- This project will achieve complete localization of independent intellectual property rights throughout the entire industry chain

- Zhala Hydropower Station is equipped with 2 sets of 500 MW level impulse turbine generator units with a single unit capacity

Recently, Harbin Electric Machinery Plant of Harbin Electric Power Group won the bid for a 500 MW impulse hydropower unit and its auxiliary equipment in Zara, which has the largest single unit capacity in the world. This will effectively improve the overall level of China's impulse hydropower units, improve Sinohydro's hydropower development capacity, realize the autonomy and controllability of key core technologies of hydropower equipment, and play a leading and exemplary role.

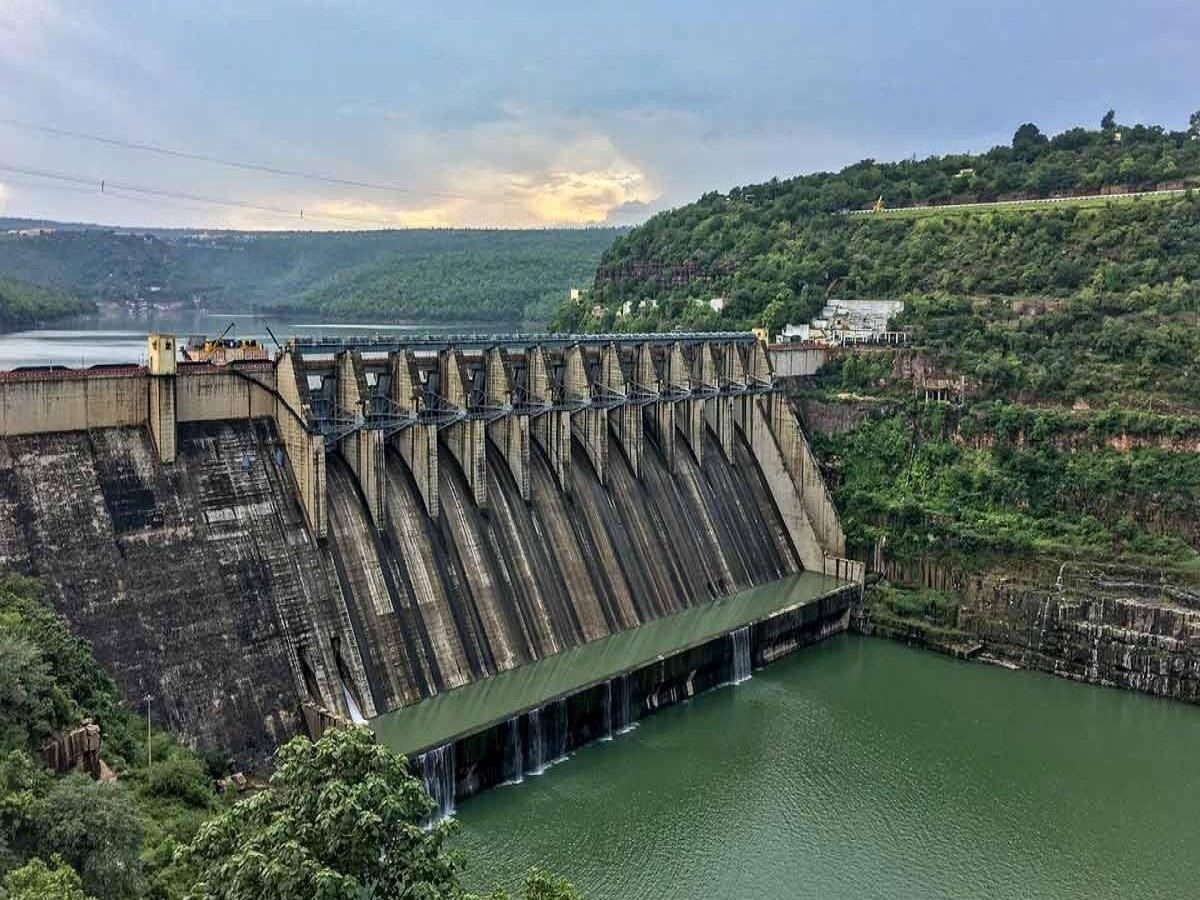

Zala Hydropower Station is developed and constructed by China Datang Corporation. It is equipped with two 500 MW impulse water turbine generator units. The power station has engineering and technical characteristics of high head, large capacity, impulse type, deep shaft, etc.

This project has been selected as the first major technical equipment project in the energy field of the National Energy Administration, which will achieve complete localization of independent intellectual property rights throughout the entire industry chain and improve China's research and development and manufacturing level in the field of giant impact hydroelectric units.

Under the unified coordination and command of China Datang Corporation, Harbin Electric Machinery Co., Ltd. attaches great importance to the research and development of Zara impact units, has completed a number of key scientific and technological breakthroughs, and has broken through many technical problems.

In terms of hydraulic research and development, multiple runner hydraulic development and model tests have been completed around the Zhala project. The model runner has excellent performance, a wide range of high efficiency areas under various nozzle combinations, efficient and stable output, and can achieve long-term continuous and stable operation under low load conditions, laying a solid foundation for ensuring efficient and stable operation of the unit.

In terms of tackling key problems of runner forgings, Harbin Electric Machinery Co., Ltd. and China First Heavy Industries Group Co., Ltd. jointly tackled key problems, and completed trial production, process validation and application performance evaluation of several ingot forgings with high quality, as well as simulation and simulation of super large die forging buckets, breaking through the key manufacturing technical problems of super large Martensitic stainless steel runner forgings. Editor/Xie Li

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~