- In this CIIF, Agile Robots has launched new products and applications such as H10-W, TekkenD+VT10-G, Engine Assembly, etc

From September 23rd to 27th, 2025, Agile Robots will showcase multiple innovative products at the CIIF Shanghai National Convention and Exhibition Center, attracting many visitors to stop and experience and engage in in-depth exchanges!

We sincerely invite you to visit booth A226 in Hall 8.1H and explore intelligent robot solutions with us!

In this CIIF, Agile Robots has launched new products and applications such as H10-W, TekkenD+VT10-G, Engine Assembly, etc!

1、 General field

H10-W

H10-W is an intelligent robot designed for scientific research, education, business, and consumer fields. Its motion mechanism consists of a wheeled chassis, two 7-degree-of-freedom arms, and a linear lifting torso. It supports users to interact through voice commands (such as object retrieval and placement commands), and the robot executes target grasping, transportation, and placement tasks according to the user's voice commands.

Mobile FR3 Duo

The FR3 Duo dual arm robot integrates a mobile chassis and dual arms, achieving coordinated control between the chassis and the robotic arm, and maintaining precise positioning of the actuators during movement; The system has intelligent self optimization capabilities, which can autonomously improve execution efficiency, shorten task duration, and adapt to high difficulty tasks in dynamic environments such as warehousing, handling, and service robots as the number of task executions increases.

A highly flexible research grade mobile robot platform designed specifically for remote control, mobile operations, and intelligent research scenarios optimization. The system is natively compatible with FR3, supports plug and play integration, and can quickly deploy experimental environments, helping researchers focus on algorithm development and application innovation.

Agile Hand

Agile Hand is a high degree of freedom humanoid five finger dexterous hand that is close in size to a human hand, with excellent flexibility and can adapt to complex work scenarios, suitable for various grasping and assembly tasks.

It consists of five identical modular mechanical fingers, with carefully designed joints, dimensions, shapes, and degrees of freedom. In addition, it can be upgraded and equipped with an opposing thumb actuator, with a total degree of freedom of 16. This design further enhances flexibility and simulation accuracy.

Diana/Thor series

Diana3/Diana7 G2

The Diana series is a high-precision intelligent force control robotic arm developed by Agile Robots. The joint is equipped with high-precision torque sensors, which have high sensitivity for force control and collision detection. The relative accuracy of force control can reach up to 0.5N, and the repeatability accuracy is 0.05mm. The use of a seven degree of freedom redundant design improves the robot's motion flexibility, and zero space control technology enables the robot to flexibly avoid obstacles in a limited workspace, making it easy to adapt to more complex application scenarios.

Thor3/Thor7

The Thor series is a 6-degree-of-freedom intelligent robotic arm developed by Agile Robots, which covers performance requirements for loads of 3kg~20kg and working radii of 600mm~1700mm.

The maximum repeat positioning accuracy can reach 0.03mm, supporting collision detection and graphical programming, easy to operate, and can be easily deployed quickly. Suitable for various application scenarios such as assembly, loading and unloading.

TekkenD + VT10-G

Tekken D

Tekken D is an electric two finger gripper designed for intelligent applications, which integrates force feedback on the basis of traditional grasping functions and supports both position control and force control modes. Its fingertips can be optionally equipped with a visual tactile sensor VT10-G, which combines tactile data to perform more flexible and precise grasping operations.

VT10-G is a universal visual tactile sensor that can be flexibly adapted to various two finger grippers, including a processing box and two sensor modules.

The processing box has real-time data processing capabilities and can synchronously output high-precision raw RGB images, dynamic force field distribution maps, depth images, and 3D point clouds and other multimodal information, providing precise tactile perception support for robot grasping operations.

2、 Health and physical therapy industry

X-SPA

During the implementation period, a large number of professionals from both inside and outside the industry came to experience and visit, and this innovative experience combining traditional Chinese medicine therapy and robotics technology had a great effect!

The X-SPA intelligent rehabilitation therapy robot is an innovative therapy product that integrates moxibustion, dot matrix waves, and endogenous heat functions. It can be flexibly applied to various scenarios such as homes and rehabilitation institutions, meeting the needs of different user groups to improve physical function and maintain health.

The robot is equipped with a quick change three in one function terminal, and a single device can achieve three types of therapy functions; Equipped with Pad operating terminal and cloud service platform, the operation is convenient and efficient; Adopting intelligent visual technology, it can easily adapt to users of different body types; At the same time, professional physical therapy courses and high-precision force control systems are implanted to provide users with a professional and comfortable physical therapy experience.

