- A complete set of construction equipment system for mining tunnels, covering various core equipment

In recent years, the complete set of construction equipment system for mining tunnels has been widely applied in water conservancy engineering with its intelligent, efficient, and collaborative operation mode. It effectively solves the efficiency, safety, and quality problems in the construction of water conservancy engineering tunnels, promoting the transformation and upgrading of water conservancy engineering construction towards mechanization and intelligence.

To solve the problems of low manual operation efficiency and high safety risks in water conservancy tunnel construction, relevant companies have developed a complete set of tunnel construction equipment system covering core products such as cantilever tunneling machines, rock drilling trolleys, wet spraying trolleys, arch installation trolleys, anchor rod trolleys, etc., based on their experience in mining tunnel construction. Through efficient collaboration between equipment, the safety, efficiency, and quality of tunnel excavation support have been significantly improved, especially in complex geological conditions where advantages are evident.

Jumbo

To solve the problems of low efficiency, large number of personnel, and poor accuracy in traditional manual drilling, the new generation of intelligent three arm rock drilling rig can complete various operations such as tunnel drilling and blasting holes, anchor holes, etc., achieving mechanization in drilling, blasting, and support processes. In the Yangtze River Diversion Project, the DJ3E three arm rock drilling rig significantly reduces the number of construction personnel and also has intelligent functions such as automatic hole layout and one click rock drilling. The wear and tear of drilling tools is reduced by more than 30% compared to conventional equipment, greatly optimizing construction efficiency. The three arm rock drilling rig has achieved intelligent drilling in hard rock tunnels.

