- The shipment and installation of the first caisson marked the beginning of the construction phase of the Beibu Gulf Port Wharf

Recently, the 4,000-ton semi-submersible barge slowly left the wharf and sailed to the Dalanping operation area of Qinzhou Port on the opposite bank. It is carrying the first caisson of the 200,000-ton-class automated container terminal at Qinzhou Port. It will be consigned to the site of Berths 9 and 10 in Dalanpingnan Operation Area of Qinzhou Port, 6.5 kilometers away, and the installation will be completed within 24 hours.

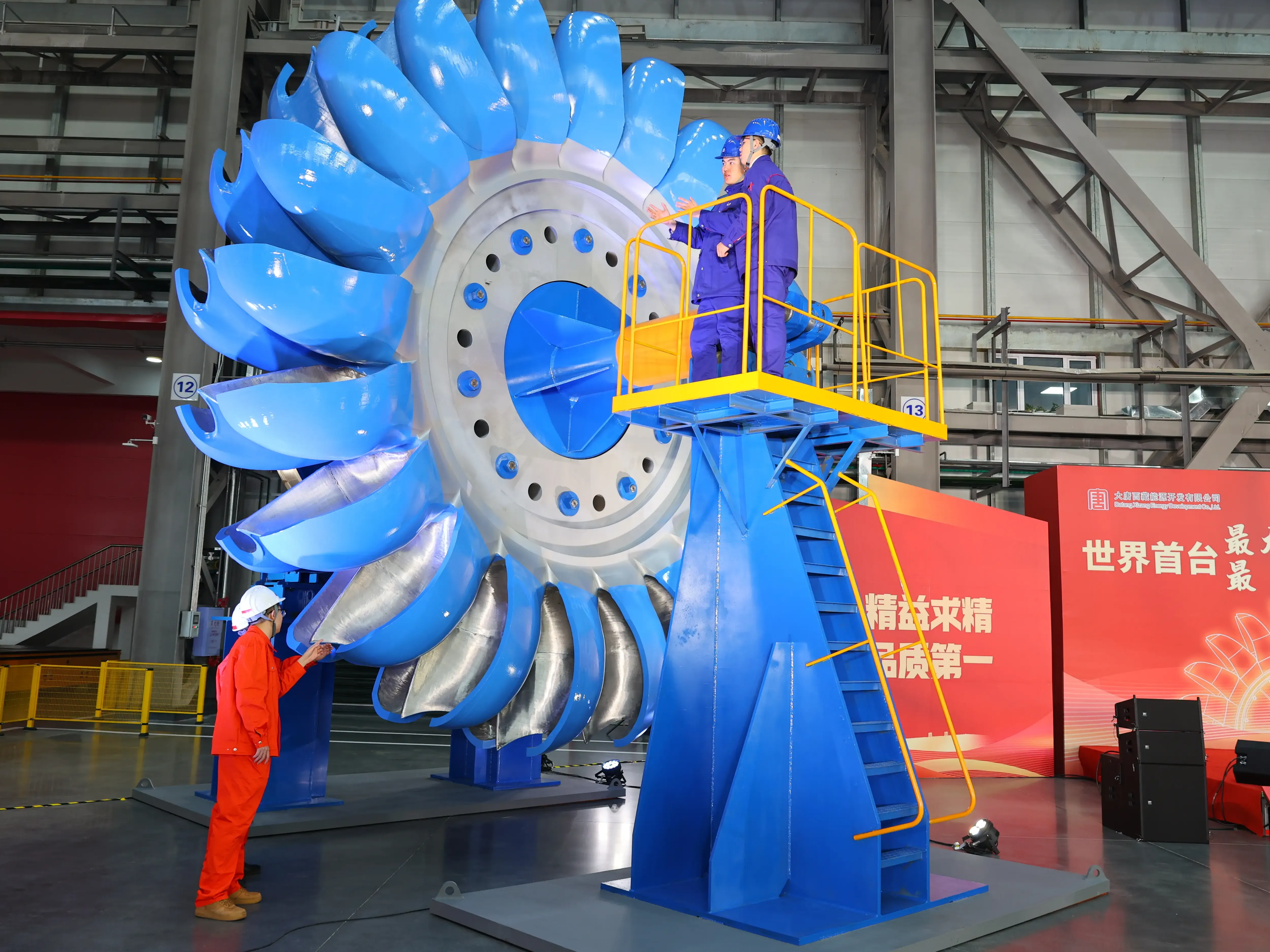

The 3650-ton caisson shipped this time is 23.9 meters long, 15.8 meters wide, and 21 meters high, which is equivalent to an 8-storey building. It is a veritable maritime "big Mac" and has the largest volume in the Beibu Gulf port.

The 200,000-ton-class automated container terminal berth project of Qinzhou Port has a designed annual throughput of 1.6 million TEUs and a total investment of approximately 4.2 billion yuan. Since the project started on August 30 last year, it took only two months to complete the construction of the first modern large-scale caisson prefabrication plant in Beibu Gulf with an area of 104,500 square meters. The first stage of prefabrication conditions is available in 50 days, and the production capacity in 100 days is 100%, creating a new record of construction speed. As of March 26, the project has completed 33 sections of caisson prefabrication, 4 million cubic meters of wharf foundation troughs and harbor basins have been dredged, 80% of the dredging of the dock basins have been completed, 65% of the wharf foundation troughs have been dredged, and 22% of the caisson prefabrication completed. .

In the first year of the "14th Five-Year Plan", Beibu Gulf Port Group, as the main force in the construction of the new western land and sea channel and the Beibu Gulf international hub seaport, aims to build a world-class automated container terminal and create the "100-year quality project of the Ministry of Transport". It has organized design and construction units to hold dozens of research seminars on key issues in prefabrication of caissons, and completed 11 technical development projects and application of innovative results. In the manufacturing process, it is dedicated to realize the automation and intelligence of the whole process of component processing, production, shipment, etc., including the integral hoisting of steel bars, automatic welding of steel bars, the transportation technology of the caisson hydraulic jacking trolley, and the automatic spray maintenance system. The technological achievements have filled the blanks in the related technical fields of Beibu Gulf port construction and injected innovation-driven accelerators into the construction of automated terminals. Editor/Bao Hongying

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~