- Building a fully integrated digital and intelligent industrial ecosystem to improve quality and efficiency

- China Railway Industrial Innovation Technology Research and Development, Promoting Industrial Transformation through Digital Intelligence Upgrade

The 14th Five Year Plan period is the first five years for China to embark on a new journey of comprehensively building a socialist modernized country and advancing towards the second centenary goal. It is also an important period for China Railway Industry to shoulder its mission and forge ahead as the main force in promoting the high-end, intelligent, and green development of China's manufacturing industry. Over the past five years, China Railway Industry has been deeply implementing the important instructions of the "Three Transformations", embracing the "greatness of the country", supporting major projects, and leading green transformation. Starting today, China Railway Industry's official WeChat account will open a column titled "Hardcore 14th Five Year Plan" to review the extraordinary five years we have walked together in various forms.

During the 14th Five Year Plan period, China Railway Industry Corporation (CRCC) innovated technology research and development, promoted industrial transformation through digital upgrading, and demonstrated its capabilities in scenarios such as intelligent manufacturing of steel structures for cross sea bridges, excavation of high-altitude railway tunnels, integration of urban rail transit equipment, and integrated construction of major overseas projects. Not only did it break multiple industry technology records, but it also established a full chain digital industrial ecosystem, improving the quality and efficiency of enterprise development.

During the 14th Five Year Plan period, China Railway Industry Corporation (CRCC) innovated technology research and development, promoted industrial transformation through digital upgrading, and demonstrated its capabilities in scenarios such as intelligent manufacturing of steel structures for cross sea bridges, excavation of high-altitude railway tunnels, integration of urban rail transit equipment, and integrated construction of major overseas projects. Not only did it break multiple industry technology records, but it also established a full chain digital industrial ecosystem, improving the quality and efficiency of enterprise development.

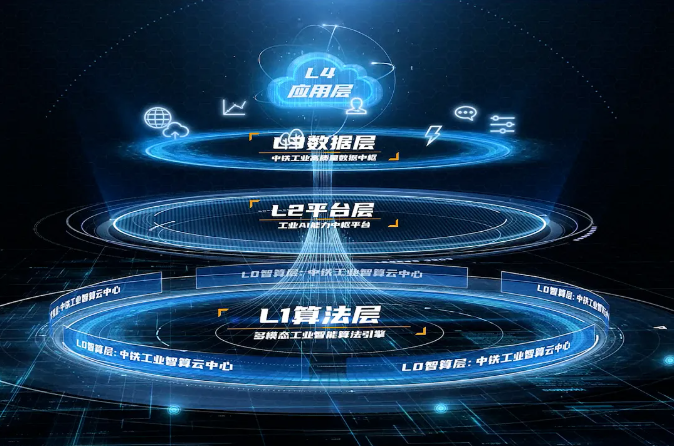

This model is a core platform created by China Railway Industry to respond to the national digital and intelligent strategy and promote the industry's transformation towards high-end. As an "industry level specialized big model" that deeply integrates the mechanism, process experience, and data characteristics of the engineering equipment manufacturing industry, it relies on the five layer technical foundation of "computing power algorithm data platform application", adheres to the principle of "solving core pain points, building scenario closed loops, and creating practical value", constructs a "1+4+N" big model capability system, and integrates key functions such as industrial intelligent computing cloud center, multimodal intelligent algorithm engine, AI capability center, high-quality data center, and enterprise digital image. It has become a "technology center" and "knowledge carrier" that empowers the intelligent upgrading of the entire manufacturing industry, creating an integrated AI service platform with "technology foundation and scenario king", and comprehensively promoting enterprises to move from "experience driven" to "enterprise digital image". The new stage of 'model driven'.

