- Chu Neng New Energy has signed a cooperation agreement worth over 10 billion yuan between Shanshan Technology and Xinzhoubang

In 2025, the lithium battery industry will gradually emerge from a three-year downward cycle and usher in recovery and restructuring. With the easing of price competition, global layout, diversified product structure, and financial and technological strength are becoming the new focus of industry competition, promoting the accelerated upgrading of multiple industrial chain links.

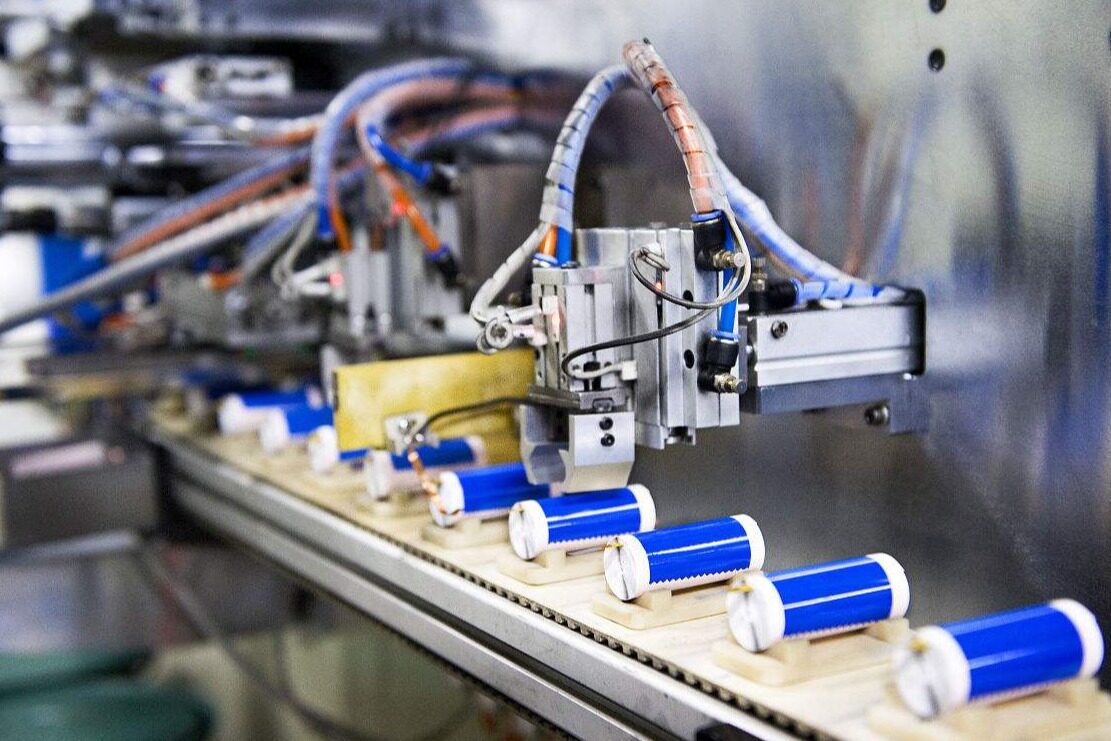

In this context, the construction of Chu Neng's new energy supply chain system has recently shown an explosive trend. Since the beginning of this year, the company has been intensively locking in core raw materials such as positive electrode materials, structural components, and copper foil through the "long-term cooperation model", and continuously improving its supply network layout.

Within a week, Chu Neng New Energy signed two major strategic cooperation agreements with a total amount exceeding 10 billion yuan. On August 15th, Chu Energy and Shanshan Technology reached a procurement agreement for negative electrode materials at Chu Energy's global headquarters, with a cooperation scale of over 10 billion yuan. Both parties also plan to carry out joint development in two major areas: high and low temperature performance, high rate fast charging, high safety negative electrode materials, and high-capacity and long cycle negative electrodes for energy storage batteries. Following closely behind, on August 18th, Chu Neng signed a strategic cooperation agreement on electrolyte with Xinzhoubang. Xinzhoubang will rely on its vertically integrated supply chain and global intelligent manufacturing base to customize high safety, long-life, and low impedance green electrolyte solutions for Chu Energy, helping its global battery projects smoothly advance.

These two collaborations are important measures for Chu Energy New Energy to strengthen supply chain integration and deepen industrial chain collaboration. The aim is to achieve resource complementarity and technological innovation through strong alliances, which not only significantly enhances Chu Energy's competitiveness in the lithium battery market, but also effectively promotes the deep integration of the entire new energy chain, injecting new impetus into the high-quality development of the industry.

From the perspective of cooperation content, Chu Neng New Energy is focusing on breakthroughs in battery performance, with a focus on high safety, long cycle, and high-performance indicators. As a key component that determines the energy density, power density, cycle life, and safety of lithium batteries, the performance improvement of negative electrode materials has become a common concern in the industry. At present, mainstream carbon based materials are unable to fully meet the higher performance requirements of terminal applications, and developing new negative electrode systems has become an urgent task.

The current upgrade of negative electrode materials mainly revolves around two paths: one is to improve the lithium storage capacity of carbon based materials through material innovation and structural design optimization; The second is to develop non carbon based materials with better performance, such as silicon-based negative electrodes and lithium metal negative electrodes. Regardless of the direction, the iteration of negative electrode materials will bring room for profit margin improvement to enterprises and is expected to achieve a "simultaneous increase in quantity and price".

Reducing impedance is one of the key factors in improving battery performance in terms of electrolyte. Lithium ions are subject to various resistance factors such as solvent friction and ion interactions during migration, while low impedance electrolytes can significantly accelerate ion transport speed, thereby supporting faster charging and higher rate discharge. For example, using low viscosity solvents (such as dimethyl carbonate and methyl ethyl carbonate) and new lithium salts (such as lithium difluorosulfonyl imide) can effectively reduce migration resistance and improve fast charging performance. Research has shown that ternary solvent systems can maintain over 80% of the battery's capacity even at high 3C rates.

Overall, by establishing deep cooperation with material companies, Chu Neng New Energy not only enhances its ability to cope with fluctuations in raw material prices, but also continuously optimizes the core performance of batteries through collaborative research and development, consolidating its competitive position in the global new energy battery market. (This article is from the official website of Jian Dao www.seetao.com. Reproduction without permission is prohibited, otherwise it will be prosecuted. Please indicate Jian Dao website+original link when reprinting.) Jian Dao website new energy column editor/Yang Beihua

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~