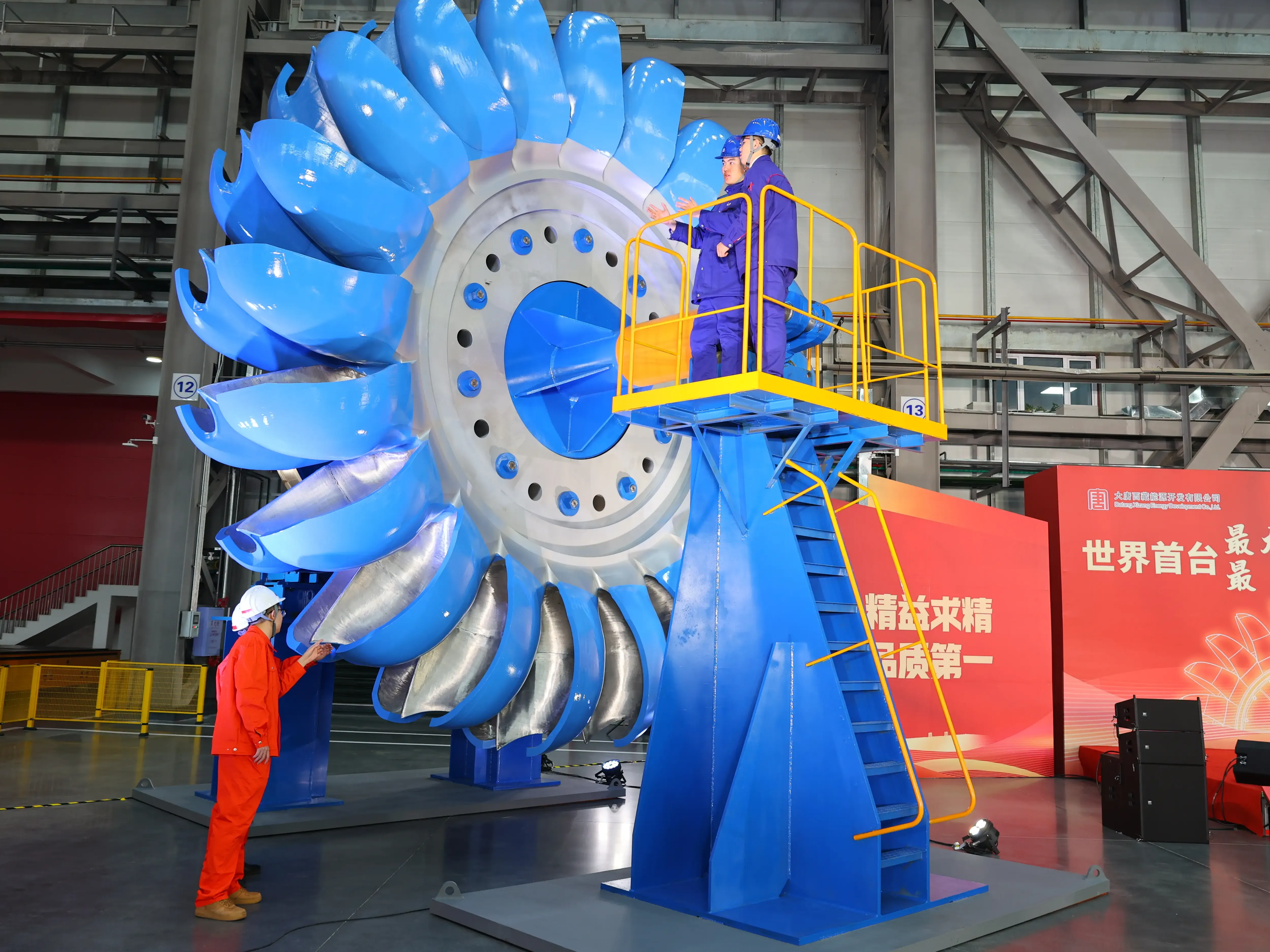

boom-type roadheader

For soft rock geology, cantilever tunneling machine is a key tool for continuous and low disturbance excavation. CTR series cantilever roadheader integrates cutting, traveling, shipping, and spray to eliminate dust. It has the characteristics of high mechanization, small damage to surrounding rock, good section shaping, and easy control of overbreak and underbreak. In the Inner Mongolia Yinchuo Jiliao project, the CTR323 cantilever tunneling machine was used to cope with the complex conditions of poor integrity and low stability of the 500m tunnel surrounding rock. With the advantages of low disturbance and continuous operation, it achieved safe and efficient construction, fully demonstrating its applicability in complex geological conditions.

Concrete wet spraying trolley

The HP series concrete wet spraying trolley is designed specifically for tunnel support. In the Miluo Pumped Storage Power Station project in Hunan, the HP3017B wet spraying trolley performed outstandingly, with a maximum spraying volume of 30m ³ per hour, which is 8 times that of traditional dry spraying machines. It effectively achieved a breakthrough in the efficiency of tunnel support and demonstrated significant advantages in tunnel support operations. After the wet spraying trolley completes the initial concrete spraying, the intelligent anchoring trolley immediately carries out anchor reinforcement, forming a mechanized closed loop of spraying and anchoring.

Intelligent anchor injection integrated trolley

The MT series intelligent anchoring and grouting integrated trolley integrates functions such as drilling, installation, and resin mixing. It only takes 4-5 minutes to construct a 4m low prestress expansion shell hollow grouting anchor rod, and 7-8 minutes to construct a resin hollow grouting anchor rod. Compared to traditional construction, its quality is more reliable, with a 60% increase in comprehensive efficiency, and it is suitable for a variety of anchor rod types, with high construction reliability and fast speed. It has been applied in projects such as Funing pumped storage and river diversion to supplement the Han River, demonstrating significant advantages.

Arch installation trolley

The GJ3G multi arch installation trolley is used for mechanized arch support operations and can support single arch, multiple arch, and prefabricated folding arch assembly. It can lift four arch frames at once and is suitable for various types of arch frames such as steel and grating. In the Yangtze River Diversion Project, this equipment can complete the assembly and positioning of four arches in 35 minutes, and complete the entire process of four arches (including measurement, marking, risk elimination, arch erection, mesh reinforcement welding, etc.) within 2 hours. The efficiency is improved by more than 30% compared to traditional manual arch erection, significantly enhancing the efficiency of arch support. (This article is from the official website www.seetao.com of Jian Dao. Reproduction without permission is prohibited, otherwise it will be prosecuted. Please indicate Jian Dao website+original link when reprinting.) Jian Dao website infrastructure engineering column editor/Wang Xia

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~