- With the installation of the last methanol C tank in place, good news came from Yumen Economic Development Zone in Gansu Province

In Yumen, Gansu, a land once famous for oil, there is now an industrial revolution about "new materials". Recently, with the installation of the last methanol C tank body in place, the installation of non-standard equipment for the liquid storage and transportation facilities of the Gansu Juhua High Performance Silicon Fluoride New Material Integration Project, which was constructed by China National Chemical Engineering Corporation's China Fifth Ring Engineering Co., Ltd. EPC general contracting, has been announced as completed. This not only means that the project's process installation is about to be fully launched, but also marks the official establishment of the "giant" project with a total investment of 41 billion yuan in the chemical industrial park in the old city area of Yumen Economic Development Zone, pressing the "fast forward button" to reshape the pattern of the high-end materials industry chain in Northwest China.

Overcoming difficulties and building a solid defense line for quality and safety

As a key storage and transportation unit of the project, liquid storage and transportation facilities have dense containers and diverse media, making construction organization extremely difficult. Faced with multiple challenges such as frequent extreme weather and tight construction schedules, the project team has implemented precise strategies and targeted attacks. They have specially established a construction management team to strictly implement high standards for engineering construction and strict requirements for quality control. During the installation process, the team strictly implements key aspects such as raw material inspection, precise control of equipment dimensions, fine construction of wall panel anti-corrosion and rust removal, and closed-loop control of welding quality, fully implementing safety production regulations and standardized operating procedures. By strengthening specialized safety technology disclosure and conducting regular on-site inspections, the project team has successfully established a quality and safety defense line, ensuring the smooth completion of the installation of the tank body.

Closed loop of the entire chain, creating an international first-class industrial base

This project is a key project in Gansu Province, with a total investment of 41 billion yuan and will be constructed in three phases. Among them, the total investment of the first phase of the project is about 20 billion yuan. The project has established a closed loop of the entire industry chain of "silicon fluorine new materials terminal applications" through integrated upstream and downstream layout, aiming to create a leading domestic and world-class industrial base. As the head office of the project, China Wuhuan Engineering Co., Ltd. has also undertaken the EPC engineering of project sections six and seven, covering the construction of core units such as public auxiliary engineering and water treatment equipment. After the completion of the project, it will greatly promote the high-quality development of regional economy and industrial transformation and upgrading, becoming an important growth pole for the new material industry in Gansu and even the northwest region.

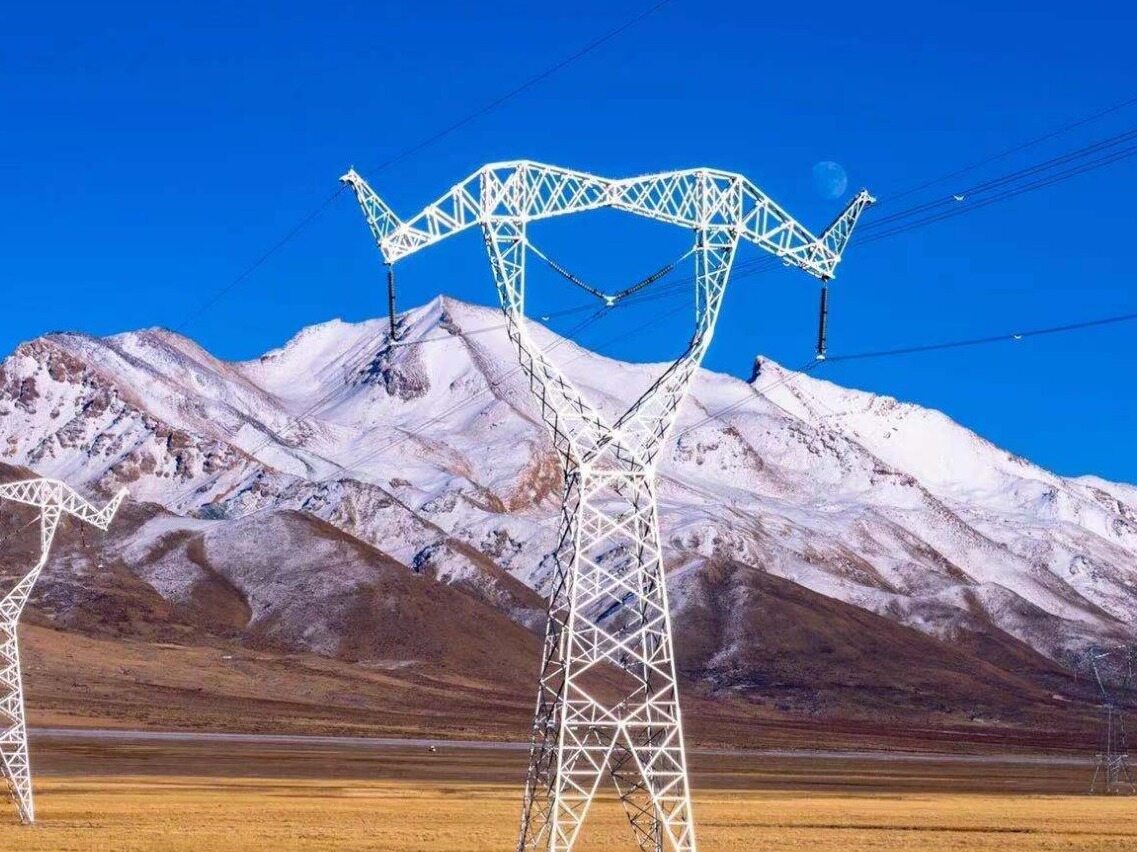

Green empowerment, matched with photovoltaic energy storage system

It is worth mentioning that this project not only focuses on new chemical materials, but also deeply integrates the concept of green energy. The project is equipped with a 1.95GW photovoltaic power station and a 3.9GWh energy storage system, with an expected annual power generation of 6000GWh. This green energy support not only provides clean power guarantee for the project itself, reduces operating costs, but also reflects the forward-looking layout of the project in promoting green and low-carbon development, providing a "Gansu sample" for the sustainable development of the chemical industry.Editor/Yang Meiling

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~