- Jiang accelerates the construction of the national water network backbone for this project

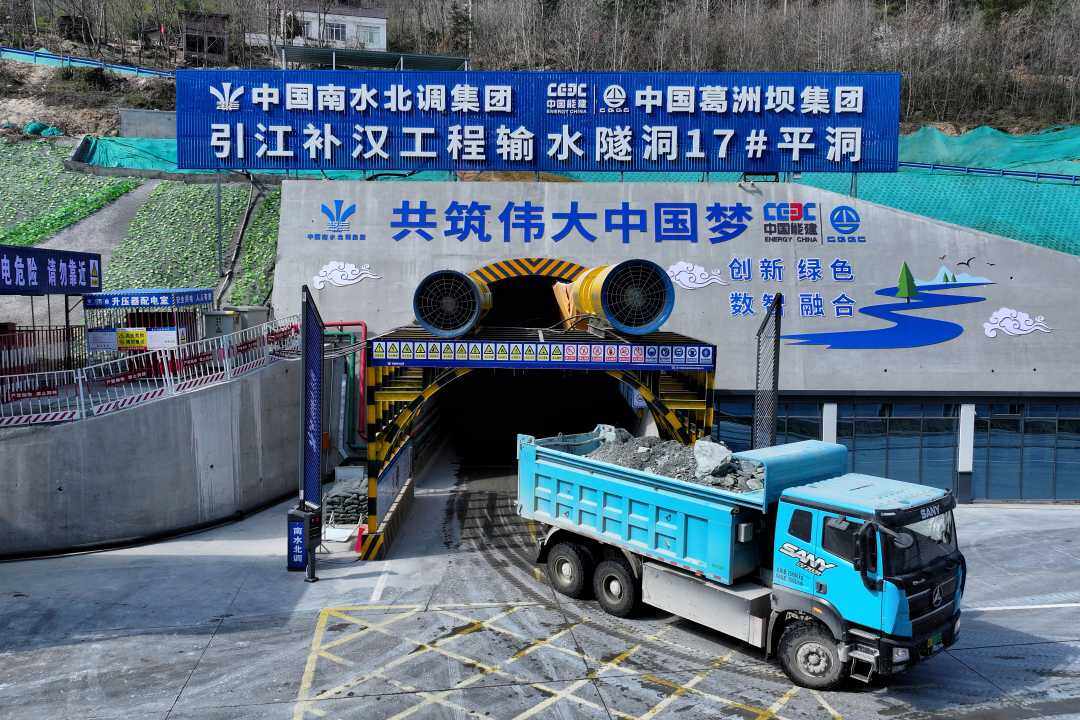

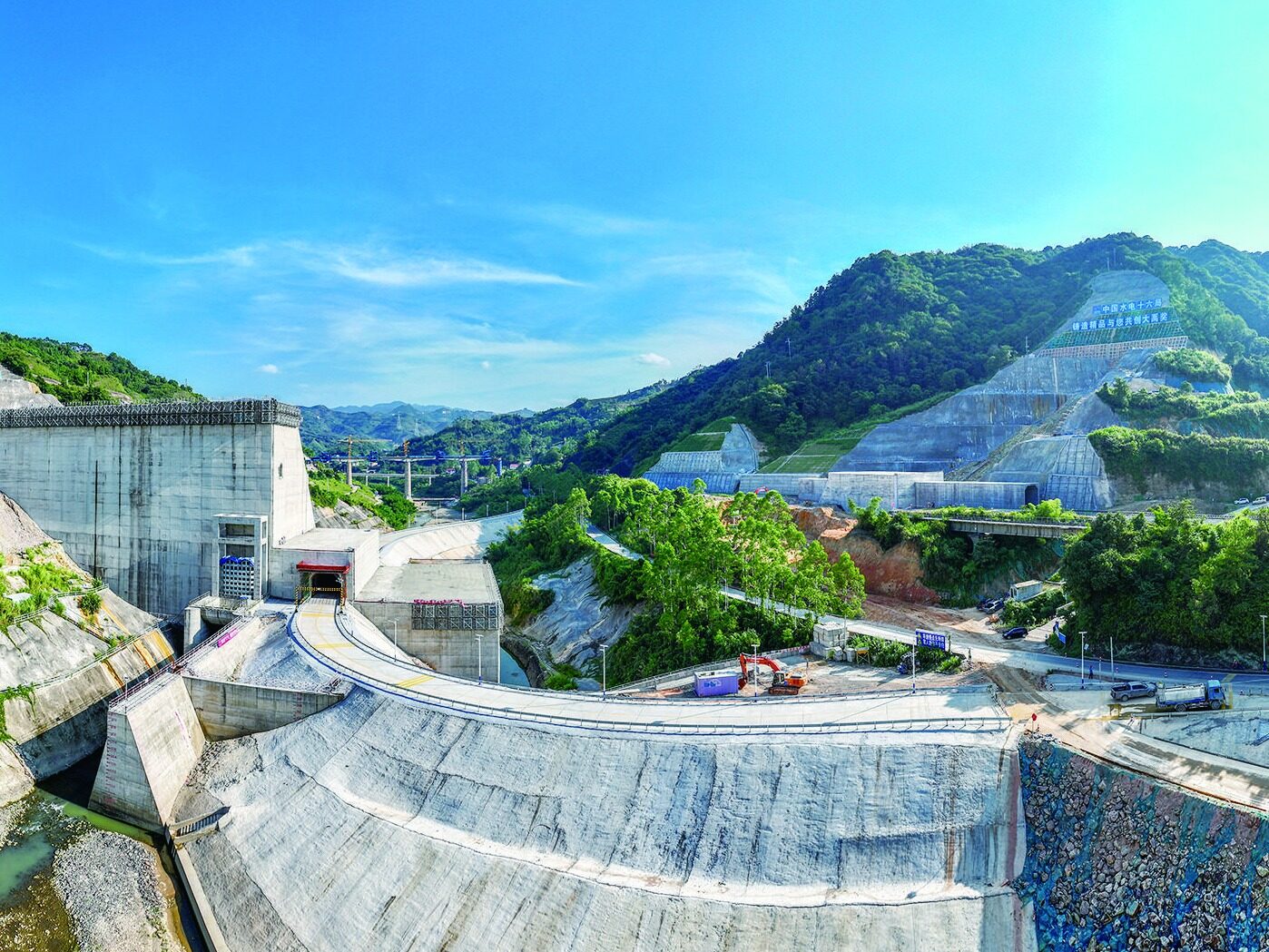

As the first project to commence in the follow-up of the South to North Water Diversion Project and a major water conservancy infrastructure during the 14th Five Year Plan period of China, the Baokang section of the Yangtze River Diversion Project is accelerating excavation under complex geological conditions. As of now, the main tunnel section has completed 2359 meters, accounting for 3.3% of the total length, with a cumulative investment exceeding 2.3 billion yuan. Among them, the civil engineering section 6 constructed by China Railway 12th Bureau has broken through world-class construction difficulties with innovative technology and become a benchmark for the entire line.

The geological challenges of the third, third, and third year are unprecedented

The total length of the water conveyance tunnel in Civil Engineering Section 6 is 18.65 kilometers, with TBM excavation section accounting for 60%. This area combines high ground stress (with a maximum stress of 35MPa), high water pressure (with a maximum head of 110 meters), and high rock strength (with a uniaxial compressive strength exceeding 200MPa), compounded by risks such as fault fracture zones, sudden water surges, and large deformations in soft rocks. It is known as an underground engineering museum by experts. The Baokang section alone crosses 12 regional fault zones, with a maximum daily water inflow of 30000 cubic meters, making the construction difficulty world-class.

China's intelligent manufacturing solves world problems

The project team collaborated with equipment manufacturers to customize the "Jianghan Development" TBM. Through technological innovations such as eccentric design of the cutterhead shield and dual speed reducer, the equipment's adaptability to complex geological formations was improved by 40%. Innovatively establish a card machine warning and evaluation system, integrating geological radar, microseismic monitoring and other means to achieve risk prediction 72 hours in advance. In construction management, a three-level progress control system consisting of project department, work area, and team will be established. The 18.65 kilometer tunnel will be divided into 28 work units, and a seamless process connection will be ensured through daily meetings, weekly analysis, and monthly assessment mechanisms.

Double hole advancement refresh progress bar

At present, the 12th level tunnel is constructed using a combination of drilling and blasting method and TBM excavation, and has been completed ahead of schedule; The TBM excavation of the main tunnel reached 1156 meters and is expected to exceed 2200 meters by the end of the year. The construction of the 13th flat tunnel using the drilling and blasting method has also been completed, with the main tunnel excavated for 1448 meters and expected to reach 2100 meters by the end of the year. This underground Yangtze River, with an average annual water transfer of 3.9 billion cubic meters, is extending towards the Han River at a speed of 10 meters per day, injecting strong momentum into the construction of the main framework of the national water network. Editor/Cheng Liting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~