- This will provide key component support for scenarios such as the 800V high-voltage platform for new energy vehicles

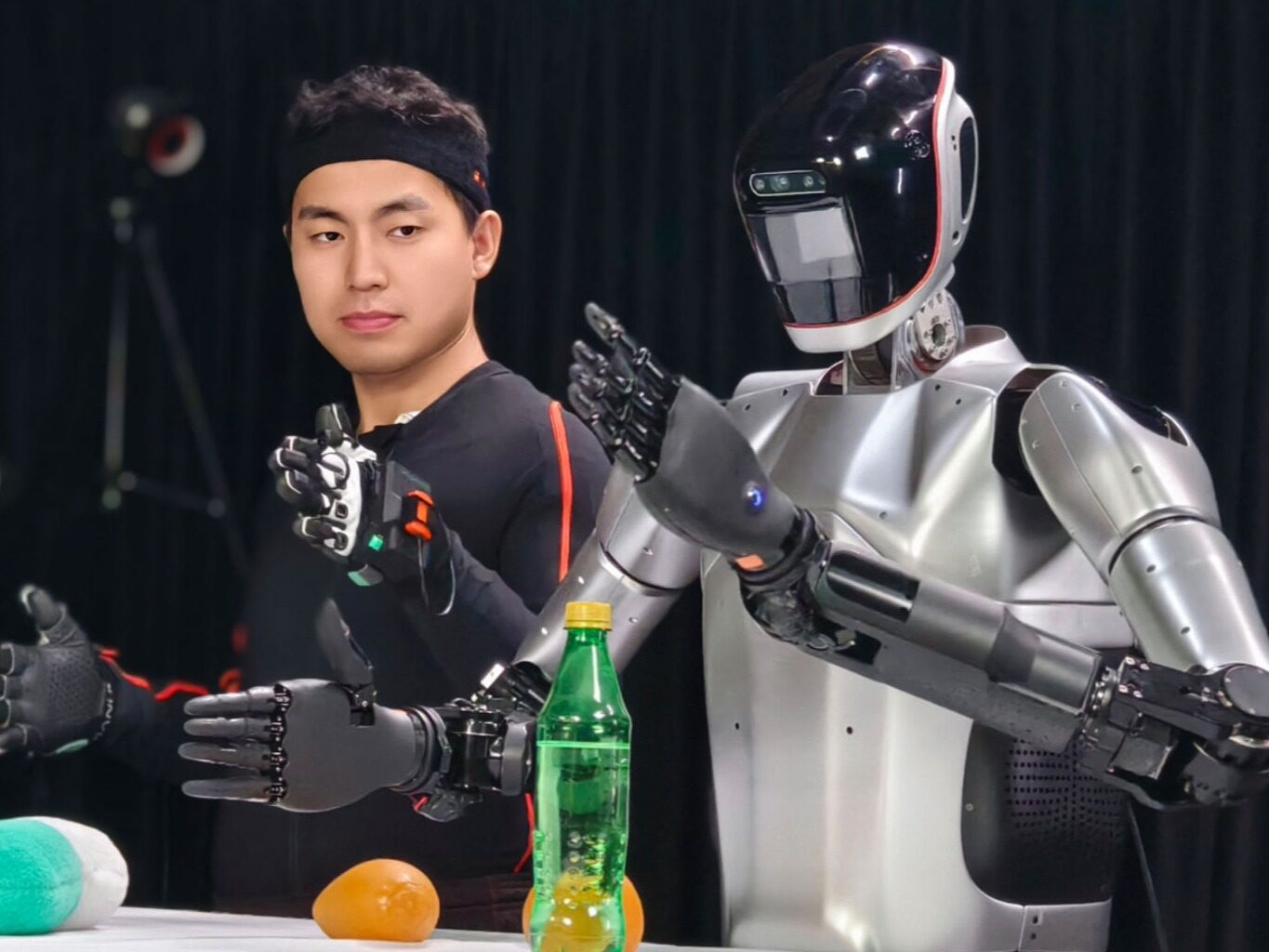

- The project will achieve a deep integration of advanced European technology and Chinese manufacturing capabilities

At the end of 2025, China's compound semiconductor industry will reach a key milestone - AnYi Semiconductor (Chongqing) Co., Ltd., a joint venture between Sanan Optoelectronics and STMicroelectronics, officially announced that multiple 8-inch automotive grade SiC power devices have completed verification and entered the risk mass production stage, marking the countdown to the large-scale implementation of this semiconductor benchmark project with a total investment of 23 billion yuan.

