- Committed to building a modern benchmark for intelligent cold chain logistics

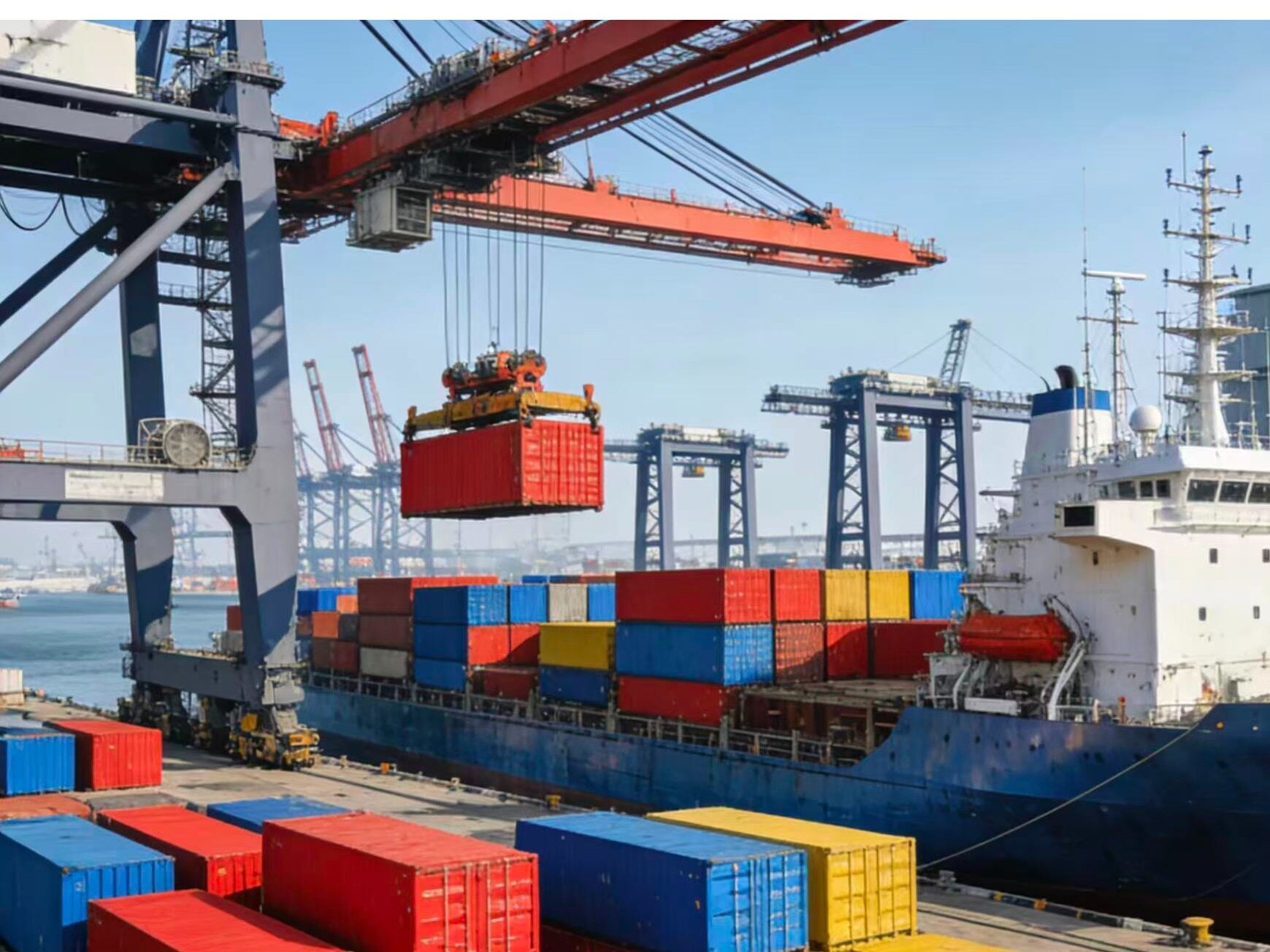

At the beginning of 2026, China Communications Construction Company, together with Shijiazhuang Jiaotou Intelligent Technology and Shijiazhuang Road and Bridge Group, successfully won the bid for the automation software and hardware procurement project of Shijiazhuang International Cold Chain Logistics Park. This is the company's first billion yuan order in the field of intelligent operations. The project is based on the core architecture of intelligent scheduling, automatic transportation, and intelligent operation and maintenance, and is committed to creating a modern benchmark for intelligent cold chain logistics.

