- The railway is the key for Chinese companies to enter the North African market

- The project can deeply participate in the country's economic transformation and accumulate experience for other African projects

Algeria has become a huge railway construction site. The country has pledged to extend the line to its southernmost tip, to Adrar and Tamanrasset, and to the borders with Mali and Niger.

Major mining routes are also being built, with trains bringing phosphate from Tebessa to the port of Annaba in the east and iron ore from Qara-Djebilet (Tindouf) to Béchar and Oran in the southwest.

The owner of all these projects, the National Railway Investment Research Agency (Agence nationale d'études de suivi des investissements ferroviaires, or Anesrif), shared scenes from the construction sites of two sections of the Tébessa and Gara Djebilet lines.

The methods used are impressive. This is the first time they are used in Algeria and they will allow all lines, despite their length, to be delivered on time.

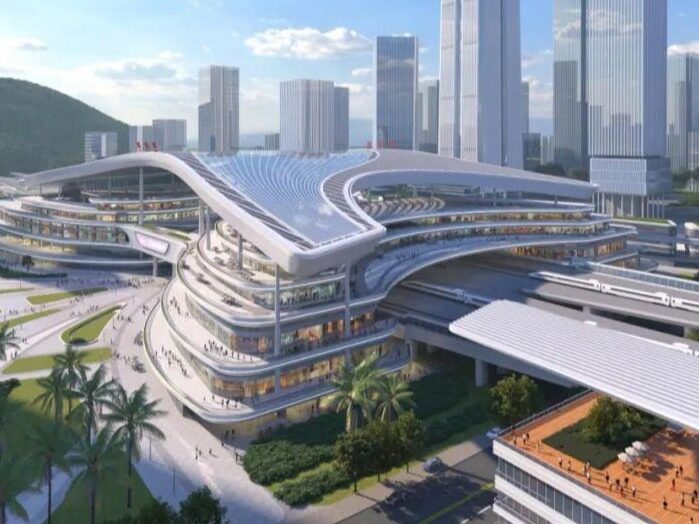

Algeria is implementing an impressive railway project

The Baikal-Tindouf line is 950 km long. Laying such a long track would take many years if "normal" methods were used, especially in a desert environment and under extreme climatic conditions.

But the China Railway Construction Corporation (CRCC), which is in charge of the project with its Algerian partners, brought in a huge machine: a "train" that lays down the sleepers and rails at the same time, then drives over them at once.

But how is this possible if the track has not yet been laid? The machine Anesrif showed was working on the 135km Tindouf-Gala-Djebilet section.

Algeria: When the Chinese laid 3 kilometers of railway every day in the desert

The sleepers used are adapted to the desert environment and the mining nature of the railway and are therefore able to withstand extreme weather conditions and enormous weight.

The 18-meter-long rails are assembled on site in a dedicated welding workshop to form a 500-meter-long line.

After the sleepers and rails are placed in the train, the train is precisely positioned at an extremely fast speed. The workers only need to fix the rails manually. The project manager revealed: "The completion rate using this method is 3 kilometers per day.

"More than 40 kilometers out of 135 kilometers have been laid. This is the first time such a machine has been used in a railway project in Algeria or Africa," he added.

Construction has already begun at the site and currently the reinforced concrete beams are being laid. The reinforced concrete beams are being manufactured in a workshop at the site.

Anes Rif shows a 5-kilometer-long earthwork project designed to bypass the town of Drian in Taf province. Innovative technologies are also used here due to the special nature of the area, which is prone to flooding. In the heart of the scorching Sahara Desert, an infrastructure miracle that shocked the world is taking place! Algeria has launched an epic railway project, and the steel dragon of China Railway Construction is advancing in the golden sea of sand at an astonishing "Chinese speed". This is not an ordinary railway, but a "golden channel" that rewrites the fate of North Africa - it connects mineral treasures worth hundreds of billions, connects the border trade of three countries, and carries the dream of taking off for the entire region!

Algeria's railway revolution is not only a leap forward in infrastructure, but also the key for Chinese companies to enter the North African market. Through the combination of "infrastructure + resources + digitalization" strategy, we can deeply participate in the country's economic transformation and accumulate experience for other African projects. (This article is from the official website of Seetao www.seetao.com. Reprinting without permission is prohibited. Otherwise, it will be investigated. Please indicate Seetao.com + original link for reprinting) Seetao.com Strategy Column Editor/Sun Fengjuan

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~