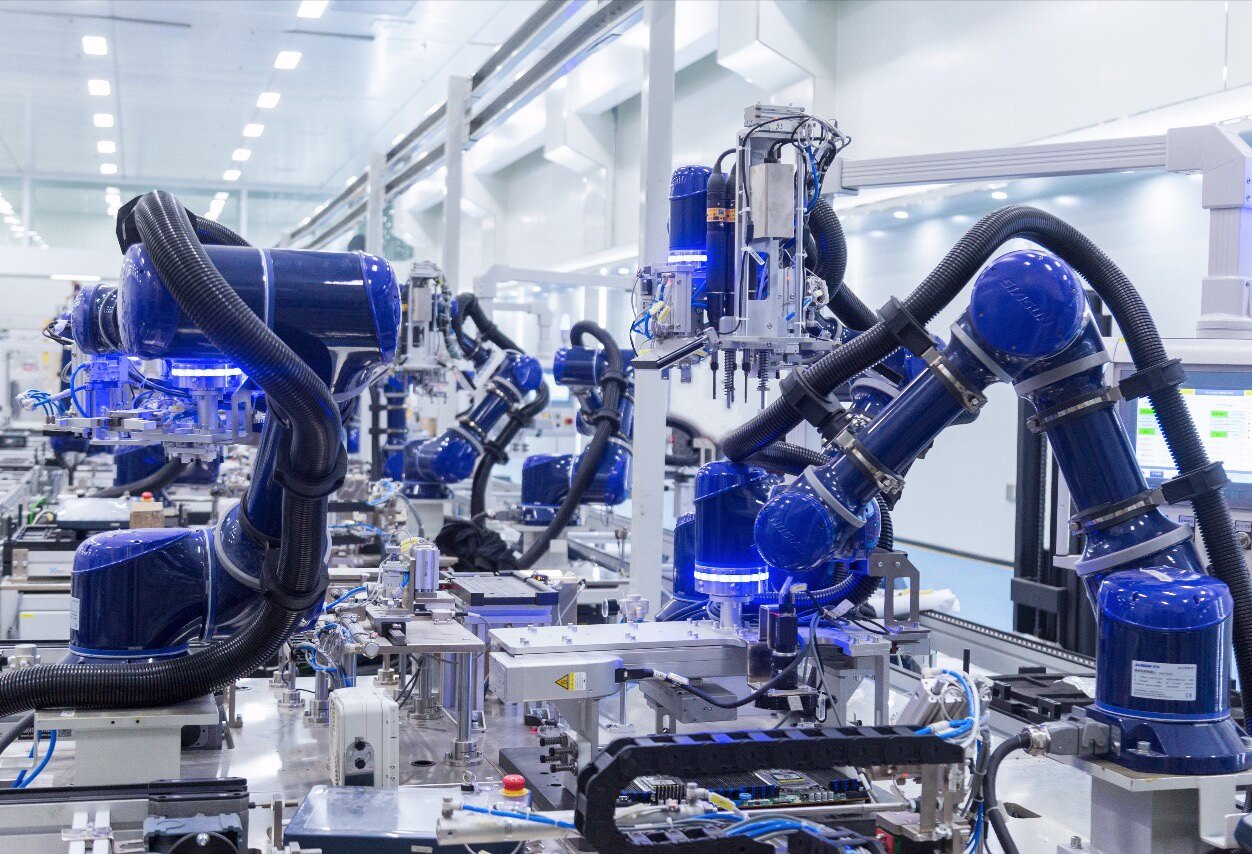

Collaborative empowerment of industry wide upgrading

The deep integration of artificial intelligence and manufacturing industry is far beyond the technological transformation of individual factories or enterprises, and relies more on the construction of a collaborative and open industrial ecosystem. On the one hand, platform based enterprises such as Haizhi Online have effectively solved the long-standing supply and demand docking problems in non-standard parts and other fields by building an AI driven supply chain collaboration platform and utilizing intelligent matching and scheduling functions, achieving efficient and accurate linking of global orders and domestic manufacturing resources. On the other hand, chain owners such as Shanghai Steam Turbine Factory have used their own digital transformation as an opportunity to reconstruct production processes through technologies such as AI digital twins, and have driven upstream and downstream suppliers to achieve data interoperability and standard collaboration, forming a new cluster development model of "technology leadership, platform empowerment, and industry linkage". This ecological upgrade from single point breakthrough to global collaboration has laid a solid foundation for the overall competitiveness of the manufacturing industry.Editor/Gao Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~