- This project builds an innovative model for the coupled development of new energy materials and traditional chemical industry

On April 27, the site leveling project of the "Phosphorus, Sulfur, Titanium, Copper, Iron, Lithium and Fluorine" coupled cycle integration project in Kaiyang, Guizhou Province started, and the pile foundation construction of the main factory building was carried out simultaneously. It is planned to complete the construction of the first phase of the 600,000-ton lithium iron phosphate production line by the end of 2025.

It is understood that the "Phosphorus, Sulfur, Titanium, Copper, Iron, Lithium and Fluorine" coupled cycle integrated project is the first 10 billion-level project in Guiyang in 2025. It is a full-resource circular coupling industry demonstration project dominated by phosphorus.

The total investment of the project is 33.1 billion yuan. It is jointly created by the Guiyang Municipal Government and Guizhou Phosphorus (Group) Co., Ltd., China National Nuclear Huayuan Titanium Dioxide, China Mining Resources Group and other companies. It aims to build an innovative model of coupled development of new energy materials and traditional chemical industry through the integration of resources across the entire industrial chain.

The project construction content includes 1.4 million tons of ferrous sulfate heptahydrate, co-producing 400,000 tons of titanium dioxide, 600,000 tons of iron phosphate, 600,000 tons of lithium iron phosphate, 150,000 tons of lithium carbonate, 10,000 tons of lithium fluoride, 20,000 tons of lithium hexafluorophosphate, 100,000 tons of copper smelting, phosphogypsum decomposition to produce sulfuric acid, cogeneration project, and public utility project.