independent innovation

The park is located in Shijiazhuang High tech Zone, positioned as a core agricultural product supply base for both flat and urgent use in the Beijing Tianjin Hebei region, a demonstration zone for innovative development of agricultural product supply chain in northern China, an international cold chain gateway in central and southern Hebei, and a centralized carrier of cold chain logistics in the provincial capital metropolitan area. The completion of the project will significantly promote high-quality development of the regional economy and set a model for digital transformation in the field of cold chain logistics. Our goal is to make the entire cold chain logistics process more efficient, transparent, and reliable through intelligent transformation, "said the project leader of China Communications Construction Company

technological breakthrough

China Communications Construction Company, relying on its core technology in the field of intelligent control, has created a comprehensive intelligent control solution for cold chain logistics parks. Its core advantages are mainly reflected in three aspects:

The company has established a smart management platform, successfully linking the entire process of warehousing and logistics, effectively solving the pain points of multi shipper management, information opacity, and operational congestion that have long plagued the industry, and achieving a significant improvement in management efficiency.

The deployment of automatic transportation systems integrates intelligent devices such as stacker cranes and unmanned handling vehicles. The R&D team has overcome technical challenges in low-temperature environments and achieved unmanned operations throughout the entire process from warehousing, storage to outbound, resulting in improved operational efficiency and storage capacity.

By integrating artificial intelligence and intelligent operation and maintenance technology, the project has built a comprehensive system for equipment health monitoring and fault prediction, promoting the transformation of operation and maintenance mode from traditional passive response to active prevention. While improving the scientificity of operation and maintenance, it has also optimized energy utilization efficiency.

industry-leading

A veteran employee who has been working in the cold chain industry for more than ten years shared his feelings: "In the past, working in a cold storage room with temperatures below minus 20 degrees not only required wearing heavy anti cold clothing, but also high-intensity physical labor." "Now, watching these automated equipment accurately complete various tasks not only improves efficiency, but also ensures the safety and health of employees. This is truly a huge progress in the industry

This project is an important milestone for the large-scale implementation of China Unicom in the field of intelligent operations. The company leader stated that in the future, they will continue to deepen their cultivation of intelligent control technology, create and output systematic, innovative, and scalable technical solutions. The company is fully committed to building a modern, intelligent, and digital smart logistics industry ecosystem, providing strong support for the transformation and upgrading of China's cold chain logistics industry.

Economic radiation

With the advancement of the project, Shijiazhuang International Cold Chain Logistics Park will become an important hub connecting the agricultural product supply chain in North China.

In the park, the tall automated three-dimensional cold storage has begun to take shape, with unmanned moving vehicles running smoothly along the established track, and intelligent stacker cranes flexibly shuttling between shelves. The entire operation process is orderly.

This project not only enhances the technological level of cold chain logistics, but also drives the development of related industrial chains and creates a large number of job opportunities.

By optimizing the efficiency of cold chain logistics, the loss of agricultural products in circulation can be effectively reduced, ensuring food safety and providing more stable support for the supply of agricultural products in the Beijing Tianjin Hebei region.

Inside the cold chain logistics park, staff are monitoring the operational status of the entire park through an intelligent control platform. The screen displays real-time working data, storage temperature, and environmental parameters of various devices, and everything is under control. In the low-temperature cold storage area of minus 25 degrees, unmanned transport vehicles are automatically driving along the planned route, accurately transporting goods to designated locations, completely replacing traditional manual handling operations. Technicians are checking the operational status of the automated stacker crane. These intelligent devices can work stably in extremely low temperature environments, greatly improving the efficiency and safety of cold chain logistics operations.

On the big screen of the intelligent management platform, various data visualizations display the real-time operation of the park. The entire process of information from goods warehousing to outbound is transparent and traceable, effectively solving the pain point of opaque information in traditional cold chain logistics. The project team is discussing the optimization plan for the equipment health monitoring system. Through artificial intelligence technology, the system can predict equipment failures in advance, achieving a shift from passive maintenance to proactive prevention in operation and maintenance mode. In the future, China Unicom will continue to be driven by technological innovation, promote the application of intelligent control in more fields, and contribute to the upgrading of China's logistics industry and the development of the digital economy.Editor/Yang Meiling

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~