- Academician Zhang Fucheng's team breaks through multiple core steel and environmental protection technologies

On February 6, 2026, Academician Zhang Fucheng was carefully examining a set of latest mechanical data of steel in the laboratory of North China University of Science and Technology. When it comes to the team's technological innovation and achievement transformation during the 14th Five Year Plan period, this materials scientist's eyes sparkle with pride. The team led by him has deeply integrated the unique concept of simplification - that is, pursuing material performance limits through minimalist alloy design and precise process control - into scientific research and development, and has achieved a series of breakthrough results in key steel materials and green smelting technology, effectively supporting the transformation and upgrading of major national projects and industries.

Mechanical metallurgy, turning stone into gold, creating miracles

The team has applied the core technology of mechanics and metallurgy to the research and development of materials in extreme environments, achieving remarkable results. In response to the extreme requirements of the epic project of the Sichuan Tibet Railway for special steel for turnouts and crossings, the team has successfully developed a specialized steel that can resist strong corrosion, large temperature differences, strong ultraviolet radiation, and active crustal environments. With its long service life and high reliability, it ensures railway safety and significantly reduces the cost of the entire life cycle. In the research and development of high-end steel, the team has achieved a revolutionary breakthrough: using only 5wt% of alloy elements, a 3GPa steel with a strength of up to 3GPa, elongation of 10%, and fracture toughness of 60MPanp ¹/² has been prepared, and its strength plasticity combination has reached the highest level reported in the world; A ultra-high hardness and toughness bearing steel with a hardness of HV900 and toughness of 50J has been developed with an alloy content as low as 2.5wt%, which is internationally leading in performance. In addition, through mechanical metallurgy technology, the team has achieved performance transitions in a series of steel grades, such as developing high manganese steel that meets the requirements of ultra-low temperature environments ranging from minus 196 to 254 degrees Celsius for LNG and liquid hydrogen storage tanks; Upgrade traditional NM300 and NM360 wear-resistant steel to NM360 and NM400 levels, with an increase in wear resistance of over 30%; Even the performance of widely used Q235 steel has been upgraded to the Q355 level, allowing ordinary 45 steel to achieve alloy steel performance and truly turning stone into gold.

Molten salt electrolysis, turning waste into treasure and opening up new paths

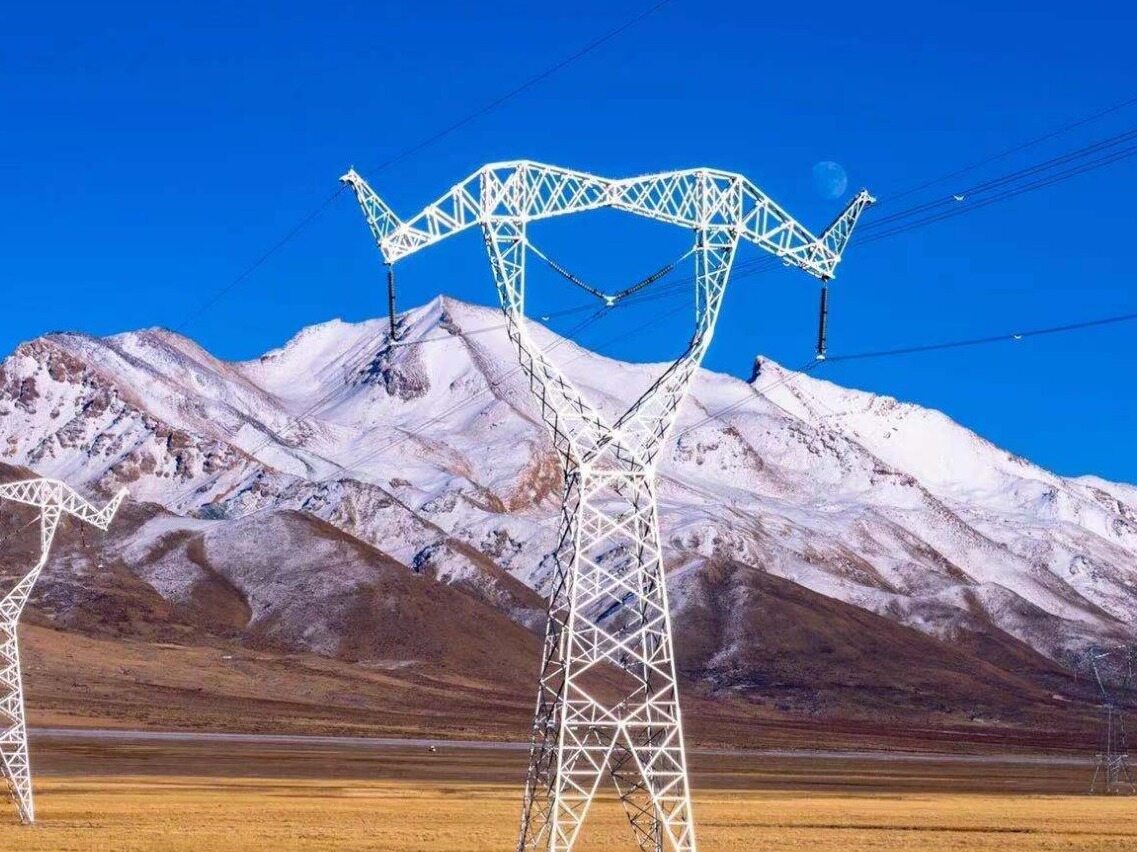

In the field of green smelting, the team's independently developed low-temperature molten salt electrolysis technology has achieved a disruptive breakthrough. This technology can not only efficiently process iron ore, but also digest the huge environmental burden known as red pollution - industrial solid waste such as red mud. It can convert it into high-purity iron in one step and simultaneously enrich and recover valuable elements such as titanium, aluminum, and silicon, achieving the goal of drying up and turning waste into treasure. At present, this technology has applied for patent protection in major economies around the world and is steadily moving from successful ton scale pilot testing to the 10 ton scale industrialization pilot stage. Academician Zhang Fucheng specifically pointed out that this technology path is extremely simple and does not require traditional carbon based reducing agents. If all green electricity such as wind power, photovoltaic power, hydropower or nuclear power can be used, it is expected to achieve true zero carbon smelting and open up a new path for the green revolution of the steel industry. Keywords: Feature News Information, Feature News Network

Process governance, reducing costs and increasing efficiency to protect the blue sky

In response to the common problem of carbon monoxide emission reduction faced by steel enterprises, the team has developed a low-cost and high-efficiency process management technology. This technology abandons the expensive and complex terminal catalytic treatment route, and instead starts with the control of smelting source ingredients and process chemical reactions, achieving stable and compliant emissions of carbon monoxide through optimizing the process essence. This technology has been successfully implemented and applied in multiple steel enterprises in Xinjiang, Hebei and other places. It not only solves environmental problems at a significantly lower cost than traditional end-point treatment, but also improves the economic efficiency of the production process, achieving a win-win situation between environmental and economic benefits, and providing innovative and practical solutions for ultra-low emissions in the steel industry.Editor/Gao Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~