3、 Automotive industry

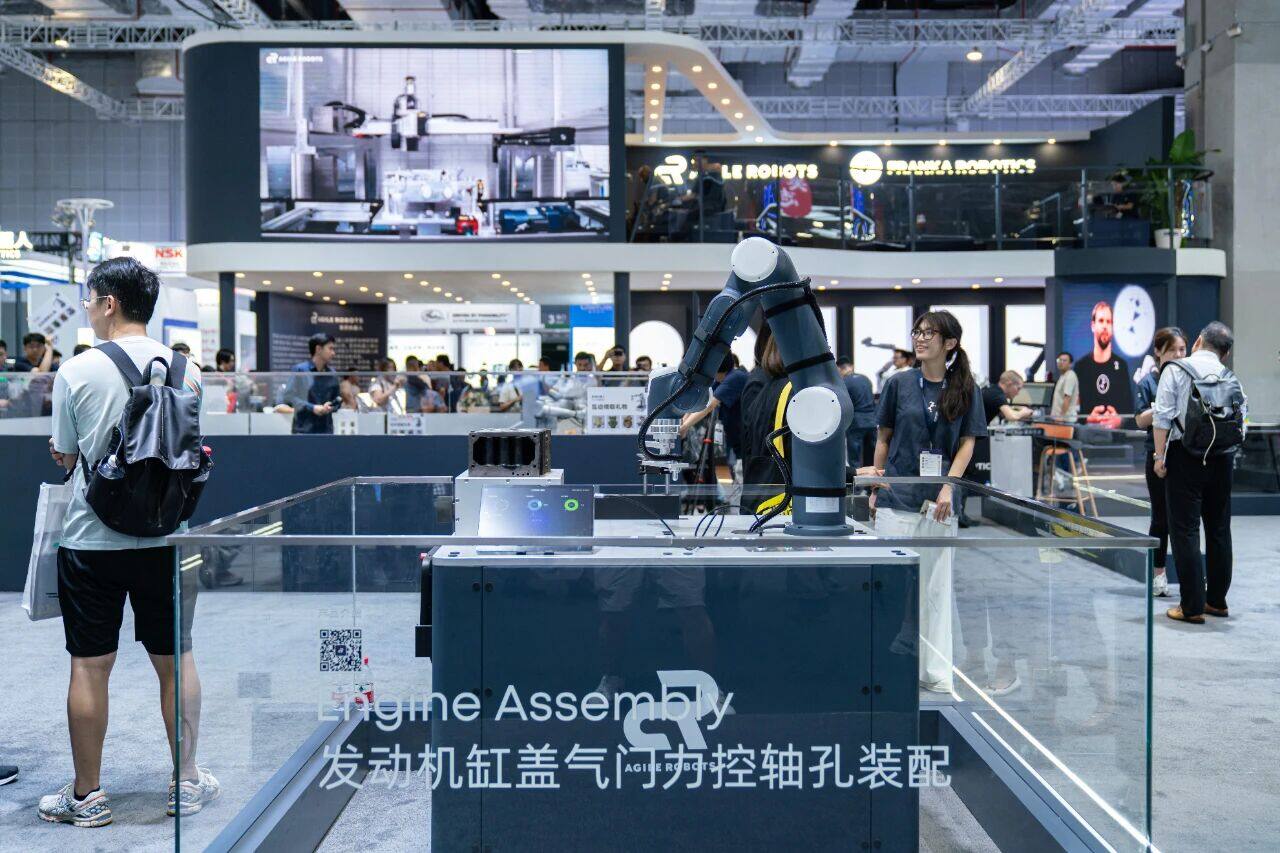

Engine Assembly

Agile Robots has developed automation for the engine cylinder head valve drilling process in the automotive industry, simulating the actual production assembly process of engine cylinder head valves.

This solution uses Agile Robots' self-developed Thor7Pro collaborative robot to perform assembly operations, and uses force control function to monitor the real-time force during the process of inserting parts into the valve hole, accurately determining whether the valve is inserted into the valve hole.

This solution can effectively solve the problems of jamming and component damage caused by positional deviation in traditional shaft hole assembly, and has significant advantages in precision component assembly scenarios such as engine cylinder heads and valves, helping the automotive industry improve production efficiency and ensure product safety and quality.

4、 Education and research industry

FR3 Duo/FR3

Force-Sensitive Teleoperation

The FR3 Duo dual arm system, paired with the independently developed Joystick handle, can demonstrate high-precision "master-slave" dual arm remote operation. Among them, one FR3 Duo is paired with a joystick as the "master end", while the other mirrors its actions as the "slave end" and synchronously collects operational data; The operator can perceive the interaction process in real-time through force feedback, achieving precise control of the "slave" robot. Meanwhile, the motion and visual data recorded by the system can be used to support imitation learning and intelligent training.

Gr00t N1.5

The system integrates two FR3s on the same base, forming a dual arm architecture. With the help of onboard Gr00t N1.5 (Universal Robot Basic Model, Generalist Robot Foundation Model), Robots can parse the visual and data collected by sensors, understand environmental contextual information, and autonomously complete tasks without the need for scripts.

This solution not only accelerates the deployment of scientific research projects and reduces integration costs, but also promotes the leap in the intelligence level of general-purpose robots, providing strong support for the research of robot generalization.

Franka SpaceMouse Teleoperation

Through 3Dconnexion's SpaceUse, remote control of the FR3 robotic arm can be achieved, supporting real-time Cartesian velocity control. This solution is ready to use out of the box and integrates the ROS 2 framework, providing a smooth and efficient remote operation experience for scientific research and development work.

FR3 Duo Artistic Fan Painting

When using the FR3 dual robotic arm to hold a pen and draw patterns, the pen tip pressure is adjusted in real-time through force control technology to ensure even and smooth writing lines; At the same time, combining machine vision assistance to locate writing points and accurately control the drawing trajectory.

This application fully demonstrates the technological advantages of Agile Robots in high-precision control, agile operation, and force perception, providing a new path for the automation inheritance of fine cultural handicrafts.

Agile Robots can provide seamless collaborative solutions covering the entire automation industry chain, building trust and stimulating creativity through on-site interaction, and assisting in the development of innovative technologies that meet practical needs through face-to-face communication!

Action is better than excitement! The secret to real scene interactive experience and upgrading production line, come and ask!

Our engineers and team have prepared the answers for booth A226 in Hall 8.1H. We are now starting our technical speed chat and solution docking!

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~