Precision Ace in Welding Field

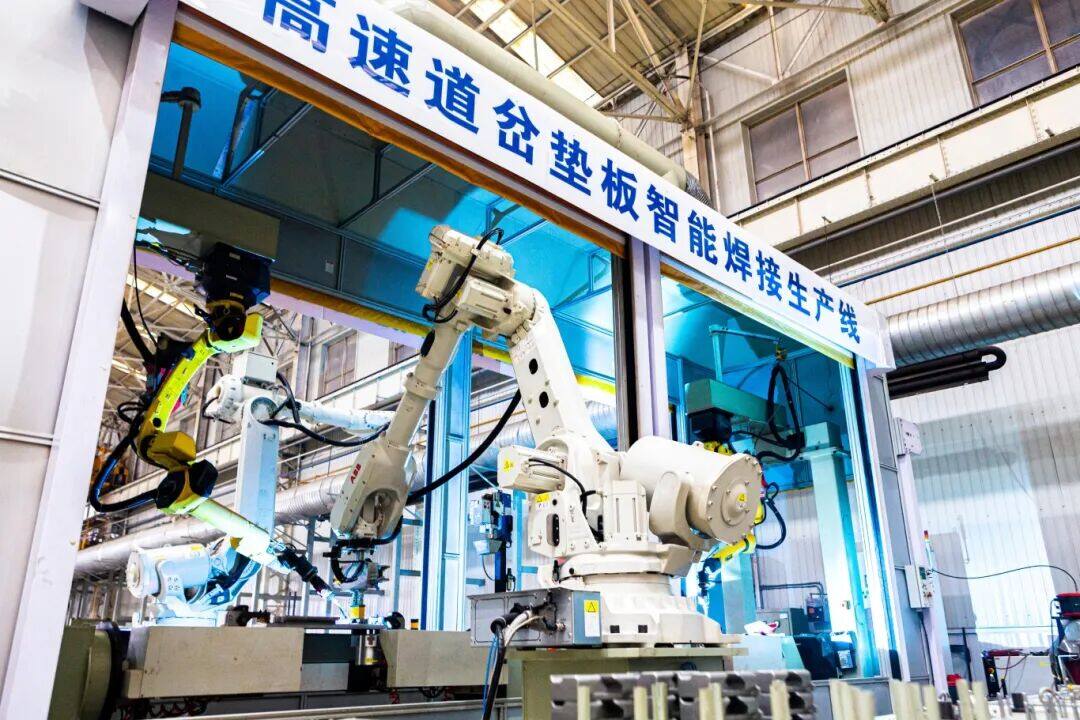

China Railway Industry Corporation (CRCC) has built a high-speed turnout pad welding production line with technological innovation as the core and digital upgrading as the lever. By deeply integrating advanced technologies such as handling industrial robots, welding industrial robots, material conveying systems, quality automatic detection systems, and binocular recognition systems, we have achieved excellent results with a 100% pass rate for welding quality inspection, significantly reducing the labor intensity of workers and effectively optimizing their working environment.

China Railway Industry Corporation (CRCC) has built a high-speed turnout pad welding production line with technological innovation as the core and digital upgrading as the lever. By deeply integrating advanced technologies such as handling industrial robots, welding industrial robots, material conveying systems, quality automatic detection systems, and binocular recognition systems, we have achieved excellent results with a 100% pass rate for welding quality inspection, significantly reducing the labor intensity of workers and effectively optimizing their working environment.

