- China and Algeria jointly build Algeria's heavy-duty mining railway, with a total investment of 5 billion US dollars

Between the vast deserts and plateaus of North Africa, a steel giant dragon is gradually taking shape. In July of this year, the pilot section of a 950 kilometer heavy-duty mining railway in western Algeria, connecting the reserves of up to 3.5 billion tons at the Galajebilet iron mine, was successfully laid and completed, marking a key progress in this massive infrastructure project with a total investment of over 5 billion US dollars. The project is jointly constructed by a consortium consisting of China Railway Construction Corporation Limited and Algerian local giant COSIDER Group. The entire line adopts Chinese technology and standards, and actively integrates local forces during the construction process, exploring a new path of sustainable international cooperation.

The Steel Corridor in the Desert

The western part of Algeria is rich in mineral resources, especially iron ore and phosphate reserves, which are extremely considerable. However, for a long time, the backward transportation conditions have seriously restricted the development of resources. This newly built heavy-duty railway is designed to have an annual capacity of 50 million tons and will become an important economic lifeline connecting inland mining areas with coastal smelting industrial parks and ports in the future.

Railway construction not only challenges its length, but also faces complex terrain and extreme environments - the line crosses the edge of the Sahara Desert, and high temperatures, strong sandstorms, and huge day night temperature differences place extremely high demands on the durability of steel rails and the stability of signal systems. China Railway Construction Corporation Limited relies on mature heavy-duty railway technology, introduces a power distributed traction system suitable for steep slopes, as well as an intelligent signal and dispatch control system, to ensure the safe and stable operation of railways in harsh environments.

The win-win logic behind "joint construction"

