- Forklift performance technology and application scenarios are constantly expanding the application boundary

This is just the beginning. The story is even better." At the 2022 World Manufacturing Conference, Ouyang Ming, academician of the Chinese Academy of Sciences, spoke highly of China's new energy vehicle industry - "to achieve an all-round take-off of quality and quantity, driving the automotive industry to change lanes and overtake."

In recent years, as industrial automation and intelligent manufacturing have become the mainstream trend, the development of logistics automation has become a general trend, and automated and intelligent handling tools, including unmanned forklifts, have also ushered in unprecedented development opportunities. Since 2022, affected by the special environment, enterprises have faced many difficulties such as low return rate and shortage of personnel. With the release of the latest census report in China, it is clear that it is facing the status quo of low fertility, the demographic dividend is facing the ebb tide, and the labor difficulty and labor shortage will be further intensified in the future development.

Various factors began to prompt enterprises to rapidly promote the pace of "machine replacement". From the perspective of market space, unmanned and intelligent forklifts are still in the growth period, and the overall market space is about 3 billion. In this new arena, there are many old companies transforming from traditional fuel vehicles, and even emerging mobile robot companies with a sensitive sense of smell.

Nobody breaks the game

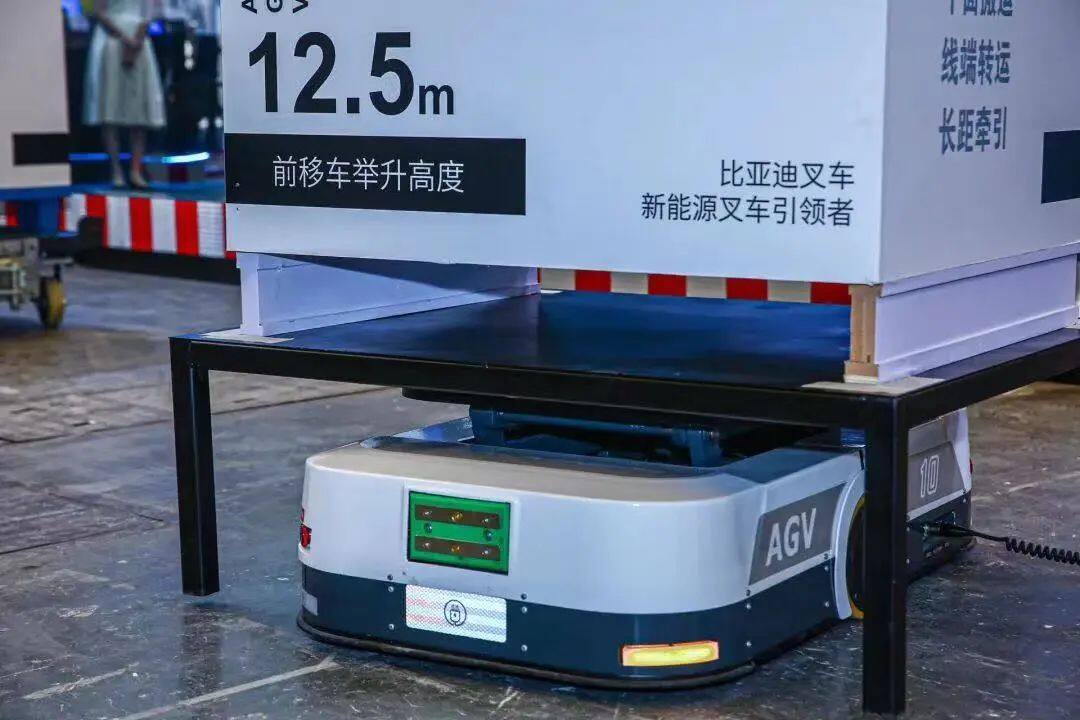

Compared with the large logistics of roads, railways and shipping, the intelligent logistics system of factories is mostly concentrated in the application scenarios of unmanned guided vehicles, that is, AGVs. Before 1992, it was extremely difficult to make a qualified AGV: there was no wireless communication technology, no suitable on-board computer, no algorithm and no database, and only through magnetic guidance could the specified path be reluctantly unmanned.

With the development of positioning technology, guidance technology and communication technology, especially the surge of computers, now when talking about AGV, there is almost no technical barrier, and it has become a question of how to use the technology well. BYD intelligent handling robot since its debut in Shanghai CeMAT ASIA in 2018, has formed a full-scene intelligent unmanned handling forklift network including forward, pallet, traction and other categories.

Autonomous navigation technology of industrial vehicles has always been the focus of the industry, the positioning accuracy of unmanned forklifts needs to reach the millimeter level, to reach this level, a large number of unmanned forklifts use a synchronous positioning composition of laser navigation, this technology is suitable for single control, in the multi-vehicle collaborative work scene is prone to interference. BYD forklifts can detect the application scene through liDAR, creating a map in real time to correct the location of the equipment. With ultrasound, ultra-long distance detection can also be achieved to ensure the operation of the non-contact safety design of the forklift during operation.

In the multi-vehicle collaborative work scenario, BYD forklift can use remote control driving technology to achieve a remote control to connect multiple vehicles, combined with advanced vehicle scheduling system, can monitor the operation of equipment in real time to better allocate resources and timely scheduling.

Intelligent upgrade

Although unmanned forklifts have entered a period of rapid development, intelligence seems to have become the "last kilometer" to persuade many enterprises to withdraw. In the unmanned field of BYD forklift has undoubtedly ushered in the peak, the next step is how to hold the peak, and find the intelligent landing point.

Taking BYDAR16P handling robot as an example, this forklift adopts industry-leading automation technology, which can provide professional intelligent logistics solutions, regardless of site and space restrictions; It can also reasonably plan paths, adjust tasks and flexibly avoid obstacles, in addition, the AR16P is also equipped with multiple safety protection, equipped with laser obstacle sensors, mechanical collision avoidance devices and sound and light alarms, safe operation is more guaranteed.

Not only that, in terms of cost control, BYD intelligent forklift trucks also have unparalleled advantages. Compared with traditional forklifts, BYD intelligent forklift can operate continuously for 24 hours, reducing the input of relevant personnel; Through the monitoring system BYD intelligent forklift can also realize the dispatch of multiple forklifts by one person, saving human resources.

At the 2023 CeMAT ASIA exhibition, which opened on October 24, BYD forklifts made a spectacular appearance with its handling robots, storage vehicles, counterweight forklifts and other series of products, once again demonstrating its strength in the intelligent and unmanned field. For the domestic unmanned forklift field with a penetration rate of less than 1%, the intelligent leapfrog upgrade of unmanned forklift enterprises to achieve lane overtaking in the world has become an obvious proposition.

There is an old Chinese saying: be modest and prudent in life and work, just like wheat, the lower the head, the fuller, the higher the head, the more empty the shell. But BYD forklifts seem to have entered the stage of anti-gravity development, and the head is raised high enough, but it is full enough. Now, a new round of sowing and growth is opened again, in the unmanned, intelligent forklift truck this field, the harvest of Chinese forklift enterprises will be what, no one knows. However, if the sower is BYD, this may be a drought and flood guaranteed things, as the beginning of the article, the story behind is more wonderful! Editor/Xu Shengpeng

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~