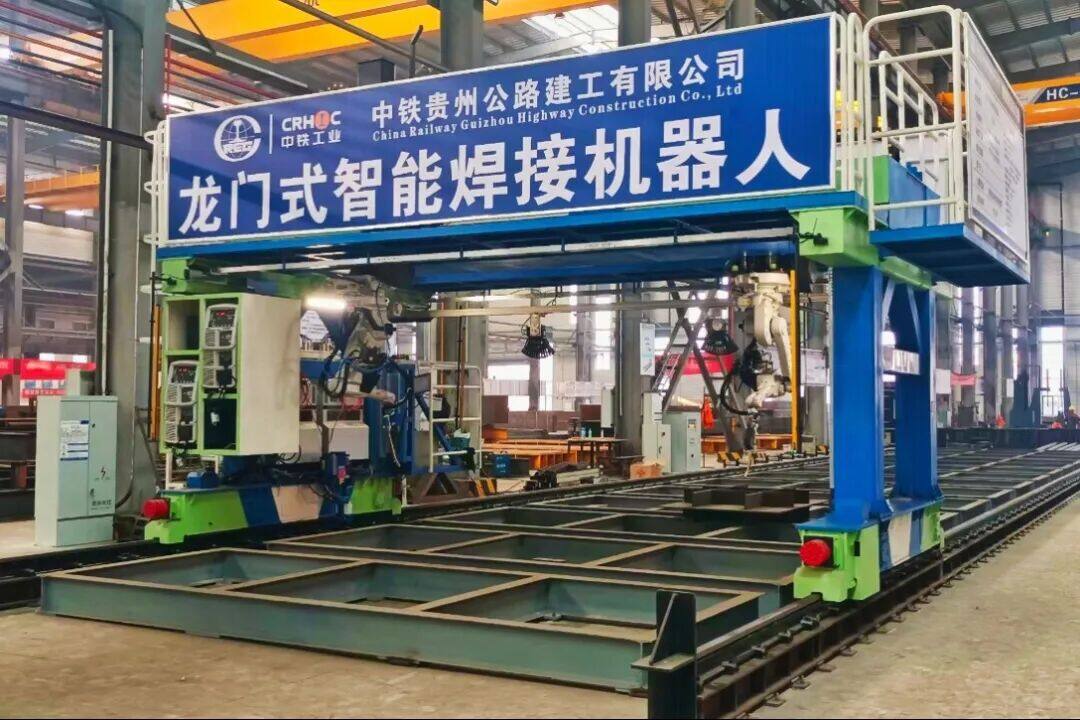

The robot consists of a precision three-axis gantry motion mechanism, a six axis welding robot, and ground ancillary equipment such as lasers and water coolers, innovatively integrating laser welding and arc welding technology. By using high-precision motion control to guide the precise positioning of the welding head, laser achieves strong penetration deep welding, and electric arc welding fills the weld seam to ensure connection quality. The two work together to increase welding speed several times faster than traditional methods, and the heat input is concentrated, greatly reducing workpiece deformation and synchronously improving weld strength and aesthetics

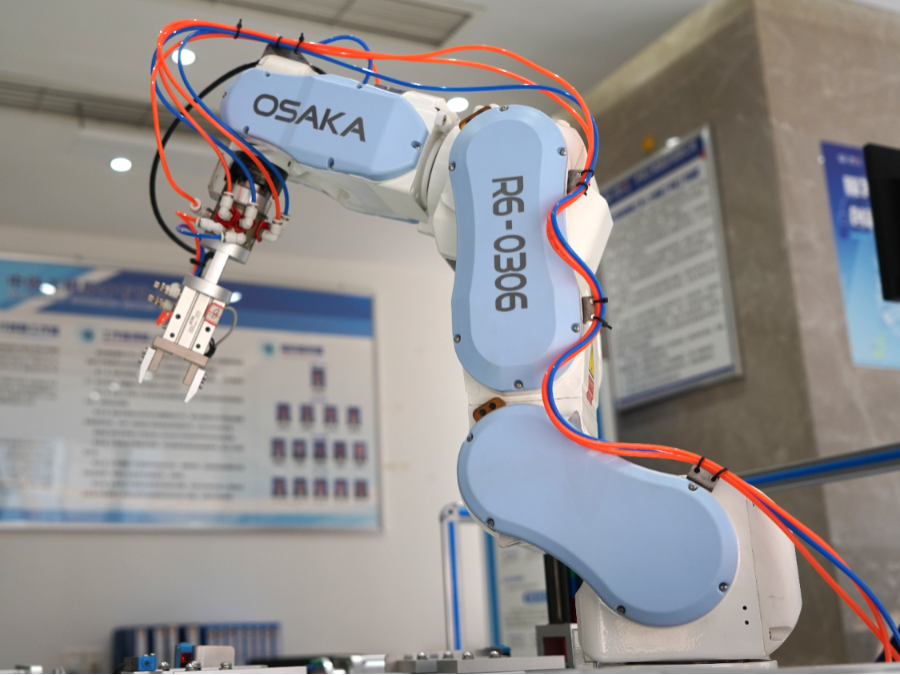

The robot features "saving labor, improving efficiency, stabilizing quality, saving materials, and ensuring safety" as its core highlights, equipped with high-precision laser line scanning cameras and autonomous vision systems to automatically identify welds. Lightweight design+dedicated track adaptation for narrow and complex spaces, built-in process database for intelligent parameter matching, and one click start for unmanned automated welding.