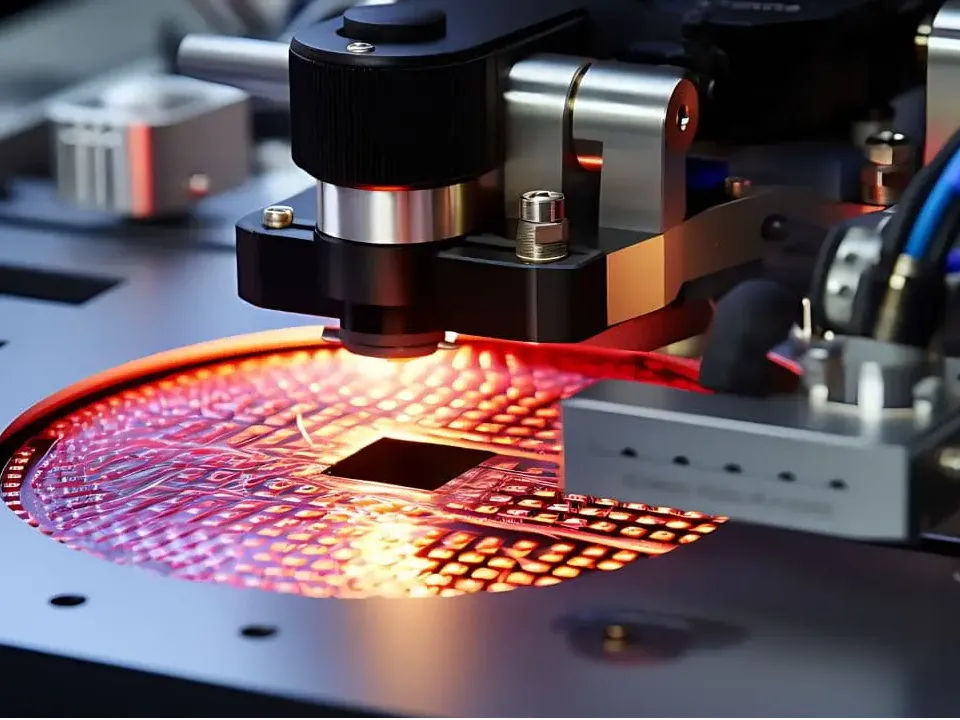

As an industry benchmark jointly created by Chinese and European semiconductor giants, AnYifa is owned by Sanan Optoelectronics with 51% and STMicroelectronics with 49%. Its core focus is on the epitaxial and chip manufacturing of 8-inch SiC power devices, and its products will be exclusively supplied to STMicroelectronics, widely applicable to high-end scenarios such as new energy vehicle main drive inverters, industrial power supplies, and energy storage systems. Compared to traditional 6-inch wafers, 8-inch SiC chips can increase the number of single chip cores by 78%, significantly reducing unit manufacturing costs and laying the foundation for the large-scale popularization of SiC devices.

