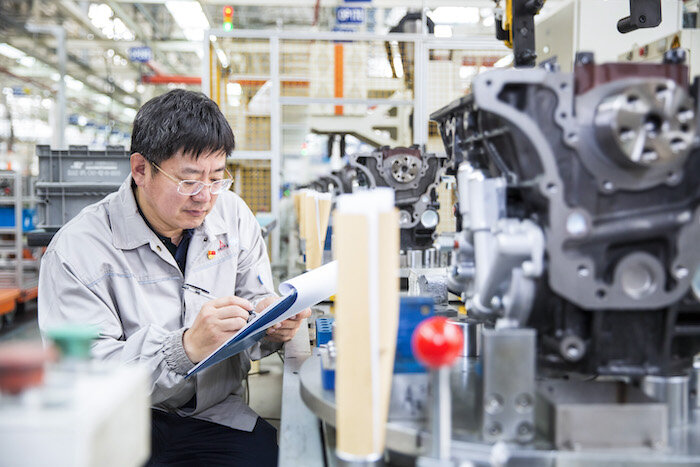

- A profound transformation about the future of manufacturing is unfolding on the land of China

This season's program visited more than ten representative enterprises and research institutions from the old industrial base in Northeast China to the manufacturing cluster in the Yangtze River Delta, from the innovation center in the Pearl River Delta to the emerging industrial park in the western region. Under the lens, what people see is not the traditional impression of machine roaring and labor-intensive production lines, but a highly automated and digital "black light factory" - even in a completely dark environment, the production line can still operate and optimize itself through the Internet of Things and artificial intelligence.

The program pays special attention to the technological innovation system behind China's intelligent manufacturing. In a number of national manufacturing innovation centers, scientific researchers are tackling key "choke" technologies such as industrial software, high-end sensors, and industrial Internet platforms. A company showcasing the research and development of core reducers for industrial robots stated that after eight years of research and development, they have finally achieved complete autonomy and controllability of this key component, with precision reaching the international leading level.

We not only solve the problem of 'existence', but also pursue 'excellence', "said an engineer involved in the intelligent production of composite materials for large aircraft on the program. By integrating artificial intelligence algorithms into the production process, their composite material placement accuracy has reached the level of 0.1 millimeters, exceeding the limit of traditional manual operations.It is worth noting that an important perspective of this season's program is how intelligent manufacturing can promote green development. In the smart energy management center of a steel enterprise, a dynamic optimization system based on big data analysis can automatically adjust energy usage strategies according to real-time production status, energy prices, and emission indicators. This system has reduced the comprehensive energy consumption of enterprises by 15%, and the annual reduction of carbon dioxide emissions is equivalent to planting 2 million trees.

"Intelligent manufacturing is not a simple replacement of machines, but the optimal allocation of resources through data drive, which is fully consistent with the connotation of high-quality development." said the specially invited commentator of the program, an academician of the CAE Member.

With the deepening of China's intelligent manufacturing, the position of China's manufacturing industry in the global value chain is undergoing profound changes. The program showcases how China's intelligent equipment serves the global market - from providing flexible production lines for European automotive factories, to offering digital transformation solutions for Southeast Asian textile enterprises, to providing remote intelligent operation and maintenance systems for African mines.

In the face of intelligent transformation, the program also focuses on the profound adjustment of talent structure. Multiple vocational colleges have showcased "learning factories" that deeply integrate with intelligent manufacturing enterprises, where students learn new skills such as robot programming, digital twin modeling, and industrial data analysis in almost real production environments. Some traditional workers have transformed into new professions such as equipment maintenance engineers and data analysts through retraining.Editor/Yang Meiling

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~