- The scale of Shanghai Jintai's single anchor is also sufficient to be listed as a milestone in China's bridge foundation

In 30 days, 102 equal-thickness mixing walls were efficiently completed, and the advantages of the SMC construction method were again verified

At 1pm on April 13, 2020, news came from the southern anchorage foundation construction site of the Nanjing Xianxin River Crossing Channel: the southern anchorage foundation reinforced by the Shanghai Jintai SC55 hydraulic milling and stirring rig drilled the 102nd mixing wall smoothly. Since the start of construction on March 13, 2020, the SC55 has been highly efficient, reliable, and stable. It exceeded expectations by nearly 70% in one month. It is expected that 155 pieces of 45-48 meters deep, 700mm and other thick mixing walls will be completed in advance at the end of this month, and the advantages of the SMC construction method will be verified again.

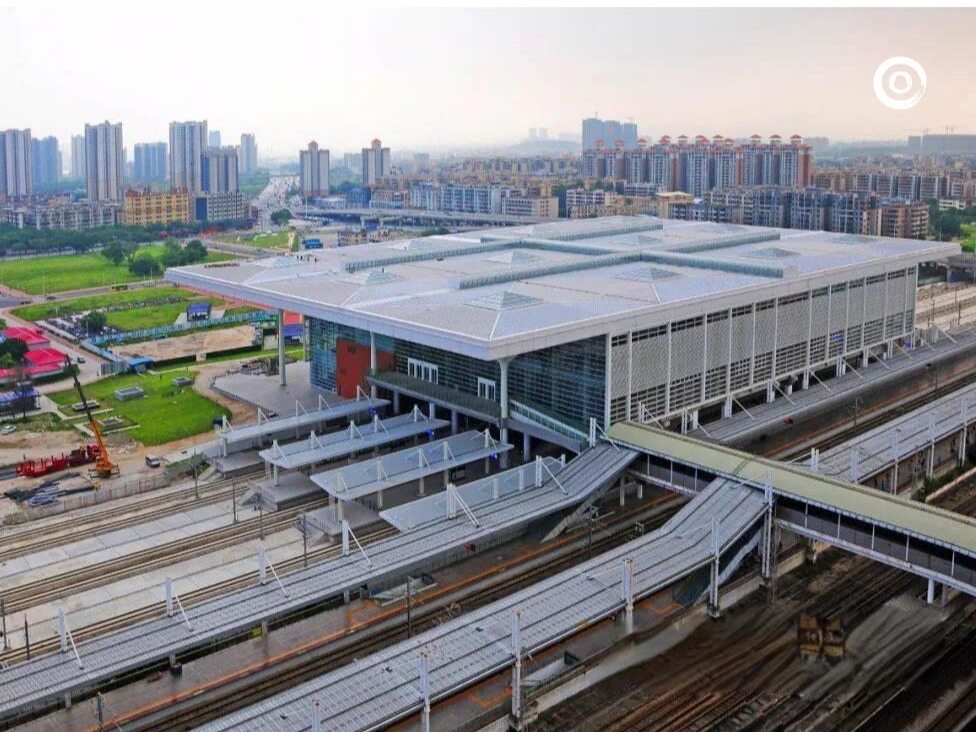

The 65-meter outer diameter and 57-meter excavation depth are enough to be listed as a "milestone" of China's bridge foundation

The Nanjing Xianxin Road River Crossing Project is a major urban development project of the “13th Five-Year Plan” in Jiangsu Province, with a total length of about 13.17 kilometers, of which the cross-river bridge is a single-span suspension bridge with a main span of 1760 meters. This span is among the same bridge types. The first in the country and the second in the world (the Japanese Akashi Strait Bridge completed in 1998 with a single span of 1991 meters is currently the largest single-span suspension bridge in the world). The South Bank Anchorage Project was constructed by the Fourth Company of the Second Aviation Administration of China Communications. It uses a pure circular ground connection wall foundation. The anchorage has an outer diameter of 65 meters and an excavation depth of 57 meters. This single anchorage is also large enough to be listed on the Chinese bridge foundation. "Milestone".

The SMC construction method was first applied to the reinforcement of the foundation wall of bridge anchorage

In view of the geological characteristics of ultra-thick soft soil and uneven coverage in the project site, the foundation around the trench wall of the ground connection wall needs to be reinforced before the construction of the anchor wall. After various investigations and demonstrations, the construction party adopted the SMC and other thick cement-soil mixing wall process as the first process of the anchor-continuous continuous wall.

Jintai SC series hydraulic milling and mixing drilling rig combines the two-wheel milling groove forming process and the traditional deep cement soil mixing process. The product is equipped with a digital operating system and is highly integrated with the automatic slurry mixing background. The milling wheel attitude can be adjusted in real time through the console of the operation room , Control working parameters such as tunneling, lifting speed and grouting pressure to achieve information control of the construction process. After one month of construction verification, as a reinforcement measure for the ground groove wall foundation, SC55 is superior to the traditional SMW mixing pile process in terms of construction continuity, wall uniformity, and construction efficiency.

According to some data, it is the first time in the domestic bridge engineering to use the SMC construction method to reinforce the groove wall of the bridge's circular anchorage foundation. It can be predicted that this process will play a vital role in the reinforcement of the ground wall groove wall of the soft ground of the project and ensuring the quality of the ground wall groove.

Shanghai Jintai is the earliest domestic equipment manufacturer that has entered the field of pile foundation construction. It occupies a dominant domestic position in product technology innovation and new process equipment R & D and manufacturing. Both the construction efficiency and equipment stability indicators have reached international advanced levels. Editor / Zhao Jing

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~