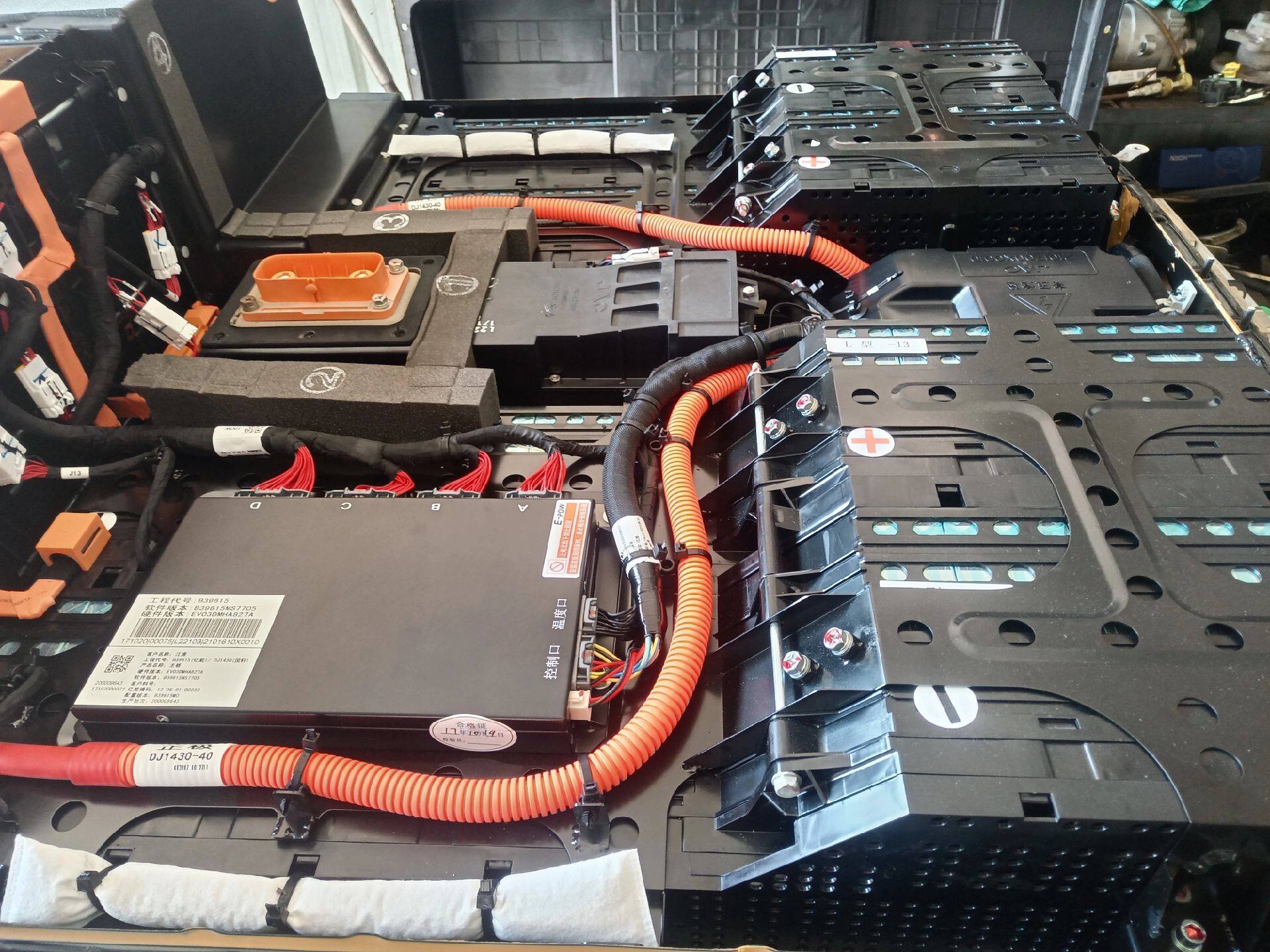

The project can form a complete chain of "resource mining - deep processing - terminal products". Phosphate ore is processed to produce iron phosphate, which is then combined with ferrous sulfate, a byproduct of titanium dioxide, to produce lithium iron phosphate, which is ultimately used in new energy vehicle batteries.

The project plans to complete the construction of the first phase of 600,000-ton lithium iron phosphate production line by the end of 2025. It will adopt a "build and put into production at the same time" model. It is expected that the first batch of production lines will be put into production in 2026 and the entire industry chain will reach full production in 2028.

The project directly targets the shortcomings of Guizhou's new energy industry, focusing on breaking through the supply bottlenecks of key resources such as lithium, iron, and copper. For example, the 600,000 tons of lithium iron phosphate production capacity can meet 15% of the country's demand for lithium battery positive electrode materials, while 10,000 tons of lithium fluoride and 20,000 tons of lithium hexafluorophosphate will improve the electrolyte industry chain. At the same time, the entry of leading titanium dioxide companies has filled the gap in Guizhou in this field.

After the completion of the above projects, Guizhou will become the world's largest production base of phosphorus-based positive electrode materials, accounting for more than 30% of the national market share.

"After the implementation of this project, the new energy industry of Guizhou Phosphorus Chemical Group will achieve self-sufficiency in lithium, iron and titanium resources, and the surplus lithium carbonate and ferrous sulfate heptahydrate can be supplied to other new energy companies in the province." said He Guangliang, Party Secretary and Chairman of Guizhou Phosphorus Chemical (Group) Co., Ltd.

It is reported that one out of every three phosphorus-based battery new energy vehicles in China is equipped with "Guizhou Phosphorus".

Guizhou Phosphorus Chemical Group believes that the current new energy industry is no longer a hot spot for everyone, but relying on the cost-reduction and efficiency-enhancing effects of the group's industrial synergy, the company's entry into the new energy battery positive electrode material industry track such as iron phosphate, lithium iron phosphate, and lithium hexafluorophosphate will form a competitive advantage of "leaning on a big tree to enjoy the shade."

At present, Guizhou Phosphate Group leads the country in phosphate fertilizer production capacity, with an annual production capacity of 2 million tons of wet-process purified phosphoric acid and a domestic market share of 64%, of which 54% is in the new energy sector.

At present, ferrous sulfate heptahydrate, a byproduct of titanium dioxide production, has become the main iron source for lithium iron phosphate production due to its low cost and stable supply. This is an important reason for introducing CNNC Titanium Dioxide into the project cooperation.

CNNC Titanium Dioxide is one of the leading companies in the rutile titanium dioxide industry, with an annual production capacity of 550,000 tons, ranking second in China. In recent years, with the gradual release of new production capacity and the impact of weak demand in some downstream industries, the price of titanium dioxide has fluctuated greatly, which in turn affected the profitability of listed companies.

Therefore, CNNC Titanium Dioxide is also striving to become stronger "outward". In 2023, when the price of titanium dioxide was at its lowest, it went to Guizhou to acquire phosphate assets, and added production and sales of major products such as phosphate rock and yellow phosphorus, creating a second growth curve for the company's performance.

In addition, the other partner, China Minmetals Resources, mainly engages in several business segments, including the development and utilization of lithium battery new energy raw materials, the development and utilization of rare light metal (cesium, rubidium) resources, and the solid mineral exploration and mining rights development business.

In 2024, China Mining Resources' lithium battery new energy raw material development and utilization business revenue was 3.129 billion yuan, accounting for 58.34% of total revenue, a year-on-year decrease of 26.25%. Lithium salt sales were 42,600 tons, a year-on-year increase of 145.01%. In Q1 2025, the company achieved lithium salt product sales of 8,964.43 tons, a year-on-year increase of 13%.

According to statistics, Guizhou Province's power battery production capacity has reached 37GWh, lithium iron phosphate cathode material capacity is 450,000 tons, ternary cathode material capacity is 108,000 tons, and anode material capacity is 374,000 tons, which has doubled compared to 2020. Among them, companies with lithium iron phosphate production capacity include CATL, BYD, Hunan Yuneng, Shenzhen Shengtun, Zhongwei New Materials, Zhenhua New Materials, and Anda Technology.(This article is from the official website of Jiandao www.seetao.com it may not be reproduced without permission, otherwise it must be investigated, please indicate Jiandao.com + original link) Jiandao.com strategic column editor / Sun Fengjuan

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~