- China Railway Construction won the National Quality Engineering Award, China Railway Construction was recognized

On December 1st, the list of the first batch of national quality engineering awards for 2020-2021 was officially announced. The Longchuan-Huaiji Highway (Longchuan-Lianping Section) project of Guangdong Province, which was built by China Railway 23rd Bureau Group Co., Ltd. The Rock (Slate) Tunnel Project won the "National Quality Engineering Award"

Longchuan-Huaiji Highway (Longchuan-Lianping Section) Project

The Longhuai Expressway has a total length of 364.82 kilometers and crosses 4 cities and 8 counties. It is an important section of the Shantou-Kunming Expressway in the national expressway network. It is the project with the longest mileage and largest investment in the history of expressway construction in Guangdong Province. The total investment of the project 40.217 billion yuan. Longhuai Expressway passes through the mountainous area of northern Guangdong with complex geological environment. It is a typical alpine landform, and its engineering construction difficulty is also the most difficult in the history of highway construction in Guangdong Province.

The TJ5 section (K29+550~K39+300) undertaken by the three companies has a total length of 9.75 highways and a total contract cost of about 360 million yuan. The starting point is located on the south side of Litian Village, Shangguan Town, Dongyuan County, and the Litian tunnel is set to the west to Xu Village. After crossing the township road 271 on the south side of Wanyao Reservoir twice, the Chuantang service area is set up, and the route crosses the Longjiang River to the west. , Proceed along the dividing line between Chuantang Town and Zhangxi She Nationality Township, and the end point is at Longjiang Village, Chuantang Town.

Litian tunnel under construction

Objective factors such as complex geological structure, backward traffic, blocked communications, and "microclimate" in mountainous areas all year round in the project bid section have brought great challenges to the construction. Since entering the site in May 2015, the project department has successively overcome difficulties such as steep terrain and complex geology, completed the construction of the main line construction access road, and solved the problem of difficulty in entering the site. At the same time, it actively responded to the standardized construction requirements of the Guangdong Provincial Department of Communications and the owner's unit, and always focused on standardized and refined construction. In the early stage of construction, the project department organized technical, management, and construction team personnel to conduct construction specification meetings to fully clarify the construction standardization process and details, and organize relevant personnel to conduct assessments to clarify standardization concepts and requirements and details. Faced with many pressures such as tight construction schedules, heavy tasks, and difficulties in demolition, all the construction personnel carried forward the spirit of "the railways have no dangers and obstacles in front of them". They united and cooperated to overcome difficulties and successfully achieved each key node goal. In the process of project construction, we have continuously strengthened quality awareness and process control, ensured the continuous improvement of project management and quality performance capabilities, strengthened the talent management mechanism, cultivated a group of high-quality talent teams, and laid a solid foundation for the enterprise to create excellence.

During the construction process, the project always adheres to the corporate value concept of "integrity, innovation, eternal, high-quality character", constantly sums up valuable experience in construction management, encourages all employees to participate, competes for the best, emphasizes and strengthens quality awareness, and always keeps in mind the "attitude decision Quality, craftsmanship guide quality, measures to ensure quality, details to improve quality". Strictly pay attention to construction details, regularly carry out internal project summary, penalize the inferior and reward the superior. Establish benchmarking teams and benchmarking projects within the tender section to ensure that the overall quality of the project is always within a controllable range. Adhere to the "quality project" as the goal and establish a good corporate image.

In order to achieve the goal of opening the Longhuai Expressway to traffic at the end of 2018, the project department carried out various construction and production organizations around important control engineering nodes. Through inverting construction schedules, scientifically and rationally supplementing resources, implementing the project leadership guarantee system, and consolidating technical solutions, strict quality and safety; implementation of parallel operations and flow operations are coordinated with each other, dynamic management, flexible grouping, and flexible organization have ensured High-quality, safe and efficient engineering construction. In accordance with the overall schedule and arrangements, various measures were actively implemented. In the three labor competitions organized by the owner, the project department stood out among the 16 bidding sections across the board and won the second prize twice in a row, and won the owner’s supervisor and brother bid Affirmation of the paragraph. It has laid a solid foundation for smoothly passing the handover acceptance and opening the whole line to traffic on schedule.

After the Longhuai Expressway is completed and opened to traffic, it will become the first east-west expressway in northern Guangdong, and the history of no direct expressway has ended in the four counties and 13 towns along the route. The east-west horizontal traffic in Guangdong Province will be faster and smoother, which will greatly promote the improvement of the national highway network, promote the revitalization and development of the eastern and western regions of Guangdong, and lead the social progress of the Heyuan mountainous area.

