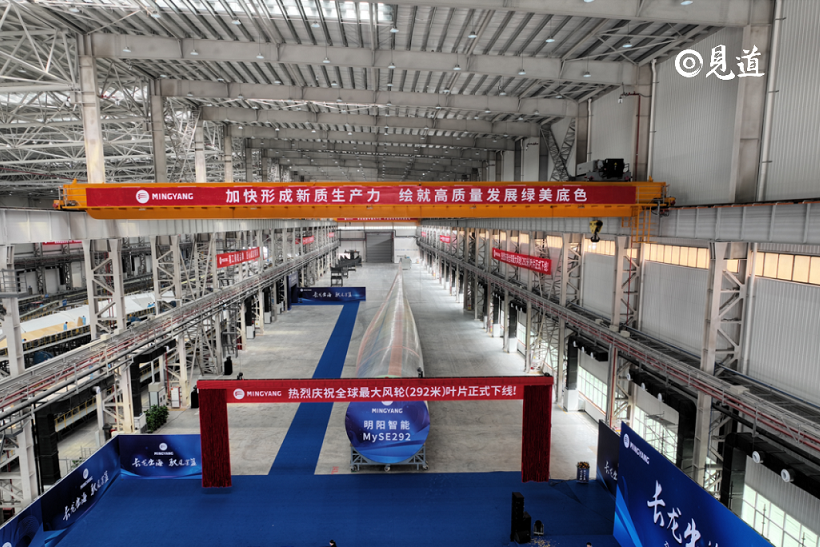

- The successful production of MySE292 offshore super large blades will strongly promote the development of the clean energy industry

On February 27, 2024, the MySE292 offshore super large blade independently developed by Mingyang was successfully taken offline at the Hainan Oriental Intelligent Manufacturing Base. This blade is suitable for a wide range of sea areas in Guangdong, Guangxi, Hainan, Zhejiang and other regions, and also lays a solid foundation for Mingyang to explore and layout the international market.

This wind turbine blade is 143 meters long and has a impeller diameter of 292 meters, making it the largest wind turbine blade in the world that has been offline.

The MySE292 offshore super large blade sweep area exceeds 66000 square meters, equivalent to the size of 9.4 standard football fields. The increase in blade length leads to a larger swept area of the wind turbine, capturing more wind energy. The blade will be installed on the MySE 18.X-20MW independently developed by Mingyang. The annual power generation of a single unit can reach 80 million kilowatt hours, which is equivalent to reducing carbon dioxide emissions by 66000 tons and approximately equivalent to the total annual electricity consumption of 96000 residents.

MySE292 offshore super large blades continue the typhoon resistance genes of Mingyang products and are suitable for super first-class offshore areas in Guangdong, Guangxi, Hainan, Zhejiang and other areas south of the Yangtze River. They can withstand super strong typhoons up to level 17.

In the design of this blade, Mingyang continues the high reliability requirements of wind turbine products, drawing on the wing design of aviation aircraft and adopting a wing family design. The overall streamlined design makes this blade have more excellent wind catching ability. In addition, the blade also adopts innovative aeroelastic cutting technology, which reduces the ultimate load of the blade while increasing its length and flexibility, making the maximum wind speed at the blade boundary close to 80m/s.

At the offline ceremony, Zhang Chuanwei, Secretary of the Party Committee and Chairman of Mingyang Group, stated, "Mingyang will fully leverage the world's leading equipment technology, application scenarios, and supply chain synergy advantages to achieve comprehensive production of the two major bases of Dongfang's main engines and blades globally, accelerate the construction of offshore wind power demonstration projects, promote the first large-scale ocean ranch project, and based on the world's first empirical project of" electric hydrogen ammonia alcohol "in deep sea, work together with global energy and chemical giants and top institutions to create the world's first million ton deep sea green electric hydrogen ammonia alcohol demonstration project, promote the construction of Hainan International Ocean Ship Green Refueling Center, drive the development of offshore wind power, marine energy, and electric hydrogen ammonia alcohol industry clusters, and build a new green economic system." Editor/Zhao E

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~