- Microchannel reactors increase chemical yield by 20%, digital twin technology anticipates equipment failures, and membrane separation

- From what to manufacture to how to manufacture - reshaping the essence of production through process enhancement, digital twin

Amidst the noisy wave of the chemical industry focusing on new energy materials, a more profound industrial transformation is quietly brewing in the core area of the production process. As many companies focus on end products such as battery chemicals and photovoltaic materials, the new track that truly determines future competitiveness is gradually becoming clear - that is, the intelligent reconstruction and green innovation of the chemical production process itself. This is not only a technological upgrade, but also a strategic turning point for the entire industry to fundamentally transform from "what to manufacture" to "how to manufacture".

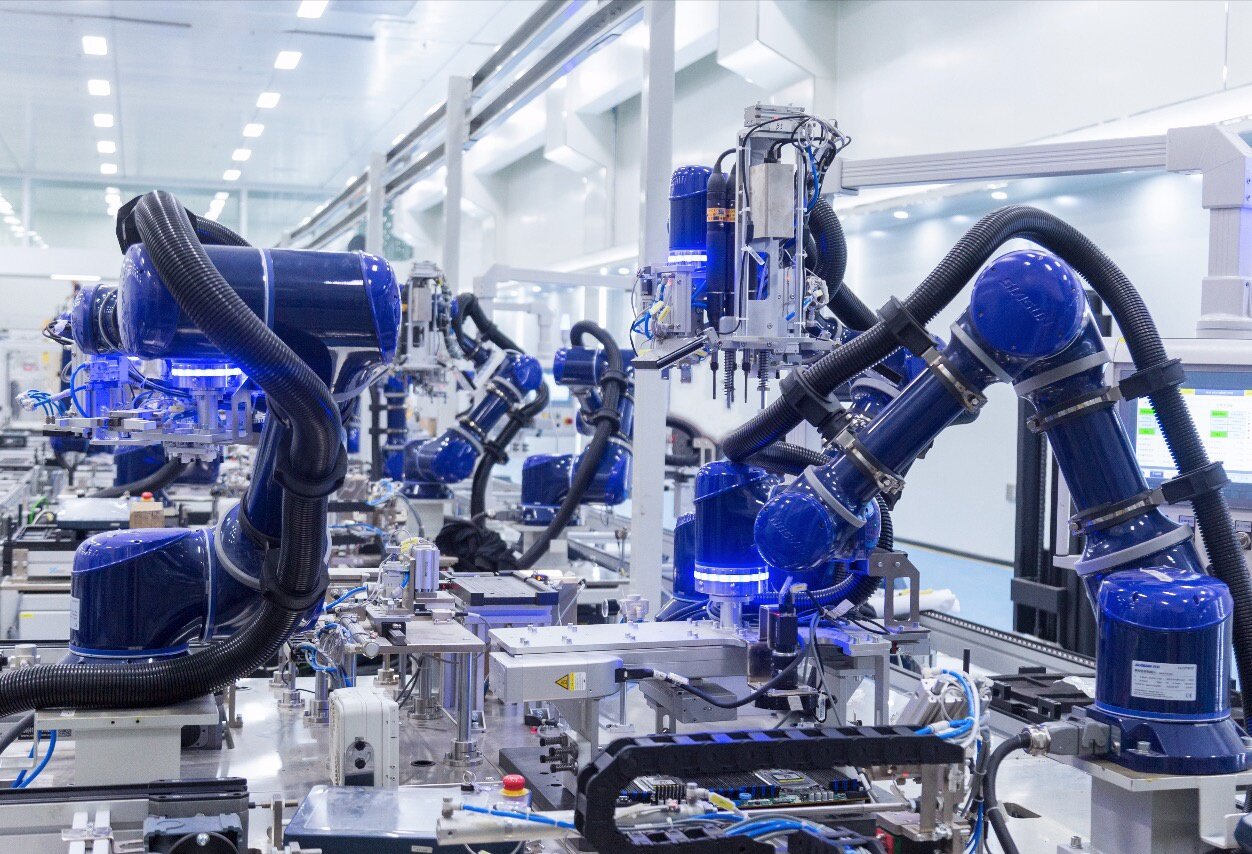

The production efficiency revolution led by continuous flow technology

The kettle type intermittent operation mode commonly used in traditional chemical production is being overturned by more efficient and precise continuous flow processes. Taking a certain fine chemical production enterprise as an example, the enterprise successfully increased the yield of a specific reaction from 75% to over 90% by using microchannel reactors instead of traditional large reactors, while compressing the reaction time from hours to minutes. This change not only significantly improves production efficiency and product quality, but also significantly reduces the generation of by-products by strengthening mass and heat transfer processes. While improving intrinsic safety levels, it also reduces raw material consumption and waste generation, reflecting the forefront trend of modern chemical engineering towards microscale and integrated development.

New paradigm of intelligent operation empowered by artificial intelligence

The deep integration of digital twins and artificial intelligence technology is redefining the operational management mode of chemical production. The practice of a large polyolefin production enterprise in China shows that by constructing a high-precision reactor digital twin model and integrating real-time production data, the system can dynamically simulate and predict the temperature field and concentration field of the polymerization process. When abnormal fluctuations in reaction temperature are detected, artificial intelligence algorithms can not only provide timely warnings, but also accurately identify potential root causes such as instantaneous deviations in catalyst injection systems or early signs of heat exchanger fouling. This enables the operation and maintenance team to take preventive intervention measures, effectively avoiding unplanned parking accidents and elevating the production process from relying on manual experience judgment to a new stage of data-driven precision control.

Sustainable Development Transformation Guided by Resource Regeneration

Faced with the dual challenges of global resource constraints and environmental pressures, the chemical industry is accelerating its transition from a linear economy model to a circular economy system. Taking polyvinyl chloride production enterprises as an example, by introducing advanced membrane separation and pervaporation technologies, efficient recovery and resource utilization of chlorinated vinyl monomer waste gas and wastewater generated during the production process have been successfully achieved.

This technological breakthrough not only enables enterprises to meet increasingly strict environmental emission standards, but also converts waste that originally needed to be incinerated into raw material resources that can be reused in the production process. While reducing the environmental footprint, it creates new economic benefits and provides a practical and feasible technological path for the green transformation of high energy consuming process industries. Keywords: social commentary

In the critical period of deep adjustment of the global chemical industry pattern in 2025, this industrial transformation driven by production efficiency revolution, intelligent operation innovation, and circular economy transformation is redefining the competition rules of the industry. Enterprises that can establish systematic advantages in process innovation, digital system construction, and resource recycling will not only be able to cope with current market and environmental challenges, but also take the lead in future development in this silent and profound industrial upgrading. This transformation may not be as eye-catching as new product development, but its reshaping effect on the industry landscape will be more profound and lasting. Editor/Yang Beihua

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~