- This marks the first time that China's self-developed G115 steel has been applied in engineering

At the construction site of the 630°C National Electric Power Demonstration Project in Yuncheng, Datang Shandong, with the commander's order, the 14-ton "secondary high-temperature reheater header" was slowly lifted and placed in place smoothly under precise control. As a key pressure component of the boiler system of the power plant, the equipment undertakes the important task of collecting and transporting high-temperature steam, and the internal steam temperature can reach 633°C during operation, creating a new record for the application of high-temperature resistant materials for thermal power equipment.

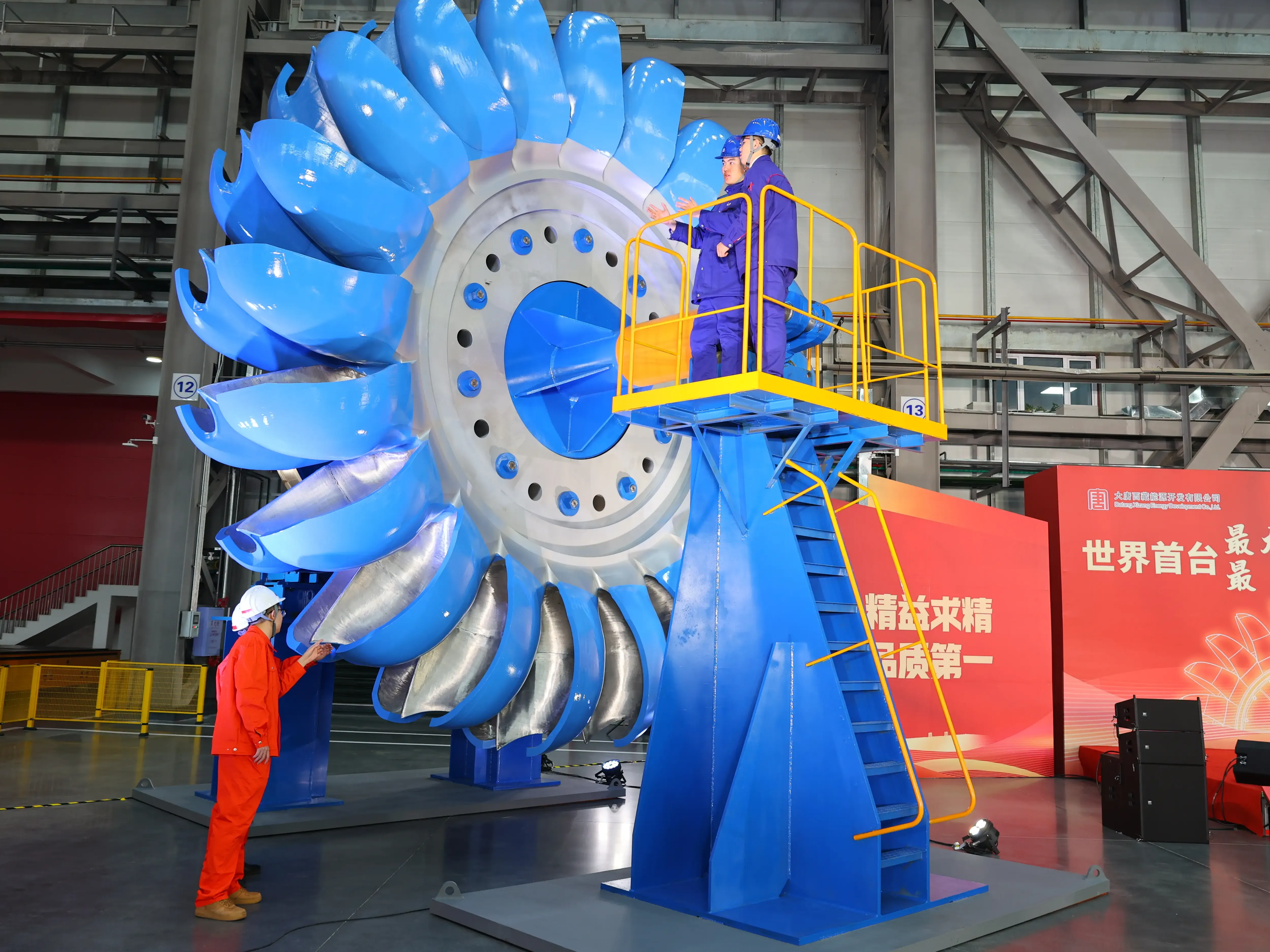

At 11 a.m. on May 20, the world's first 630°C ultra-supercritical secondary reheat generator set made of Chinese-made G115 steel was successfully hoisted at the site of the 630°C ultra-supercritical secondary reheat national power demonstration project in Yuncheng, Datang Shandong. This marks the first time that China's self-developed G115 steel has been applied in engineering.

G115® steel is a new generation of martensitic heat-resistant steel independently developed by China for more than ten years, its strength and oxidation resistance are greatly improved compared with imported steel, which can reduce the wall thickness of the pipeline by one-third and the weight by half, and is currently the only martensitic heat-resistant steel that can be used for 630~650 °C metal wall temperature in the world.

Lin Yue, commander-in-chief of the Datang Yuncheng project, introduced that the Datang Shandong Yuncheng project for the first time fully applied the domestically developed G115® steel to key parts such as the main steam pipeline, realizing the independent and controllable key core technologies, marking the construction of a complete industrial chain from material research and development, metallurgical manufacturing to equipment application in China.

As the only million-kilowatt coal-fired national power demonstration project approved during the "13th Five-Year Plan" period, the thermal efficiency of the project's units exceeded the 50% mark, and the coal consumption for power supply dropped to the lowest level in the world, achieving the four world's highest pressure, highest temperature, highest efficiency and lowest coal consumption. Yu Haiyi, the person in charge of the Datang Yuncheng project, said that after the project is put into operation, it will save 467,200 tons of standard coal and reduce carbon dioxide emissions by 1.26 million tons compared with conventional units (calculated according to the white paper "China's Energy Transition" released by the State Council on August 29, 2024), setting a new benchmark for the green transformation of the thermal power industry.

The breakthrough of the key node of G115® steel engineering application fully demonstrates the practical achievements of Datang Shandong Company in adhering to innovation-driven development and cultivating demonstration and leading advantages, and is also a landmark progress made by its "nine major events" in scientific and technological research, which not only provides key supporting materials for the construction of higher-parameter thermal power units, but also has the conditions for application in chemical engineering, coal chemical industry, fourth-generation nuclear power, new energy, solid oxide fuel cells and other fields, completely breaking the technological monopoly of developed countries in the field of high-temperature resistant metal materials In the field of key materials for power equipment, we have completed the leap from technological catch-up to international leadership.(This article is from the official website of Seetao www.seetao.com. Reprinting without permission is strictly prohibited. Please indicate Seetao.com + original link when reprinting) Seetao.com Strategy Column Editor/Sun Fengjuan

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~