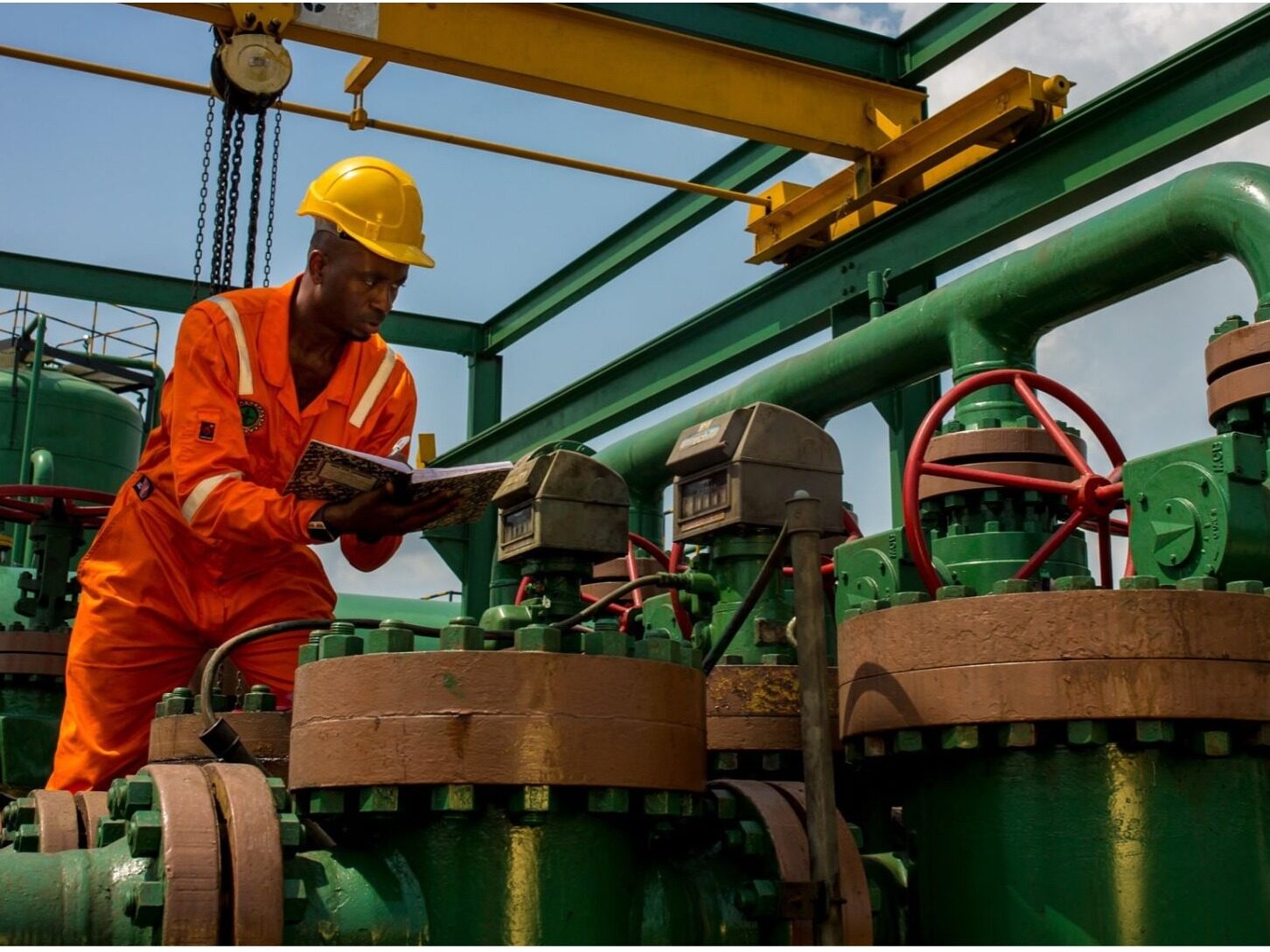

Different from the previous model of Chinese enterprises undertaking general contracting in Africa, the Algerian government has explicitly requested that China Railway Construction Corporation Limited and local enterprise COSIDER Group jointly implement it. As the largest engineering construction enterprise in Algeria, COSIDER Group has rich experience in civil construction, but there are still shortcomings in the overall management and technical integration of large-scale railway projects. This cooperation model not only fully leverages China's advantages in core technology, project management, and equipment supply, but also promotes the deep participation of local enterprises, achieving capacity building and experience inheritance.

From 'labor export' to 'technological symbiosis'

In the past, Chinese companies often faced controversy in overseas projects due to "bringing their own workers and closed management", which ensured efficiency but made it difficult to truly benefit the host country. The Algerian government has put forward a clear requirement: core technologies and standards can be entrusted to the Chinese side, but work that can be localized and implemented must be given priority to Algerian enterprises. This policy has prompted Chinese companies to adjust their strategies, gradually shifting from relying on domestic labor exports to technology exports and localized cooperation.

In Algeria, China Railway Construction Corporation Limited took the initiative to establish a joint venture with local railway related enterprises and arranged for Algerian employees to attend system technology training in China. Although this long-term investment increases initial management costs, it has won a more stable government enterprise relationship and a more sustainable operating environment for the enterprise.

The entire railway line is constructed according to Chinese standards. An official from the Algerian Ministry of Transport stated that "Chinese standards have shown excellent cost-effectiveness and adaptability, and China is willing to transfer some key technologies, which is crucial for Algeria." In fact, this railway is not only a transportation channel, but also a key measure for Algeria to get rid of its dependence on oil and gas exports and build a national industrial corridor. It is also another milestone for China's railway system technology to root in Africa. After the full line is opened to traffic, it is expected to not only significantly improve the ore transportation capacity and steel export competitiveness, but also drive the urbanization process and the rise of supporting industries along the line, becoming a demonstrative "railway economic belt" in North Africa. (This article is from the official website www.seetao.com of Jian Dao. Reproduction without permission is prohibited, otherwise it will be prosecuted. Please indicate Jian Dao website+original link when reprinting.) Jian Dao website infrastructure engineering column editor/Yang Beihua

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~