- It provides a guarantee for safe construction and shows the excellent strength of China's high-end equipment manufacturing technology

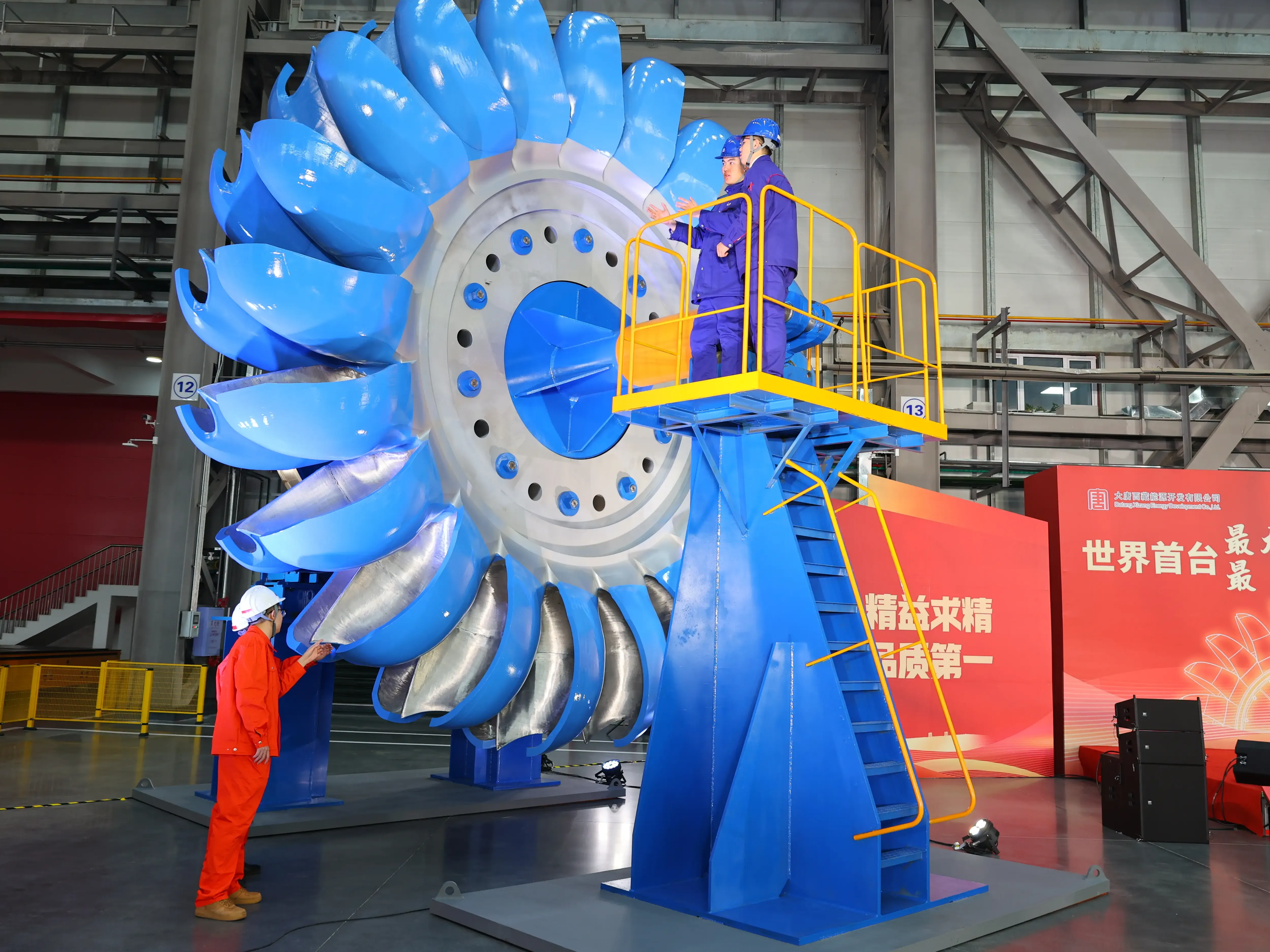

Following the successful completion of the first section of the Thai natural gas pipeline laying project on February 7, the project announced another success on March 28, 2024. The domestic minimum diameter (φ0.914 meters) rapid paving machine independently developed by Railway Construction Heavy Industry completed a remarkable 840 meters of excavation construction in just 15 days, during which more successfully passed through a number of wire tower piles, accurately helping the second section of the tunnel through. This feat not only refreshed the world record of the same level of pipe diameter pipe excavation construction, but also marked that the domestic rapid paving technology has been among the world's advanced ranks, highlighting China's strong strength in the field of high-end equipment manufacturing.

It is reported that the first phase of the Thai natural gas pipeline project is located in the south of Bangkok, with a diameter of 0.914 meters. The length of the construction section is 840 meters, divided into 11 sections, each section is about 78 meters, and the whole line must pass through the middle of the pile foundation of the high-voltage wire tower, and the cumulative need to pass through 5 pylons, and the distance between the pile foundation of the wire tower is only 3 meters, which is extremely difficult to construction.

Since its inception on March 13, the excavation speed has been stable at 0.6 meters per minute, which means that the construction of a single pipe (78 meters) can be completed in less than 3 hours, and the rest of the time is used for pipeline connection operations, and the top of 840 meters of pipe can be completed in only 15 days.

For extreme working conditions such as ultra-small diameter, ultra-long distance and curve tunneling, the new guidance system developed by China Railway Construction Heavy Industry is comparable to the "wisdom eye" of underground engineering, making the equipment successfully traverse accurately between the five electric tower piles along the way, and the overall horizontal construction accuracy is controlled within 10 cm, and the precision control has reached the world's leading level. Fully verified the stability, efficiency and advanced nature of the equipment, further consolidated the authority of the Railway Construction Heavy Industry in the field of international tunnel equipment, and provided strong support for the extremely complex working conditions of pipeline construction and global equipment intelligent technology. Editor/Wang Tian

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~