Huayan (Stone) Tunnel Project

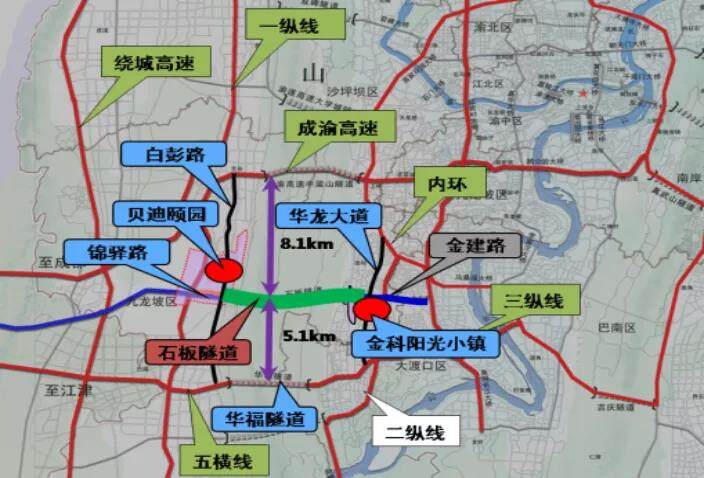

The Huayan Tunnel Project is one of the key municipal engineering projects in Chongqing. It is located in Huayan Town, Jiulongpo District. The tunnel is 8.1 kilometers away from the Zhongliangshan Tunnel of the Chengyu Expressway and 5.1 kilometers away from the Huafu Tunnel. It connects the east and west sides of Zhongliang Mountain. An important passageway. It is also an important control project to ease the traffic in the western part of Chongqing. The construction is difficult, the risk is high, the construction period is tight, and the standards are high. The Huayan Tunnel starts at the intersection of Baipeng Road and Jinyi Road, crosses Muchanggou, passes through Zhongliang Mountain, passes through Zhongliangshan Branch Railway, to Chongqing West Bulb Line, Jumping Link Line, and Chongqing West Railway Marshalling Station. After passing the Chongqing Fudao Steel Market, it is connected to the existing Jinjian Road in Jinke Sunshine Town. The total length of the left and right holes of the Huayan Tunnel are 4,962 meters and 4,974 meters, respectively. The tunnel is an extra-long tunnel. The start and end pile numbers of the left and right tunnels of the third contract section undertaken by the four companies are Z(Y)K3+500—Z(Y)K5+815, with a single tunnel length of 2315 meters and a double tunnel length of 4630 meters. The contract duration of the project is 987 days, and the total contract investment is about 470 million yuan. The project started in March 2014, completed in August 2017, and opened to traffic in November 2017.

The construction environment of the Huayan Tunnel Three-Bid Project is complicated and coordination is difficult. The project is located at the junction of urban and rural areas. The tunnel exit opening is adjacent to the Chongqing West Railway Freight Station line. The terrain is complex, the site is small, and the layout of temporary facilities is difficult; and the surrounding residential buildings are densely populated, making demolition difficult. As a result, the existing slag transportation roads are narrow, frequent traffic, and many bends. Both sides of the road are houses, which cannot be widened, and transportation coordination is difficult. The buried depth of the open tunnel is 20 meters. The open tunnel of the tunnel is adjacent to the existing line and residential buildings. There are many unpredictable factors in tunnel construction. Blasting vibration and flying rocks will affect the safety of the existing line and residential buildings. The project department is taking effective protective measures while taking effective protective measures. Conduct controlled blasting, monitor the blasting vibration speed, and monitor the deformation of neighboring existing buildings. In response to the difficulty of pumping and drainage, emergency plans and measures for strong drainage of sudden water inrush accidents in tunnels and strong rainstorm surface water flowing into the open tunnel entrance were formulated.

The Huayan Tunnel is the longest tunnel among the several tunnels passing through Zhongliang Mountain in Chongqing. It has a complex geological structure and high safety risks. The normal excavation section of the tunnel is 144.6 square meters, and the widened section is 188.74 square meters. The excavation section is easy to collapse. During the construction, the excavation method needs to be adjusted continuously according to the level of the surrounding rock to ensure the safety of the excavation construction. During the construction of the tunnel, it passed through the water inrush section of ZK3+950-ZK3+980 section, YK4+150-YK4+180 section fault mud outburst section, ZK5+038-ZK5+078 coal seam section and YK5+060-YK5+ 080 Goaf and other construction high-risk bad geology. Special plans and emergency plans have been formulated for the mud and water inrush, coal seam gas and harmful gas in the tunnel's poor geology, and adopted TSP advanced geological forecast, geological radar, fully automatic tunnel section instrument, infrared water detection, horizontal drilling and other monitoring Effective measures such as measuring instruments, equipment and comprehensive monitoring technology have solved the construction problems such as grouting and water blocking in the rich water section, water gushing from cavities and fault silt. In order to ensure the safety of construction, strictly control the cycle footage, implement the support system in time, strengthen the monitoring and measurement of the surrounding rock, pay attention to the deformation of the surrounding rock, and keep all unsafe factors under control. Minimize the high construction risks of the tunnel with poor geological sections, ensure the safety of construction, and realize the smooth completion of the entire tunnel as scheduled.

During the excavation of the Huayan Tunnel, the construction was carefully organized, the construction quality was strictly controlled, and advanced construction techniques and the "four new" technologies were widely promoted. All concealed projects entered the next process after passing the self-inspection and supervision inspection. After the overall construction of the tunnel is completed, the construction plan and construction technology fully meet the requirements of the specification, the internal quality of the project meets the qualified standard, the appearance quality is good, the partial acceptance, and the unit project acceptance are all passed at one time. The Chongqing Quality Supervision Station, Chongqing Urban Construction and Development Co., Ltd., China Coal Science and Industry Group Chongqing Design and Research Institute Co., Ltd., third-party inspection and other related units have performed ordinary inspections and non-destructive testing methods on the steel arch and invert of the tunnel. , The second lining is tested, and all meet the design and specification requirements, and the tunnel penetration error is small, and the penetration surface has achieved the effect of smooth blasting. There were no safety accidents during the construction of the project, and it was well received by the owners and supervisors.

After the unremitting efforts of all the staff of Huayan Project Department, the construction task was successfully completed. The Huayan Tunnel will play an important role in the economy of the Jiulongpo district of Chongqing. Up to now, the four companies have won 4 national quality engineering awards.Editor/Xing Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~