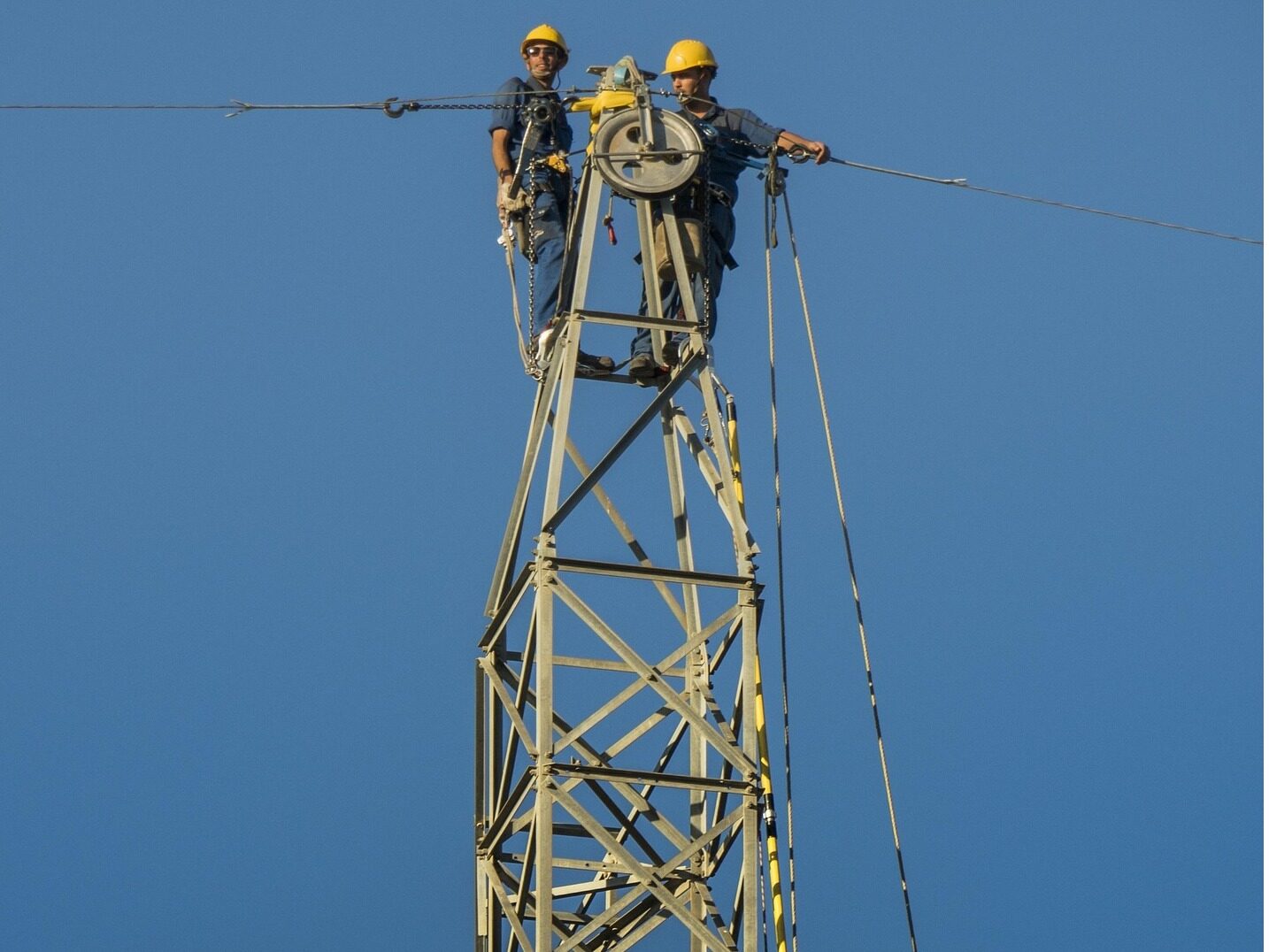

Since its establishment in August 2023, the project has maintained an efficient pace of progress: construction began in September 2023, the "lighting up" conditions were achieved in November 2024, the line was officially put into operation in February 2025, product reliability verification was launched in September, and now it has smoothly entered the risk mass production stage, fully meeting the expectations of the previous plan. According to the plan, the annual production capacity of the project after full production will reach 480000 pieces (approximately 10000 pieces per week), and it is expected to achieve full production by 2028. At that time, it will become an important global automotive grade SiC device manufacturing base.

Industry insiders point out that risk mass production is a key link connecting small batch verification and large-scale production. The core goal is to expose and solve core issues such as process stability, product yield, and long-term reliability through trial production, laying a solid quality and cost foundation for subsequent large-scale production. At this stage, the products will mainly focus on verification and small-scale supply, and will provide key component support for scenarios such as the 800V high-voltage platform of new energy vehicles.

It is worth noting that this cooperation has established a complete localized supply chain from SiC substrates, epitaxy, chips to packaging and testing: Sanan Optoelectronics exclusively supplies 8-inch SiC substrates to the joint venture factory, while STMicroelectronics relies on its automotive grade technology accumulation to ensure product quality. The final product will undergo packaging and testing at the Shenzhen backend factory. This collaborative model not only strengthens the autonomy and resilience of China's SiC supply chain, but also achieves deep integration of advanced European technology and Chinese manufacturing capabilities, providing a new paradigm for global semiconductor industry cooperation.

Against the backdrop of the continuous increase in the penetration rate of new energy vehicles and the accelerated popularization of 800V high-voltage platforms, the smooth progress of the Anyifa project is timely. Data shows that the market size of China's automotive grade SiC power devices is expected to exceed 10 billion yuan by 2025, and an industry scale of over 50 billion yuan will be formed by 2030. The mass production and implementation of this project will effectively alleviate the supply gap of high-end SiC devices in China, provide core support for the improvement of new energy vehicle range and industrial energy efficiency optimization, and promote China's semiconductor industry to occupy a favorable position in the global third-generation semiconductor competition pattern.Editor/Bian Wenjun

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~