Adopting a gantry structure, combined with a dual machine collaborative mode, relying on self-developed machine vision reverse modeling, teaching free technology, and core technology of "model driven+robot vision", it does not require complex teaching and programming, automatically scans workpieces to identify welds, plans welding paths, and intelligently avoids obstacles. At the same time, it supports one click operation, solves frequent production changes, lifting and alignment problems, and is widely suitable for steel bridges, shipbuilding, construction and other fields, especially for flat workpieces such as bridge diaphragms.

Ground rail welding robot, specially designed for large quantities of irregular structural components, adopts a "dual robot+seventh axis ground rail+positioner" architecture, and performs synchronous welding on both sides. Offline programming seamlessly integrates with contact positioning, achieving four sided welding and one-time molding with one clamping, achieving "one clamping, multiple welding". It is the best choice for welding components such as guardrail uprights and slender members with both quality and efficiency.

Efficient Pioneer in Production and Manufacturing

This production line consists of imported sawing and drilling integrated equipment and a fully automatic rail transportation system, which can achieve fully automatic horizontal loading and unloading of 100 meter raw materials and high-speed rail sawing. While accurately controlling the length, it also completes the processing of steel rail head holes, greatly reducing the labor intensity of employees. It can achieve a 10% increase in raw material utilization rate and a production efficiency increase of more than 120%.

As the first fully intelligent bolt hot forging rolling and cold heading production line in China, this production line has an annual production capacity of 30000 tons. The entire production process covers cold heading, tooth rolling, heat treatment, surface treatment, packaging, and intelligent finished product warehouse, and the AGV automatic logistics system is fully connected throughout the entire process. Under the unified scheduling of MES system, efficient collaboration of equipment, logistics, and warehousing is achieved throughout the entire chain, building a modern workshop benchmark that is unmanned, green, and technologically upgraded.

Construction construction 'weapon for tackling difficulties'

This equipment has pioneered the construction of prefabricated buildings for subway stations. It adopts a double truss main beam structure and is equipped with 8 "legs" that can be independently extended and retracted, walking horizontally and vertically. It can independently extend and retract, climb hills and cross levels, and flexibly cope with various complex construction conditions such as uneven steps, tower crane areas, and cast-in-place hollow sections; And integrate 72 sensors and 50 cameras to build an intelligent "network hub", equipped with Beidou differential positioning correction system and variable frequency speed regulation technology, achieving precise construction and smooth operation, with a measurement accuracy of up to 10 millimeters, greatly improving the level of construction automation and intelligence.

The robot adopts a tracked chassis for movement and integrates serial multi axis robotic arm control technology, integrating key technologies such as 3D camera scanning and upper computer parametric programming, offline spraying trajectory planning, AGV autonomous positioning and automatic correction, and remote monitoring through a visualized cloud platform. The robot can autonomously move to the job position, quickly identify the spraying area through a 3D camera, and automatically generate corresponding control programs by the upper computer, thus completing the spraying task accurately and efficiently. This system significantly improves the quality, efficiency, reliability, and safety of spraying operations, and is suitable for various industrial spraying scenarios.

Intelligent Helper for Training Inspection

This platform is equipped with industrial control components such as servo motion modules, industrial robots, machine vision modules, and frequency converters, highly reproducing industrial field application scenarios. The simulation, experimentation, and research of industrial bus applications, robot applications, machine vision, and multi axis collaborative control technologies have been achieved, which can be used for practical training of specialized technologies related to shield tunneling machines, continuous belt conveyors, and distributed power electric locomotives. This strengthens the research and reserve of cutting-edge industrial control technologies, helps cultivate excellent technical personnel, and enhances the competitiveness of core talents in enterprises.Editor/Bian Wenjun

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~